9

4EXP70EN - 9/2023

4 Transportation, Storage and

Lifting

Check and document any damages in the transport packages

or dampeners. Contact the transportation company in case of

damage. When new or unused dampeners are sitting idle for

long periods, the following procedures should be complied

with:

1. Prior to storage, thoroughly drain dampeners of any and

all water.

2. Indoor storage is required. For unfavourable

environment, cover the equipment with protective

tarpaulin that will allow proper air circulation.

3. Protect the equipment from temperature and humidity

extremes and exposure to excessive dust, moisture,

vibration, sunlight, ozone and solvents.

4. Cover the flange openings.

5. Do not store any objects on top of the rubber hoses.

6. Before operation clean the dampener.

When storing used dampeners, wash them with fresh water

and follow the steps above. For storage periods greater than

36 months, please contact Valmet Flow Control as the rubber

parts need to be changed before use.

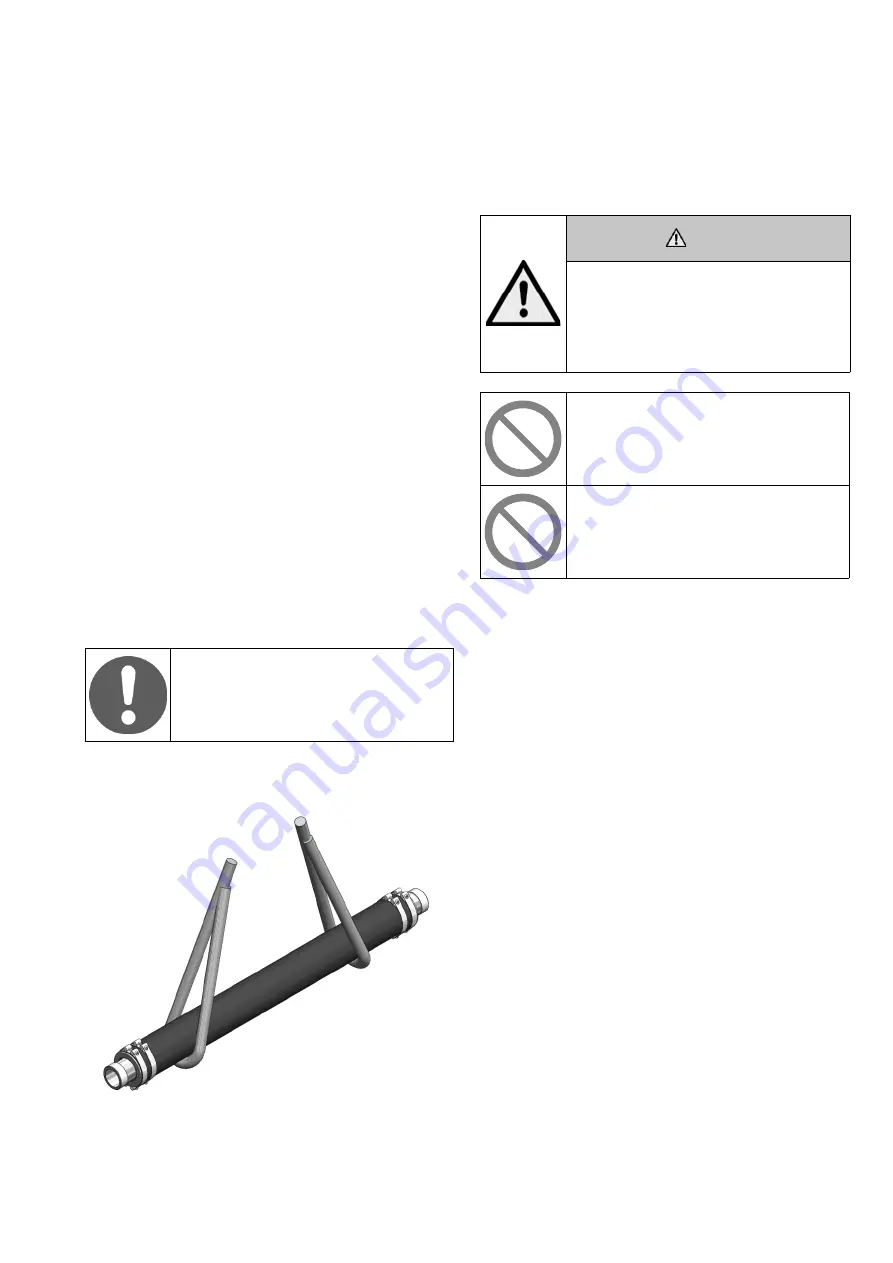

Lifting equipment must be used for dampeners weighing

over 25kg.

Lift the dampeners securely from the cover hose (part 2). Use

soft straps for lifting as shown in Figure 4. Lifting example.

Figure 4. Lifting example.

Do not attach lifting equipment to the bore as it can damage

the dampener. For Expulse™ dampener dimensions and

weighs refer to

Appendix A

.

5 Installation

WARNING!

High pressure injection hazard.

Do not use higher pressure than rated for the dampener.

Higher pressures can cause serious damage to the

equipment and harm to operating personnel.

Do not pressurise the pipeline before the dampener is

properly installed.

Do not install the Flowrox Expulse™ dampener on the

feed side of a pump. The dampener is not designed to

work under vacuum may be damaged.

Do not twist or rotate the dampener with any tools if the

other end is attached to a pipeline. The dampener can be

damaged.

5.1 General

Flowrox Expulse™ inline pulsation dampeners are normally

delivered fully assembled and ready for use. Only personnel

with appropriate training are allowed to install the

dampeners.

If the dampener is delivered disassembled it must

be assembled in accordance with the manufacturer’s

instructions.

Flowrox Expulse™ dampeners include connections with

threaded connectors.

Reserve enough space for safe installation and maintenance.

See

Appendix A

for Expulse™ dampener dimensions.

Summary of Contents for Flowrox Expulse Series

Page 17: ...17 4EXP70EN 9 2023...

Page 18: ...4EXP70EN 9 2023 18...

Page 19: ...19 4EXP70EN 9 2023...