Start-up 7

0020257319_02 Hydraulic station Installation and maintenance instructions

33

6.14

Connecting the domestic hot water cylinder

1.

Connect the temperature sensor (VR10) for the do-

mestic hot water cylinder to the corresponding connec-

tion for cable harness X22 on the control PCB.

2.

If an external current anode is installed in the domestic

hot water cylinder, connect it to X313 or X314 on the

power supply PCB.

◁

The connection plug is included in the bag of small

parts.

6.15

Connecting the external prioritising diverter

valve (optional)

▶

Connect the external prioritising diverter valve to X14 on

the control PCB.

–

The connection to a permanently live phase "L" with

230 V and to a switched phase "S" is available.

Phase "S" is actuated by an internal relay and

releases 230 V.

6.16

Using the additional relays

▶

If required, consult the installation diagram handbook

that is contained in the scope of delivery for the system

control and the handbook for the optional module.

6.17

Connecting cascades

▶

If you want to use cascades (max. seven units), you must

connect the eBUS line to contact X100 via the

VR32b

bus coupler (accessory).

6.18

Sealing the power supply PCB

1.

Tighten all of the screws on the strain relief clamps.

2.

Close the cover for the electronics box on the power

supply PCB.

3.

Hinge the electronics box back up.

6.19

Checking the electrical installation

▶

After the installation is complete, check the electrical in-

stallation to ensure that the connections that have been

established are secured properly and are sufficiently in-

sulated.

7

Start-up

7.1

Activating screed drying without the outdoor

unit and system control

Caution.

Risk of damage to the product caused by

impermissible purging

Without purging the heating circuit, the sys-

tem may become damaged.

▶

If the screed drying is activated without a

system control, purge the system manu-

ally. No automatic purging takes place.

Screed drying

.

–

You can use this function to "dry heat" freshly laid screed

in accordance with the construction regulations, accord-

ing to a defined time and temperature schedule, without

having a system control or the outdoor unit connected.

When screed drying is activated, all the selected operating

modes are interrupted. The function controls the flow tem-

perature of the controlled heating circuit according to a pre-

set programme, regardless of the outdoor temperature.

The display shows the target flow temperature. You can

manually set the current day.

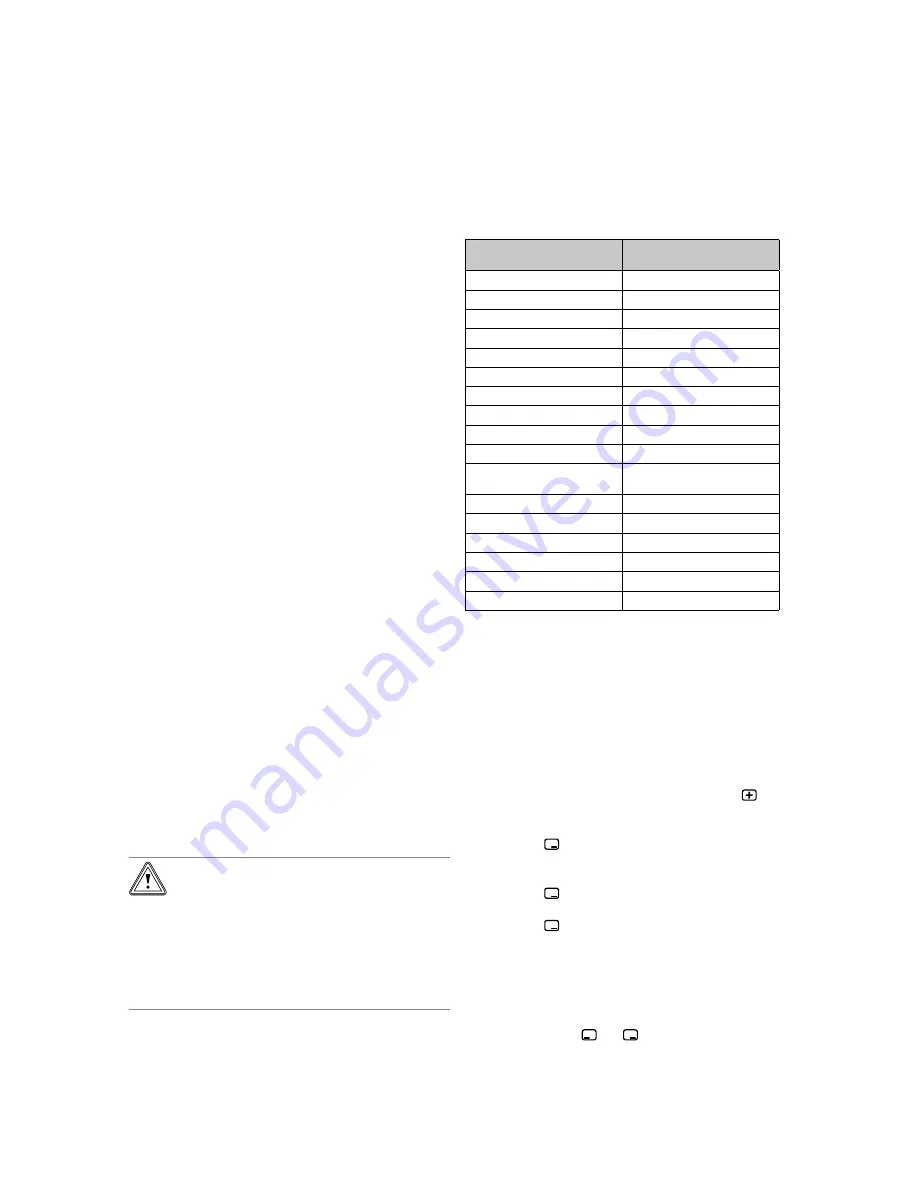

Days after starting the func-

tion

Target flow temperature for

this day [°C]

1

25

2

30

3

35

4

40

5

45

6

–

12

45

13

40

14

35

15

30

16

25

17

–

23

10 (frost protection function,

pump in operation)

24

30

25

35

26

40

27

45

28

35

29

25

The day is always changed at 00:00, irrespective of when

the function starts.

After a mains Off/On, screed drying starts with the last active

day.

The function ends automatically when the last day of the

temperature profile has elapsed (day = 29) or if you set the

start day to 0 (day = 0).

7.1.1

Activating the screed drying

1.

Press the reset button.

2.

When restarting the display, press and hold the

but-

ton until the language selection opens.

3.

Set the required language. (

→

Page 36)

4.

Press the

button in order to select the power supply

for the back-up boiler.

–

230 V

5.

Press the

button in order to select the output of the

back-up boiler.

6.

Press the

button in order to select the start day for

the screed drying.

◁

The screed drying is started and the display shows

the current flow temperature and the right-hand

status bar shows the system pressure.

▽

In the current programme, the current status mes-

sages for the system can be called up in the display.

▶

Press the

and

buttons in order to display

the status messages.