035-20464-002 Rev. A (1004)

Unitary Products Group

5

TABLES 2 & 3 is to be used as a guide only to help the installer deter-

mine if the duct sizes are large enough to obtain the proper air flow

(CFM) through the furnace. TABLES 2 & 3 IS NOT to be used to design

ductwork for the building where the furnace is being installed. There are

several variables associated with proper duct sizing that are not

included in the tables. To properly design the ductwork for the building,

refer to the ASHRAE Fundamentals Handbook, Chapter on “DUCT

DESIGN” or a company that specializes in Residential and Modular

Home duct designs.

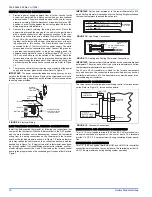

IMPORTANT:

The minimum plenum height is 12” (30.5 cm). The fur-

nace will not operate properly on a shorter plenum height. The mini-

mum recommended rectangular duct height is 4 inches (10 cm)

attached to the plenum.

IMPORTANT:

The air temperature rise should be taken only after the

furnace has been operating for at least 15 minutes. Temperatures and

external static pressures should be taken 6” (15 cm) past the first bend

from the furnace in the supply duct and the return duct. If an external fil-

ter box or an electronic air cleaner is installed, take the return air read-

ings before the filter box or air cleaner.

If a matching cooling coil is used, it may be placed directly on the fur-

nace outlet and sealed to prevent leakage. Follow the coil instructions

for installing the supply plenum. On all installations without a coil, a

removable access panel is recommended in the outlet duct such that

smoke or reflected light would be observable inside the casing to indi-

cate the presence of leaks in the heat exchanger. This access cover

shall be attached in such a manner as to prevent leaks.

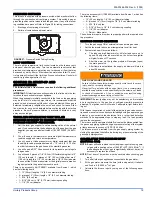

The supply air temperature MUST NEVER exceed the Maximum

Supply Air Temperature, specified on the nameplate.

Operating the furnace above the maximum supply air temperature

will cause the heat exchanger to overheat, causing premature heat

exchanger failure. Improper duct sizing, dirty air filters, incorrect

manifold pressure, incorrect gas orifice and/or a faulty limit switch

can cause the furnace to operate above the maximum supply air

temperature. Refer to sections II, III and XI for additional informa-

tion on correcting the problem.

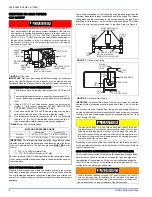

FIGURE 1:

Dimensions

All dimensions are in inches and are approximate.

FRONT

LEFT SIDE

RIGHT SIDE

D

B

20

40

A

28-1/2

3/4

14-3/4

5-3/8

(VENT CONNECTIONS)

POWER WIRING

7/8” HOLE

2-1/2

ACCESS

WIRING

7/8” K.O.

16

8-3/4

T’STAT WIRING

7/8” K.O.

1-1/8

2-1/4

14

23-1/2

32-1/2

2

13-3/4

GAS INLET

1-1/4 x 2-1/2

20

B

C

A

3/4”

FLANGE

BOTTOM IMAGE

(FRONT)

TOP IMAGE

(FRONT)

VENT

CONNECTION

(Vent Size)

D

F

E

28-1/2

23

(WITH K.O.

REMOVED)

TABLE 4:

Cabinet and Duct Dimensions

BTUH (kW)

Input/Output

CFM (m

3

/min)

Cabinet

Size

Cabinet Dimension

A

A (cm)

B

B (cm)

C

C (cm)

D

D (cm)

F

F (cm)

E

E (cm)

40/32 (11.71/9.38)

1200 (33.98)

A

14 1/2

36.8

13 1/4

33.6

10 1/8

25.7

4.0

10.2

10 1/8

25.7

3 3/4

9.5

60/48 (17.6/14.07)

1200 (33.98)

A

14 1/2

36.8

13 1/4

33.6

10 1/8

25.7

4.0

10.2

10 1/8

25.7

3 3/4

9.5

80/64 (23.42/18.76)

1200 (33.98)

A

14 1/2

36.8

13 1/4

33.6

10 1/8

25.7

4.0

10.2

10 1/8

25.7

3 3/4

9.5

80/64 (23.42/18.76)

1600 (45.31)

B

17 1/2

44.4

16 1/4

41.3

13 1/8

33.3

4.0

10.2

11 5/8

29.5

3 3/4

9.5

80/64

(23.42/18.76) 2200

(62.30)

C

21 53.3 19

3/4 50.2 16

5/8 42.2 4.0 10.2 13

3/8 34 3

3/4 9.5

100/80 (29.28/23.42)

1200 (33.98)

B

17 1/2

44.4

16 1/4

41.3

13 1/8

33.3

4.0

10.2

11 5/8

29.5

3 3/4

9.5

100/80 (29.28/23.42)

1600 (45.31)

B

17 1/2

44.4

16 1/4

41.3

13 1/8

33.3

4.0

10.2

11 5/8

29.5

3 3/4

9.5

100/80

(29.28/23.42) 2000

(56.63)

C

21 53.3 19

3/4 50.2 16

5/8 42.2 4.0 10.2 13

3/8 34 3

3/4 9.5

115/92

(33.70/26.96) 1600

(45.31)

C

21 53.3 19

3/4 50.2 16

5/8 42.2 4.0 10.2 13

3/8 34 3

3/4 9.5

115/92

(33.70/26.96) 2000

(56.63)

C

21 53.3 19

3/4 50.2 16

5/8 42.2 4.0 10.2 13

3/8 34 3

3/4 9.5

130/104 (38.09/30.48)

2000 (56.63)

D

24 1/2

62.2

23 1/4

59.1

20 1/8

51.1

4.0

10.2

15 1/8

27.6

3 3/4

9.5