25

Instructions for the installer

3.17 - COMBUSTION AIR AND VENTILATION

OPENINGS

Provisions for combustion and ventiiation air must be made

in accordance with section 5.3, Air for Combustion and Venti-

lation, of the National Flue Gas Code, ANSI Z223.1/NFPA 54.,

or Sections 7.2, 7.3 or 7.4 of CAN/CSA-B149.1-05,

installation

Codes, or appiicabie provisions of the local building codes.

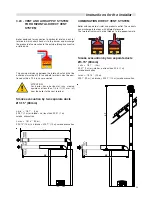

CAUTION

BOILER DAMAGE AND OPERATIONAL

FAILURES

Due to insufficient or improper openings for com-

bustion air and/or ventiiation of the boiler room.

Provisions for combustion air and ventiiation are

always required, regardiess whether the combu-

stion air is taken from the outside (sealed com-

bustion) or inside (room air for combustion).

Insufficient ventilation of the boiler room can lead

to high air temperatures. This can result in boiler

damage.

- Make sure that intake and exhaust openings

are sufficiently sized and no reduction or closu-

re of openings takes place.

- When the problem is not resolved, do not ope-

rate the boiler.

- Please note these restrictions and its dangers

to the operator of the boiler.

WARNING

BOILER DAMAGE !

Due to contaminated air.

- Boiler must be clear and free from combustible

materials, gasoline and other flammable vapors

and liquids, and corrosive liquids and vapors.

Never use chiorine and hydrocarbon containing

chemicals (such as spray chemicals, solution

and cleaning agents, paints, giues etc) in the

vicinity of the boiler.

- Do not store and use these chemicals in the

boiler room.

- Avoid excessive dust formation and buildup.

NOTICE

When one expects contaminated combustion air

(near swimming pools, chemical cleaning ope-

rations and hair salons),

sealed combustion operation is recommended.

DANGER

Fire danger due to flammable materials or liqui-

ds.

- Do not store flammable materials and liquids in

the immediate vicinity of the boiler.

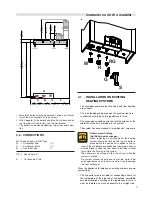

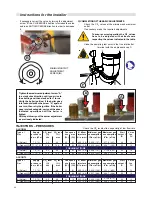

All Air from inside the Building (room air)

The closet shall be provided with two permanent openings

communicating directly with an additional room(s). The total

input of all gas utilization equipment installed in the combi-

ned space shall be considered in making this determination.

Each opening shall have a minimum free area of 1 square

inch per 1,000 Btu per hour of total input rating of all gas

utilization equipment in the confined space, but no less than

100 square inches. One opening shall commence within 12

inches (305 mm) of the top, and one opening shall commen-

ce within 12 inches (305 mm) of the bottom of the enclosure.

The minimum dimension of air openings shall be not less

than 4 inches (101 .6 mm).

All Air from Outdoor (seaied combustion)

The cioset shall be provided with two permanent openings,

one commencing within 12 inches (305 mm) from the top,

and one commencing within 12 inches (305 mm) from the

bottom of the enclosure. The openings shall communicate

directly, or by ducts, with the outdoors or spaces (crawi or

attic) that freely communicate with the outdoors.

The minimum dimension of air openings shall be no less

than 4 inches (101.6 mm).

1. Where directly communicating with the outdoors, each ope-

ning shall have a minimum free area of 1 square inch per

4,000 Btu/hr of total input rating of all equipment in the enclo-

sure.

2. Where communicating with the outdoors through vertical

ducts, each opening shall have a minimum free area of 1

square inch per 4,000 Btu/hr of total input

rating of ali equipment in the enclosure.

3. Where communicating with the outdoors through horizon

tal ducts, each opening shall have a minimum free area of 1

square inch per 2,000 Btu/hr of total input rating of ali equip-

ment in the enclosure.

4. Where ducts are used, they shall be of the same cross-

sectional area as the free area of the opening to which they

connect.