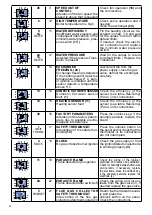

(F) 27

22

ERROR

Flow Gradient

Check if the pump switches off

suddenly.

(F) 23

23

Detected tab panel button pres-

sed for longer than 30 “

Check keypad and reset the

status of the buttons. Or repla-

ce the electronic board

(F) 53

24

Clogged Outlets

Check the Chimneys / Check

the trap.

(F) 55

25

No Calibration

GAC Calibration 4.3.1

(F) 18

26

Electrode earthed on the Burn-

er or presence of moisture

Check the distance between the burn-

er and the electrode, check for humid-

ity between drain wire and ceramic, if

necessary, replace the electrode.

(F) 43

27

During the ignition stage, ab-

normal flame extinguishing

has occurred 12 "consecutive"

times in a period of about 50

sec.

Check the gas pressure / any flue

gas recirculation in the chimney and

obstructions / condensation drain

/ electrode electrical connection /

electrode and burner earth / perform

GAC calibration chap. 4.3.1 / replace

the electrode and its connection /

replace the electronic board

BLOCK

28

Control circuit problems

Gas Valve

Check the Gas Valve connec

-

tions / Replace the Gas Valve

(3)

/ Replace the Modulation

Board

BLOCK

32

Gas Valve opening time beyond

limit time

Check the parts that generate the heat

requests (thermostats, electrovalve

limit switches, flow switch, etc.)

BLOCK

33

Flame loss with max ignition

value correction

Check the gas pressure / any flue

gas recirculation in the chimney and

obstructions / condensation drain

/ electrode electrical connection /

electrode and burner earth / perform

GAC calibration chap. 4.3.1 / replace

the electrode and its connection /

replace the electronic board

BLOCK

General block for unclassified

anomalies.

Replace Modulation Board.

ERRORS DISPLAYED ON REGOLAFACILE ONLY

-

75

-

Regolafacile external sensor

Replace the external probe /

Regolafacile

-

80

-

Regolafacile Internal Sensor

Replace Regolafacile

-

81

-

Eprom Error of Regolafacile

Replace Regolafacile

(*) if there is a condensation obstruction inside the flue gas manifold (before resetting) it is necessary

to proceed to a drying operation inside of the tank especially of the level sensor electrodes.

service

service

service

service

service

service

service

service