General unit data

Mains voltage

AC 230 V +10 % / -15 %

AC 120 V +10 % / -15 %

Mains frequency

50...60 Hz ±6 %

External primary fuse (Si)

6.3A (slow)

Power consumption

12 VA

Mounting orientation

optional

Weight

approx. 200 g

Degree of protection

IP40 (to be ensured through mounting)

Perm. cable lengths

max. 3m at line capacitance of 100 pF/m

Detector cable laid separately

10 m

Remote reset laid separately

20m

LMO14

LMO24

LMO44

Terminal 1

5 A

5 A

5 A

Terminals 3 and 8

3 A

5 A

5 A

Terminals 4, 5 and 10

1 A

1 A

1A

Terminals 6

1 A

1 A

2A

Flame supervision with QRB and QRC

QRB

QRC

Min. detector current required (with flame)

45 µA

70 µA

Min detector current permitted (without flame)

5.5 µA 5.5 µA

Max. possible with flame (tipically)

100 µA 100 µA

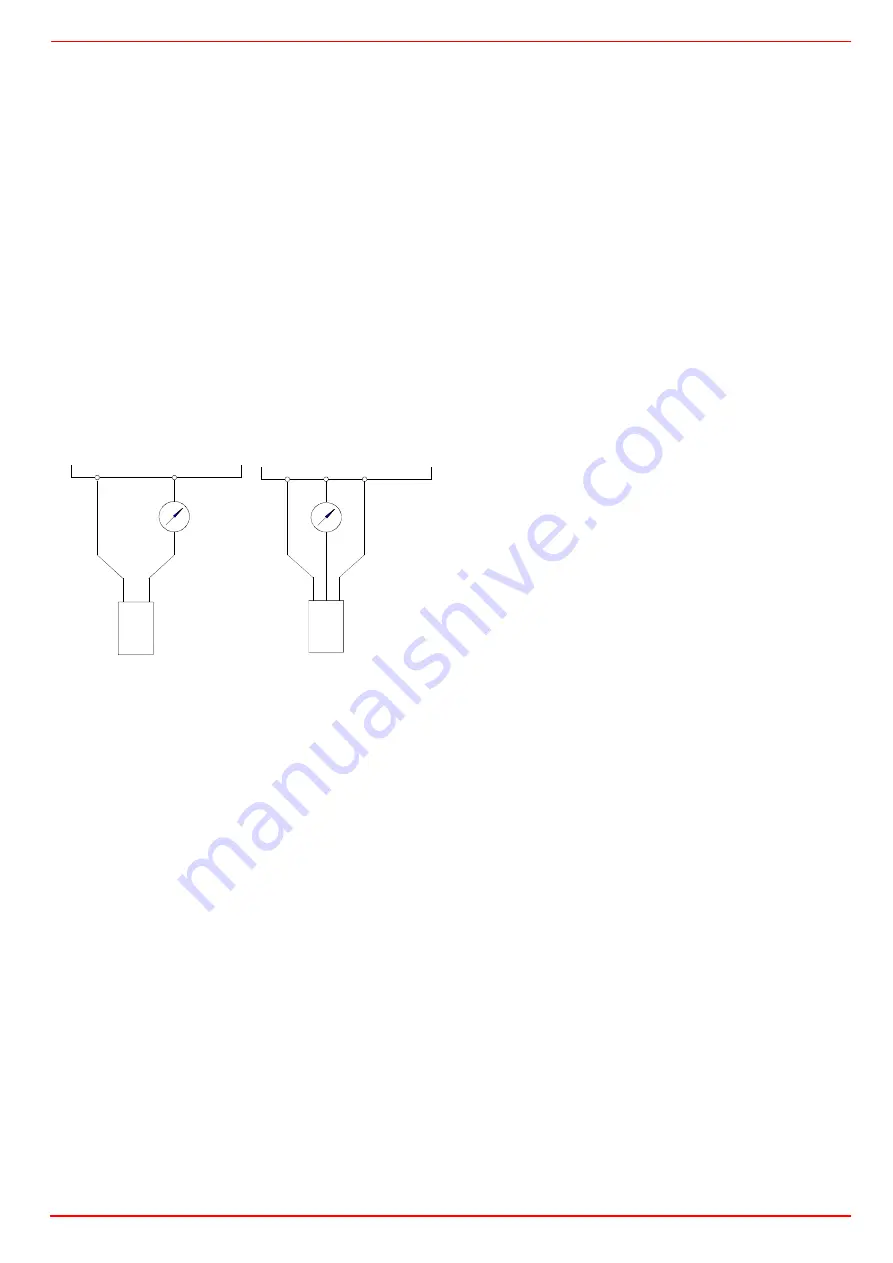

Measurement circuit for detector current

Key

µA DC

DC microamperometer with an internal

resistance of 5 k

max.

bl

Blue

sw

Black

br

Brown

LAL.. CONTROL BOX FOR OIL BURNERS

Use

Control and supervision of oil atomization burners

For burners of medium to high capacity

For intermittent operation (at least one controlled shutdown every 24

hours)

Universally applicable for multistage or modulating burners

Housing and plug-in base

Made of impact-proof and heat-resistance black plastic

Lockout reset button with viewing window; located behind it:

Lockout warning lamp

Lockout indicator coupled to the spindle of the sequence switch and

visible in the transparent lockout reset button

uses easy-to-remember symbols to indicate the type of fault and the

point in time lockout occurred

Base and plug-in section of the LAL... are designed such that only burner

controls of the LAL... family can be plugged in.

24 connection terminals

Auxiliary terminals «31» and «32»

3 earth terminals terminating in a lug for earthing the burner

3 neutral conductor terminals prewired to terminal 2

14 knockout holes for cable entry by means of cable glands

8 at the side

6 in the bottom of the base

6 lateral threaded knockout holes for cable entry glands Pg11 or M20

Operation

Flame detector and flame simulation test are made automatically during

burner off times and the prepurge time «t1». If loss of flame occurs during

operation, the burner control will initiate lockout. If automatic repetition of

the startup sequence is required, the clearly marked wire link on the plug-

in section of the LAL... must be cut away.

Pre-conditions for burner startup

Burner control is not in the lockout position

Sequence switch is in its start position (with LAL2 voltage is present at

terminals 11 and 12.

Air damper is closed; end switch «z» for the CLOSED position must

feed power from terminal 11 to terminal8.

Contact of the limit thermostat or pressure switch «W» and the con-

tacts of any other switching devices in the control loop between termi-

nals 4 and 5 must be closed e.g. a control contact for the oil

preheater’s temperature

Normally closed contact of the air pressure switch must be closed.

Startup sequence

Start command by «R»:

«R» closes the start control loop between terminals 4 and 5

The sequence switch starts to run

Only prepurging, fan motor at terminal 6 receives power

Pre- and postpurging, fan motor or flue gas fan at terminal 7 receives

power on completion of «t7»

On completion of «t16», the control command for opening the air dam-

per is delivered via terminal 9

Terminal 8 receives no power during the positioning time

The sequence switch continues to run only after the air damper has

fully closed.

t1

Prepurge time with air damper fully open:

The correct functioning of the flame supervision circuit is checked

during «t1»

The burner control will initiate lockout if correct functioning is not ensu-

red.

With LAL2:

Shortly after the beginning of «t1», the air pressure switch must change

over from terminal 13 to terminal 14 otherwise, the burner control will ini-

tiate lockout start of the air pressure check.

t3

Short preignition time:

«Z» must be connected to terminal 16, release of fuel via terminal 18.

12

11

LMO...

bl

µA DC

+

QRB...

7130v01/0700

sw

12

11

LMO...

1

sw

bl

br

µA DC

+

QRC1...

7130v02/0700