- 17 -

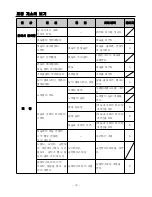

Problem

Cause

Check

Solution

Page

Needle

breakage

Improper needle

installation

Needle

facing,

height

Reinstall needle.

4

Bent needle

Blunt needle tip

jammed eye

Needle

Replace needle

4

Improper feed timing

_

Adjust feed timing.

8

Improper needle to

rotary hook timing

Needle bar stroke

Adjust needle to

rotary hook timing.

8

Needle bar height

Adjust needle to

rotary hook timing.

8

Needle to rotary

hook gap

Adjust needle to

rotary hook timing.

8

Thread wiper too high

Thread wiper

position

Adjust thread wiper

position with screw.

Thread

breakage

Improper threading

Threading

Rethread.

4

Bent needle

Blunt needle tip

jammed eye

Needle

Replace needle

4

Improper needle

installation

Needle

facing,

height

Reinstall needle.

4

Excessive needle

thread tension

Needle thread

tension

Adjust needle

thread tension.

6

Excessive bobbin

thread tension

Bobbin thread

tension

Adjust bobbin

thread tension.

6

Loose needle thread

Thread take-up

spring operation

Adjust thread

take-up spring.

6

Insufficient rotary hook

lubrication

Oil supply

Adjust oil supply.

2

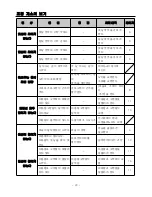

TROUBLESHOOTING GUIDE

Summary of Contents for LS2-H530

Page 2: ......

Page 4: ...5 off A S 34 2 40 25 OFF A S A S...

Page 26: ...16 4 4 8 8 8 8 4 4 4 6 6 6 2...

Page 28: ...18 4 4 1 4 4 8 8 8 6 6...

Page 30: ...20 6 6 6 6 puff 8 11 14 4 13 11 14 11...

Page 32: ...22 6 1 13 6 11 11 11 11...

Page 34: ...24...