VAG Installation and Operating Instructions • 9

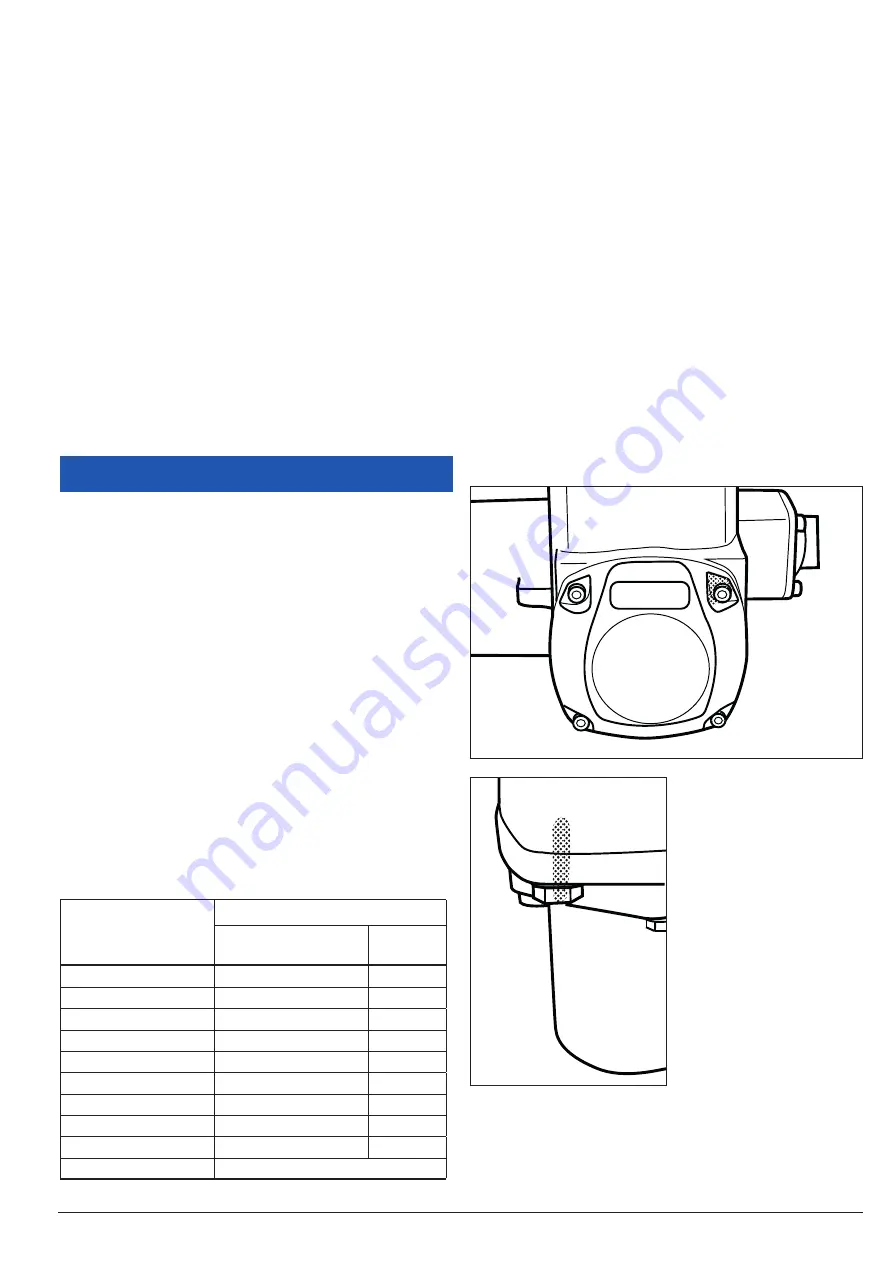

Picture 12: Screws sealed to the electric drive on delivery

Penstock dimension A

x A [mm]

Max. operating torque

non-rising stem

rising

stem

150 … 300

30 Nm

30 Nm

400 … 600

40 Nm

40 Nm

700

60 Nm

60 Nm

800, 900

100 Nm

100 Nm

1000, 1200

120 Nm

100 Nm

1300, 1400

180 Nm

180 Nm

1500

200 Nm

200 Nm

1600

220 Nm

220 Nm

1700, 1800

250 Nm

250 Nm

1900 … 4000

defined in project documentation

Table 4 Operating torques

Especially after repair work but also during the set-up of new

equipment, the pipeline system must be cleared again with the

Penstock fully open. As a standard the Penstock is closed by tur-

ning the operating square end clockwise (via an operating key, a

handwheel or an electric actuator).

The dimensions of the stems and actuators allow the operation of

the Penstock by one person using the handwheel. Extensions for

operation are not permissible and may cause damage to the Pen-

stock due to excessive loads.

Limit stops in the Penstock limit the travel. Trying to turn these

components beyond the limit stops using excessive force may

damage the penstock. Check the proper function of the limit

stops by opening and closing the Penstock several times.

The dimensions of the stems and actuators allow the operation of

the Penstock by one person using the handwheel. Extensions for

operation are not permissible and may cause damage to the Pen-

stock due to excessive loads.

Limit stops in the Penstock limit the travel. Trying to turn these

components beyond the limit stops using excessive force may

damage the penstock. Check the proper function of the limit

stops by opening and closing the Penstock several times.

6 Actuators

6.1 General

Directly mounted actuators/drives or VAG extension spindles in

many different types are available for the VAG EROX

®

plus

Pen-

stock.

Actuators mounted directly to the penstock bridge (pneumatic,

hydraulic or electric actuators) are only designed for the operating

conditions specified in the order. The adjustment of the limit stops

(OPEN, CLOSED) must not be changed without the manufacturer‘s

consent.

If the Penstock and the actuator are delivered separately, e.g. on

a headstock, the limit switches must be adjusted on site before

the actuator is put into operation.

The limit switches are adjusted in compliance with the operation

instructions of the respective manufacturer of the actuator, such

as AUMA, Rotork etc. When a gear unit is retrofitted, its nominal

torque and the adjustment of the limit stops (OPEN and CLOSED)

must be adapted to the Penstock.

For detailed information about drives and actuators, please refer

to the operation manuals of the manufacturers (e.g. AUMA,...).

Non-compliance with these Introductions may lead to physical in-

jury and death and/or cause damage to the equipment. If actua-

tors powered by external energy (electric, pneumatic, hydraulic)

have to be disassembled from the Penstock, the safety instruc-

tions in Chapter 1.1 must be observed and the external energy

source must be switched off.

6.2 Operation torques

Operation torques are the maximum required torques [in Nm] at

the drive stem at full differential pressure and with a calculated

safety factor. If required, please contact us to enquire about the

respective torques and/or controlling torques for electric actua-

tors.

6.3 Assembly of the electric actuator

The electric actuator is mounted to the bridge or to remote con-

trol components such as a ROTAG headstock.

The Penstock is switched off:

• path-dependent in open position

• torque-dependent in closed position.