5

INSTALLATION

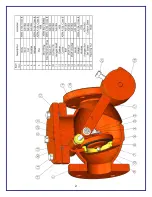

A. Check that valve end joints conform to the mating pipe and verify that ends

are clean and sound. All 7700 series valves are supplied with flat face flanges

with ANSI class 125 drilling. Do not mate these valves to pipe or fittings with

raised face flanges.

B. Remove any material used to restrain the lever or pin during shipment and

storage. Attach any outside closing mechanism in proper position manually.

C. Closing mechanism should be checked to insure freedom of motion and

proper operation. Cover bolts shall be checked for any loose joints.

D. When handling the valve, do not use the outside mechanisms for lifting.

E. It is necessary to install the valve in proper orientation with regard to flow

direction. Please note flow arrow on side of body.

F. Prepare pipe ends per pipe manufacturer’s instructions, and install valve as

per appropriate instructions for the specific joint. All piping should be properly

supported to avoid line stress on the valve. Do not use valves as a jack to force

a pipeline in position.

G. Standard wrenches and or sockets are to be used to tighten all nuts and bolts.

Fasteners are to be tightened in a crisscrossed pattern to insure balance loading

of bolts.

OPERATION

Once in the pipeline, the swing check valve will operate as flow conditions

dictate. The valve will open as the pressure on the upstream side of the disc

overcomes the downstream side. The valve will close as the situation reverses

itself or the pressure equalizes.

These valves are self contained units. Outside levers, weights, springs or hinge

pins should never be used to manually operate the valve or restrict its operation.

External shields and surrounding piping should not interfere with the free

operation of external apparatus of the valves.

MAINTENANCE

The system is designed to be trouble free with minimum care. Frequency of

inspection should be based on the operational characteristics of the system, i.e.

Summary of Contents for 7700 Series

Page 2: ...2...