53

24” PARTS DIAGRAM AND LIST

Item #

Description

Part #

1

Back splash panel

UGP-DWSJ13253

2

Back splash panel cover

UGP-'DCY14274-1

3

Cooking panel

UGP-'DWSJ13254-4

4

Cooking panel stop plate

UGP-DCY14226

5

Control panel

UGP-WSJ13340-SY

6

Knob bezel

UGP-DCY07049

7

Liner front panel

UGP-DWSJ13256

8

Burner fixed board

UGP-CY14531

9

Liner back panel

UGP-WSJ13341

10

Liner left panel

UGP-WSJ13349

11

Liner right panel

UGP-WSJ13350

12

Liner top panel

UGP-WSJ13342

13

Feet fasten beam (left)

UGP-DCY14237

14

Feet fasten beam (right)

UGP-DCY14238

15

Chiminey A

UGP-CY14536

16

Chiminey B

UGP-CY14537

17

Liner fasten beam

UGP-CY14538

18

Liner heat-insulated panel

UGP-CY14539

19

Feet fasten beam (left)

UGP-DWSJ13245

20

Feet fasten beam (right)

UGP-DWSJ13246

21

Oven flame spreader

UGP-DCY14248

22

Thermostat clip

UGP-DCY14249

23

Back panel fixed support

UGP-'DCY14250

24

Oven floor

UGP-WSJ13343

25

Back panel

UGP-CY14549

26

Oven door

UGP-DWSJ13260

27

Oven door fasten plate

UGP-DCY14295

28

Oven door glass support

UGP-DCY14296

29

Door heat-insulated fiber left press panel

UGP-DCY14297

30

Door heat-insulated fiber right press panel UGP-DCY14298

31

Door heat-insulated fiber upper press panel UGP-DCY14299

32

Door heat-insulated fiber bottom press panelUGP-DCY14300

33

cover on the top of oven door

UGP-DWSJ13261

34

Oven door inner panel

UGP-DWSJ13262

35

Drawer door

UGP-WSJ13344

36

Drawer inner panel

UGP-WSJ13345

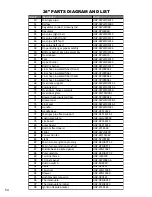

37

Anti tip bracket

UGP-DCY14269

38

Oven rack fixed part

UGP-DCY14270

39

Regulator fixed part

UGP-DCY14271

40

Cast iron grate with dimplets

UGP-DWWJ01019-1

41

130 burner assembly

UGP-DWWJ01293

42

100 burner assembly

UGP-DWWJ01294

43

55 burner assembly

UGP-DWWJ01295

44

Nozzle

UGP-DPJ24003-DPJ24120

45

Ignition Needle for biggest burner

UGP-DXQJ9901

46

Ignition needle clip

UGP-DWJ9901

47

Knob

UGP-DWWS07001

48

Gas valve

UGP-DPJ99170

49

Thermostat valve

UGP-DWWJ01114-6

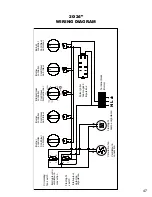

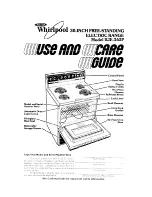

Summary of Contents for Classic Plus

Page 21: ...21 WALL CLEARANCES continued 24 ...

Page 22: ...WALL CLEARANCES continued 22 ...

Page 49: ...20 PARTS DIAGRAM AND LIST 49 ...

Page 52: ...52 24 PARTS DIAGRAM AND LIST ...

Page 56: ...NOTES 56 ...