3.1.3

Motor Parameters

Configuration items in this menu relate to the motor and turntable.

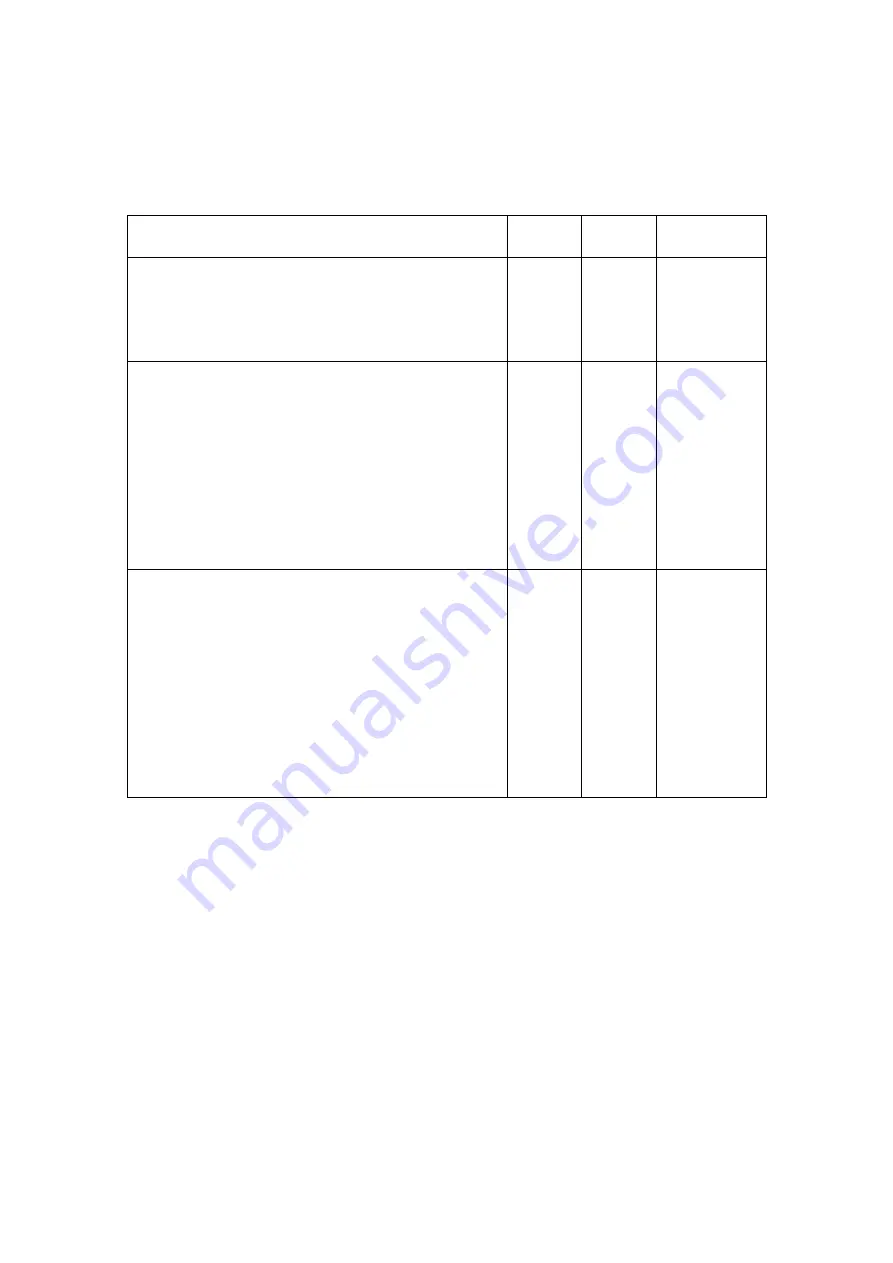

Parameter / Description

Units

Range

Default

value

Winding 1 phase is always starts at 0 degrees.

This is a statement. Subsequent windings

probably require 90, 180, 270 degree phase angles

respectively depending if you are using 2,3,4

phase motors.

-

-

-

Enter winding %d, phase angle in deg

Windings probably require 90, 180, 270-degree

phase angles respectively depending if you are

using 2,3,4 phase motors.

Slight adjustment of phase angles can reduce

motor vibration. Start with the defaults and adjust

on test. If you can hold the motor in your hand

this is the best way to determine vibration.

Listening to the motor noise is also a good

indication.

degrees 45 –

300

90, 180, 270

for each

phase 2, 3, 4

respectively

Enter winding n, drive voltage (rms)

The voltage that should be applied to each

winding. For 110v synchronous motors 85v rms is

a good starting point. Slight adjustment of phase

voltages can reduce motor vibration. Start with

the defaults and adjust on test. If you can hold the

motor in your hand this is the best way to

determine vibration. Listening to the motor noise

is also a good indication. However, if you set to

low a voltage then the platter will fail to turn or

not make it up to 45 rpm.

Volts

(rms)

5-100

85

3.1.4

PID Control parameters

Proportional, Integral, Derivative control is an adaptive speed control algorithm. It

uses the IR platter rotation sensor to adjust the frequency fed to the motor to help

maintain an accurate 33.3 or 45 rpm rotation speed. Further details on setting the

values are provided in a separate section. We recommend initial testing is done only

with motor drive and IR sensor to get the system initially working. Once you get an

rpm indication in the region of 33 or 45 rpm from the IR sensor, only then proceed to

configure PID. To get to the parameters in this setup section you must answer Y to

“Are you using PID and platter sensor?” in the system parameters section.