Vision™ OPLC™

Unitronics

9

Opening the Controller

Before performing these actions, touch a grounded object to discharge any electrostatic

charge.

Avoid touching the PCB board directly. Hold the PCB board by its connectors.

1. Turn off the power supply, disconnect, and dismount the controller.

2. The back cover of the controller comprises 4 screws, located in the corners. Remove the screws,

and pull off the back cover.

Changing I/O Settings

1. The I/O board of the controller is now exposed, enabling you to change I/O settings according to

the jumpers shown on page 5.

Changing Communication Settings

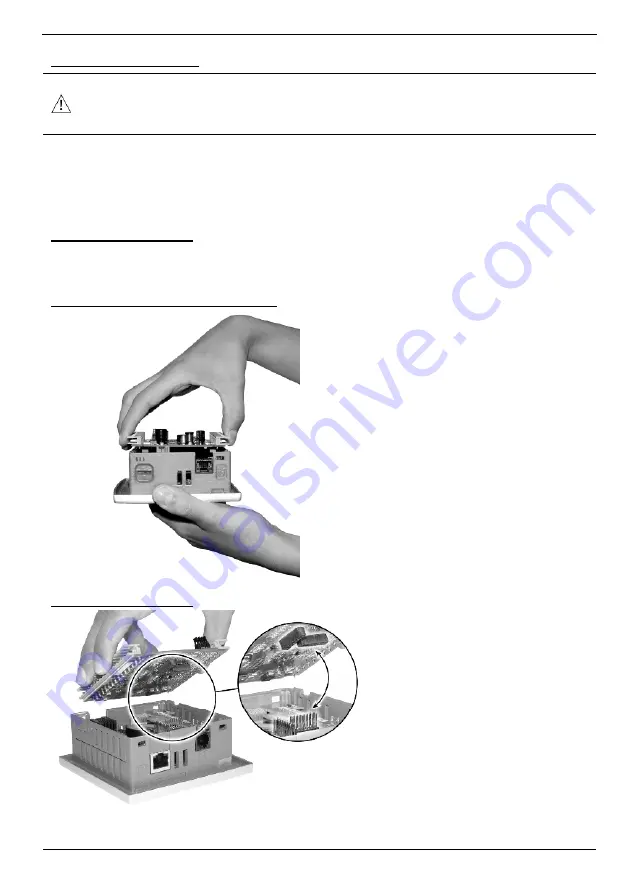

1. To access the communication

jumpers, hold the I/O PCB board by

its top and bottom connectors and

steadily pull the board off.

2. Locate the jumpers, and then change

the settings as required. Jumper

settings are shown on page 8.

Closing the Controller

1. Gently replace the board. Make

certain that the pins fit correctly into

their matching receptacle.

Do not force the board into place;

doing so may damage the

controller.

2. Replace the back cover of the

controller and fasten the corner

screws.

Note that you must replace the back cover securely before powering up the controller.