IMP120-17

www.ueonline.com

Option M210 Indicator for Differential Pressure Controls,

Span Adjustment

(See Figure 6). To adjust indication for maximum accuracy at any

desired set point, follow steps 1 thru 3 listed below:

1. Remove front window and gasket (four screws) to gain access

to span adjustment.

2. Connect device to calibrated gauge and set required differential

pressure.

3. Using a screwdriver, slowly turn the span adjustment to obtain

required indication. Remount the front gasket and window.

NOTE:

Spanning adjustment will not affect the mid-range indication.

The adjustment is factory calibrated and sealed to indicate tampering.

DO NOT FORCE SPAN ADJUSTMENT, SINCE PERMANENT

DEFORMATION OF THE LINKAGE MECHANISM MAY RESULT.

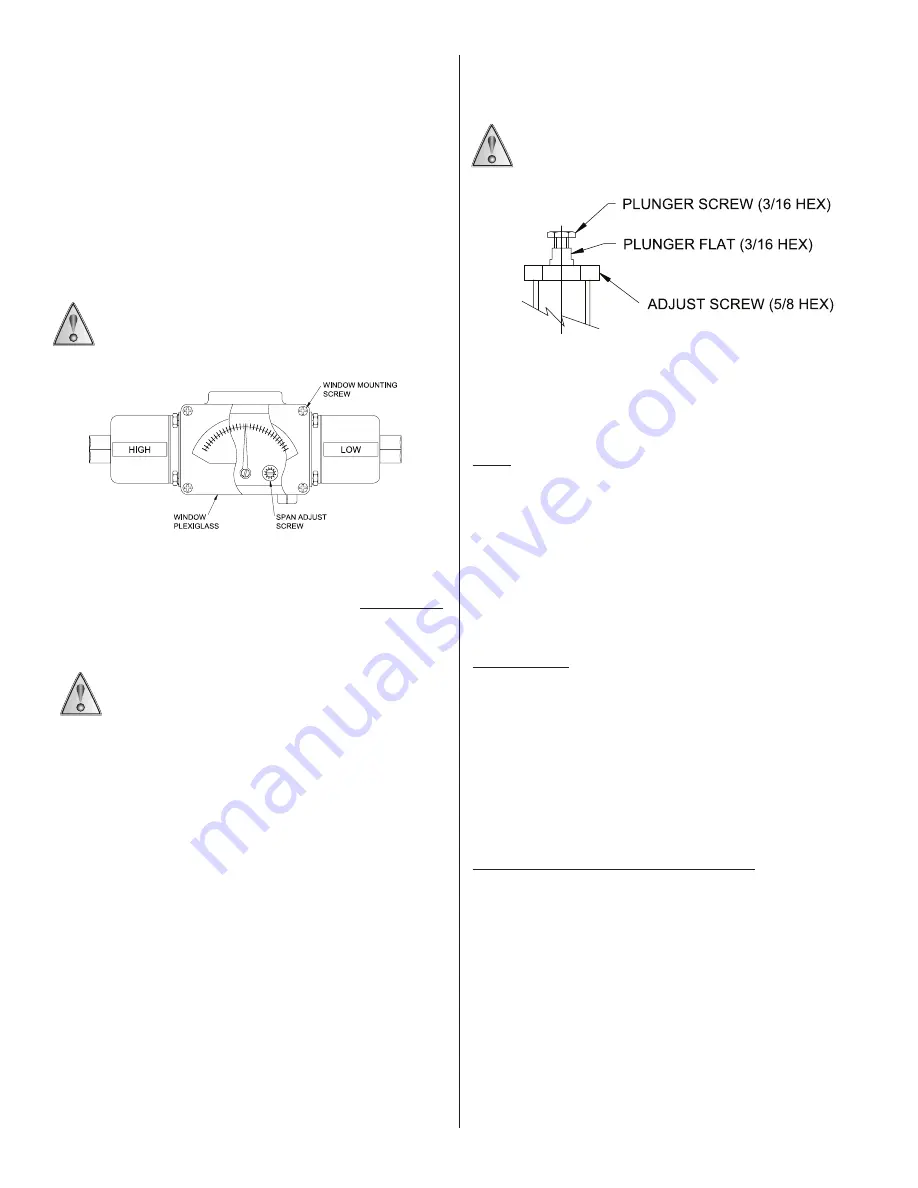

RE-GAPPING PROCEDURE

Tools Needed

5/8” Open End Wrench

3/16” Open End Wrench (2)

GAPPING IS FACTORY-SET AND CRITICAL TO THE FUNCTION

OF THE SWITCH. THIS PROCEDURE SHOULD ONLY BE

PERFORMED IF THE PLUNGER HAS ACCIDENTALLY BEEN

ADJUSTED.

1. Loosen adjustment lock.

2. Turn 5/8” hex adjustment screw clockwise to approximately

midrange. This puts a load on the sensor and exposes the

plunger flats. (See Figure 7).

3. Using a 3/16” wrench on the plunger flats and a 3/16” wrench on

the plunger hex screw, turn hex counter-clockwise from plunger

until micro-switch actuates. If microswitch has already actuated,

turn plunger hex screw clockwise until microswitch deactuates.

4. Continue per following instructions, depending on model.

Models 171-174, 521-525, 531-535, and 540-548

Turn hex clockwise an additional 1-1/2 flats from this point. This will

provide a 5-9 mil gap.

Models 680, 701-705, 356-376, 612, 616, 270, 274

Turn hex clockwise 3 flats from this point (approximately 1/2 turn).

This will provide a 14-16 mil gap.

Re-Gapping Procedure for J120/J120K

Figure 7

Models 183-189, 190-194, 483-489, 490-494,565-567

Turn hex clockwise 1 flat from this point. This will provide a 4-7 mil

gap.

CONTACT FACTORY FOR ASSISTANCE WITH MODELS

NOT SHOWN ABOVE.

ZONE HAZARDOUS LOCATIONS FLAMEPROOF GAP AND JOINT

DETAILS

120’S

Activation Plunger to adjustment screw hole gap joints: 1.140in/28.96mm

min length by 0.0039in/0.099mm max annular gap

Plunger Guide to enclosure through threaded joints: minimum 8 ½ fully

engaged threads

Cover to enclosure through threaded joints: minimum 7 ½ fully engaged

threads

121’S & 122’S

Activation Plunger to enclosure through hole gap joints: 1.000in/25.40mm

min length by 0.0030in/0.076mm max annular gap

Adjustment shaft to shaft through hole gap joints: 1.050in/26.67mm min.

length by 0.0035in/0.089mm max. annular gap

Cover to enclosure through threaded joints: minimum 7 ½ fully engaged

threads

MANUAL RESET OPTION 1530 (120’S,121’S)

Reset pivot to pivot guide through hole gap joints: 1.118in/28.40mm min.

length by 0.0036in/0.091mm max annular gap

Reset guide to enclosure through threaded joints: 8 fully engaged threads

Figure 6

Option M210