6 / 8

P/N 1061018 • REV E • ISS 14JUL11

8. Strip 3/8 in. of insulation from each wire.

9. Determine the correct wiring, and then insert the wires

under the appropriate screw terminals. See "Wiring" and

Figure 4 to Figure 6.

10. Tighten both screws to secure the base to the wall plate.

11. Replace the detector cover.

12. Apply power. The LED should flash green for

approximately four seconds, and then pulse green.

13. If required by the AHJ or local codes, affix the supplied CO

Warning Label (P/N 10634757) in proximity to the

detector.

14. Test in accordance with “Testing” below.

Wiring

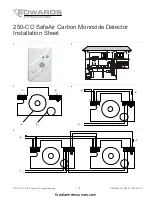

There are three typical wiring configurations:

•

Single device and single zone (Figure 4)

•

Multiple devices in a single zone (Figure 5)

•

Multiple devices with separate alarm and trouble zones

(Figure 6)

Notification

Notification of carbon monoxide detectors should be consistent

with NFPA 720 and the local AHJ. Notification zones should be

consistent with the emergency plan for the protected premises.

Maintenance

Note:

The 250-CO is shipped from the factory as an

assembled unit; it contains no user-serviceable parts and

should not be disassembled.

Clean the outside of the detector each month with a clean cloth

(either dry or dampened with water) to keep openings free from

dust and dirt.

Do not paint the detector or expose it to cleaning solutions.

CO detector replacement

The 250-CO SafeAir Carbon Monoxide Detector has a long-life

carbon monoxide electrochemical sensor. Replace the detector

with a new 250-CO detector after six years from the date of

manufacture (found on the product label on the back of the

detector) or when the control panel goes into trouble and an

audible/visible annunciation occurs signaling “end of life”.

Testing

WARNING:

To reduce the risk of carbon monoxide poisoning,

test alarm operation when not in use for 10 days or more.

Test the detector by pushing the test button after installation

and once a week to verify that it is functioning properly. If the

detector fails the test, verify all connections, wait briefly then try

again. If the detector fails again, replace it.

Notify all persons and facilities that receive alarm and trouble

signals before beginning the test (to prevent unnecessary

response).

To test the trouble relay:

1. Momentarily

disconnect

the power supply from the

detector and verify that the common trouble relay opens.

2. Verify that the panel reacts correctly to the relay activation.

Test/hush button:

(Refer to Figure 7.) Use the test/hush

button to test the detector and silence an activated detector.

When in alarm, momentarily pushing the test/hush button

silences the integral sounder for five minutes. The red alarm

light stays on, and if CO is still present after five minutes, the

detector once again sounds in the temporal-four pattern. The

detector automatically resets when CO is no longer detected.

Three different tests can be performed by pressing the

test/hush button. How long the button is pressed determines

which tests are performed. See Table 2.

Table 2: Press duration and resulting test

Duration Test

Description

Short press

Buzzer test only

Generates the temporal-four

pattern twice.

Two seconds Buzzer test

Fast CO test

Generates the temporal-four

pattern twice.

While in the fast CO test mode, a

functional carbon monoxide gas

test can be performed using a can

of CO testing agent [1].

Five seconds Buzzer test

Fast CO test

Alarm relay test

Generates the temporal-four

pattern twice.

While in the fast CO test mode, a

functional carbon monoxide gas

test can be performed using a can

of CO testing agent [1].

Activates the alarm relay.

[1] Use the UL-certified “Solo C6” canned CO product from SDi

To test the buzzer:

1. Momentarily

press

the test/hush button.

The sounder generates four quick beeps, followed by five

seconds of silence, and then four quick beeps.

firealarmresources.com