VALLOX 90 SE

Parts list for VALLOX 90 SE

CO

2

Carbon dioxide sensor

Adjustment range 500...2000 ppm (900)

Option

Carbon dioxide control

Adjustment interval 1...15 min (10)

G4, F7

Filter

Supply air G4 + F7

Standard

Extract air G4

Standard

FG

Damper motor

HR bypass automation

Standard

24 V, 2 W, 4 Nm

H

Control panel

Setting, operation, display

Standard

LP2

Post-heating radiator

Tubeheater 900 W

Option

HR

Heat recovery cell

Counter-current cell, efficiency >80 %

Standard

EF

Extract air fan (DC – direct current)

qv =92 dm

3

/s (50 Pa)

Standard

%RH

Humidity sensor

Automatic / Adjustment range 1...99%

Option

Humidity control

Adjustment interval 1...15 min. (10)

TE1

Temperature sensor

Exhaust air temperature

Standard

Heat recovery defrosting

Adjustment range –6...+15

°

C (3)

Preheating control

Adjustment range –6…+15

°

C (5)

TE2

Temperature sensor

Supply air temperature

Standard

TE3

Temperature sensor

Outdoor air temperature

Standard

TE4

Temperature sensor

Extract air temperature

Standard

SF

Supply air fan (DC – direct current)

qv =75 dm

3

/s (50 Pa)

Standard

S

Fireplace / booster switch

Functions as either a fireplace

Standard

or booster switch (fireplace switch)

LP1

Preheating radiator

Tubeheater, 1000 W

Standard

© VALLOX • We reserve the right to make changes without prior notification.

0

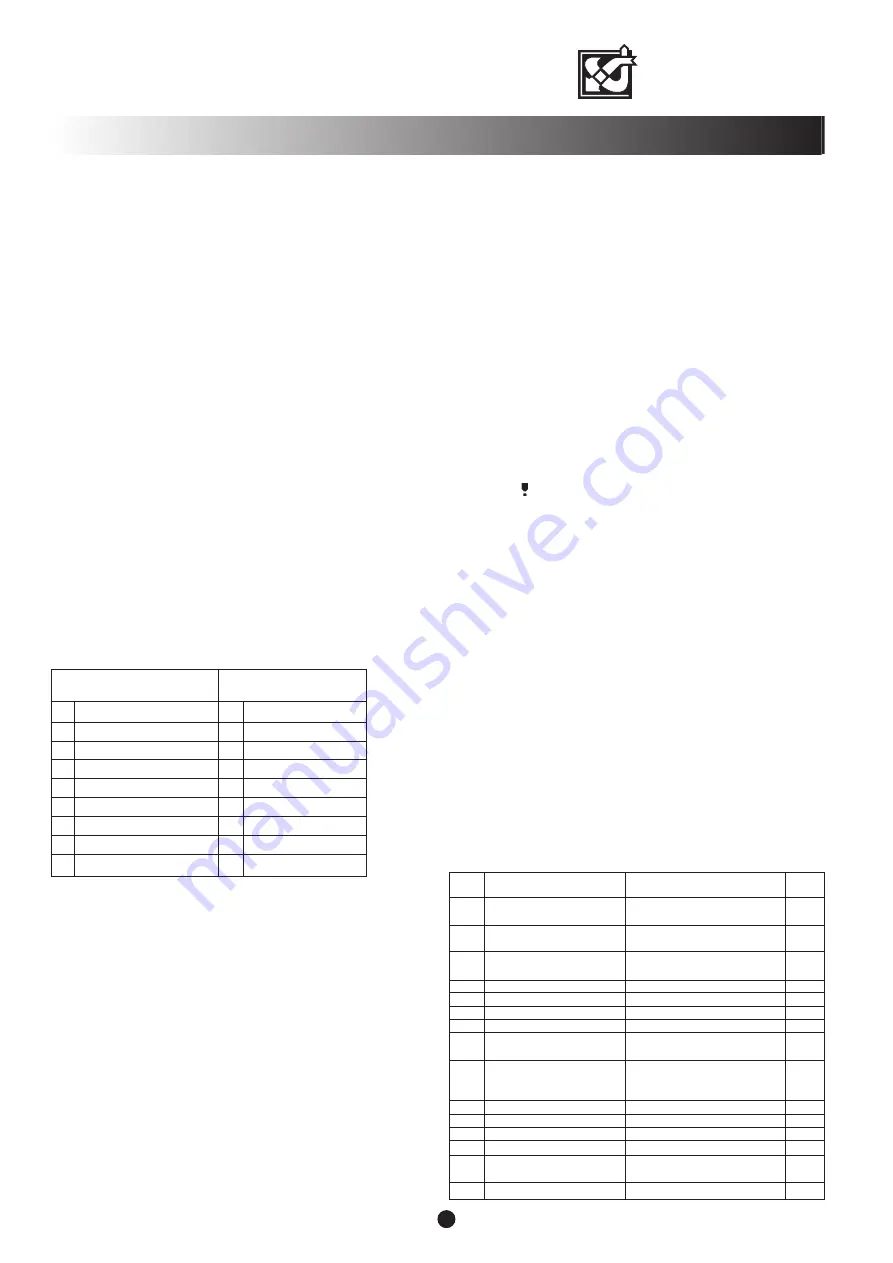

0.20...1.25 VDC

1

1.75...2.25 VDC

2 2.75...3.25 VDC

3 3.75...4.25 VDC

4 4.75...5.25 VDC

5 5.75...6.25 VDC

6 6.75...7.25

VDC

7

7.75...8.25 VDC

8 8.75...10.00

VDC

0 0.5...2.5 mA

1

3.5...4.5 mA

2

5.5...6.5 mA

3 7.5...8.5 mA

4 9.5...10.5 mA

5 11.5...12.5

mA

6 13.5...14.5

mA

7 15.5..16.5

mA

8 17.5...20.0

mA

Voltage and current signal values (selection in the motherboard)

Voltage values for each fan speed:

Current signal values

for each fan speed:

11

DESCRIPTION OF OPERATION VALLOX 90 SE

Control of operation

Power supply to the unit can be controlled with a contactor in the

distribution panel if needed, e.g. with a timer programme. After starting,

the unit first operates at minimum power. After that power is adjusted

based either on the measurement data from air quality sensors and/or on

manual control at the control panel.

Fan speed adjustment

Manual control

Fan speed of the ventilation unit is controlled in 8 steps at control panel H.

Week clock control

The fan power of the ventilation unit is controlled in 8 steps using the week

clock in control panel H. The week clock can be used to programme the

desired fan power option for each hour in the day.

Carbon dioxide and humidity control

The fan power of the ventilation unit is controlled in multiple steps

depending on load and based on the measurement results of the air

quality sensors (CO

2

and %RH sensors) located in the ventilation zone. The

aim is to keep carbon dioxide and/or humidity content in the zone below

the setpoint defined at the control panel H. One or more modes of control

may be used simultaneously. The dominant mode is the one demanding

boosting. Ventilation can be adjusted in a maximum of 8 steps. Fan speed

varies depending on load between the basic and maximum fan speeds.

The base and maximum fan speeds can be set at the desired level at

control panel H.

Control through voltage or current signal

The fan power of the ventilation unit is controlled in 8 steps with a voltage

signal of 0...10 VDC, or with a current signal of 0...20 mA. However,

when automatic adjustments are enabled, fan capacity cannot be raised

above the set maximum fan speed. Voltage or current signal control is used

to control base fan speed. This means that fan speed can be raised when

necessary, but not lowered, by the manual, CO

2

and %RH controls.

Supply air temperature

Supply air temperature can be controlled with either constant

temperature control or cascade control.

Supply air constant temperature control

The control centre of the unit controls the operation of post-heating unit

LP2 (option) on the basis of the measurement data given by temperature

sensor TE2, aiming at keeping supply air temperature at the temperature

value set at control panel H (+10…+30

°

C).

Supply air cascade control

The control unit directs the operation of post-heating unit LP2 on the basis

of the measurement data given by extract air sensor TE4, aiming at

keeping extract air temperature at the temperature value set at control

panel H (+10…+30 ºC).

Heat recovery bypass

Heat recovery is enabled whenever post-heating has been switched on.

Automatic heat recovery bypass is active whenever post-heating has

been switched off and outdoor temperature exceeds the setpoint (to be

set at +0...+25

°

C). In this case, the control unit directs the operation of

damper motor FG on the basis of measurement results given by outdoor

temperature sensor TE3 and extract air temperature sensor TE4. The aim

is to get as cool supply air to the ventilation zone as possible. Heat

recovery is, however, on whenever outdoor temperature is below the limit

set, or whenever outdoor air is warmer than extract air.

Heat recovery antifreeze

Active when outdoor temperature is less than 0

°

C. The control centre of

the unit controls the operation of preheating unit LP1 on the basis of the

measurement data of temperature sensors TE1 and TE3, preventing

freezing alerts and the stopping of supply air fan SF. If the capacity of

preheating unit LP1 is not sufficient, or if it has been taken out of service,

the control centre intermittently stops supply air fan SF on the basis of the

measuring data on temperature sensors TE1 and TE3, thereby preventing

the heat recovery cell from freezing.

As soon as the risk passes, the fan restarts automatically. The threshold

temperature for defrosting (-6…+15 ºC) and the difference area

(1…10 ºC) can be set at control panel H. When fan SF stops, power

supply from radiator LP1 is stopped and post-heating radiator LP2

continues heating.

Heating units LP1 and LP2

Heating units are tubeheaters and they might be burning hot.

Alarms

The symbol ( ) appearing in the main display of the control panel

reminds of the need for maintenance of the unit. The reminder interval

can be set between 1 and 15 months. The factory setting is 4 months. This

function is always active. The fault signal relay gives potential-free alarm

indications on the following fault conditions:

• Alarm of high carbon dioxide content (> 5000 ppm) switches the relay

at 1-second intervals. The fans stop. This is reset by switching off the unit.

• In other fault situations, such as sensor faults, the contacts of the relay

close.

Booster or fireplace switch function

The booster or fireplace switch function of the ventilation unit is controlled

either at control panel H and/or separate switch S, which can be

connected to the connection box of the unit. The mode of operation of the

switch is selected at control panel H. The booster switch function raises

fan speed to the set maximum fan speed for 45 minutes. The fireplace

switch stops the extract air fan for 15 minutes and produces overpressure

in the ventilation zone.

LON remote monitoring control can be implemented with a VALLOX LON

converter.

Code

Name

Technical data

Standard /

(factory settings in parentheses)

Option