9. Operating Your Transmitter

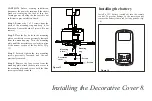

Figure 16

Figure 15

b) From the back of the transmitter, with the fan’s

power off, restore power to the fan. Press and

hold “SET” button for about 5 seconds and

release. If optional light kit is installed, the light

kit will flash twice and the signal light on the

hand held transmitter will come on when the

button is pressed. The fan has completed the

pairing process with the remote control and is

ready for use. (Fig. 16)

NOTE:

If the self calibration test failed, turn the

AC power off; restore power and process the self

calibration test again.

NOTE:

During self calibration test, the remote is

non-fuctional.

NOTE:

The learning frequency function and self

calibration test will continue to retain the last set

frequency and calibration set even when the AC

power is shut off. If the frequency is changed the

self calibration test will occur again.

Over 80W protection: When the receiver detects

motor power consumption which is greater than

80W, the receiver power will be stopped and

operation will immediately discontinue. Wait for

5 seconds and then turn the receiver power back

on.

Remote Control Button Definitions:

These six buttons are used to set the fan speed as

follows:

I = minimum speed

II = low speed

III = medium low speed

IV = medium speed

V = medium high speed

VI = high speed

button: Turns the fan off.

button: Controls fan direction.

"D" and "ON" dip switch: The "D" selection is the

light dimmable selection for LED light only. The

"ON" selection is the light on only (no dimmable

function). (Fig. 16)

Your DC brushless motor is equipped with an

automatically learned type remote control. There are

no frequency switches on the receiver; the receiver

unit will automatically scan the frequency from the

remote control if any changes are made. The

frequency settings on the transmitter should be

changed

ONLY in case of interference or if a

second or more ceiling fans with the same type of

control system are installed in the same structure.

Setting the Remote Control

Follow the below steps to set the remote control:

The auto learning function will only mandate within

60 seconds when turning the fan’s AC power ON.

a) Select desired frequency from the transmitter. The

dip switches can be set to 16 different combinations.

(Fig. 16)

ON ECE

1 2 3 4

ON ECE

1 2 3 4