UT3500 series

User Manual

35

6.2 Stat

6.2.1 Process Capability Index

Process capability refers to the ability of process processing to meet processing quality. It

measures the internal consistency of process processing and the smallest fluctuation in

the most stable state. When the process is in a steady state, 99.73% of the product quality

characteristic values are scattered in the interval [

μ

-3

σ

,

μ

+3

σ

]

(

μ

is the overall mean value

of the product characteristic values, and

σ

is the overall standard deviation of the product

characteristic values). Almost all product characteristic values are within the range of 6

σ

.

Therefore, 6

σ

is usually used to represent process capability and the smaller the value,

the better.

Generally

Cp, CpK > 1.33 Process capability is sufficient.

1.00 < Cp, CpK

≦

1.33 Process capability is appropriate.

Cp, CpK

≦

1.00 Process capability is insufficient.

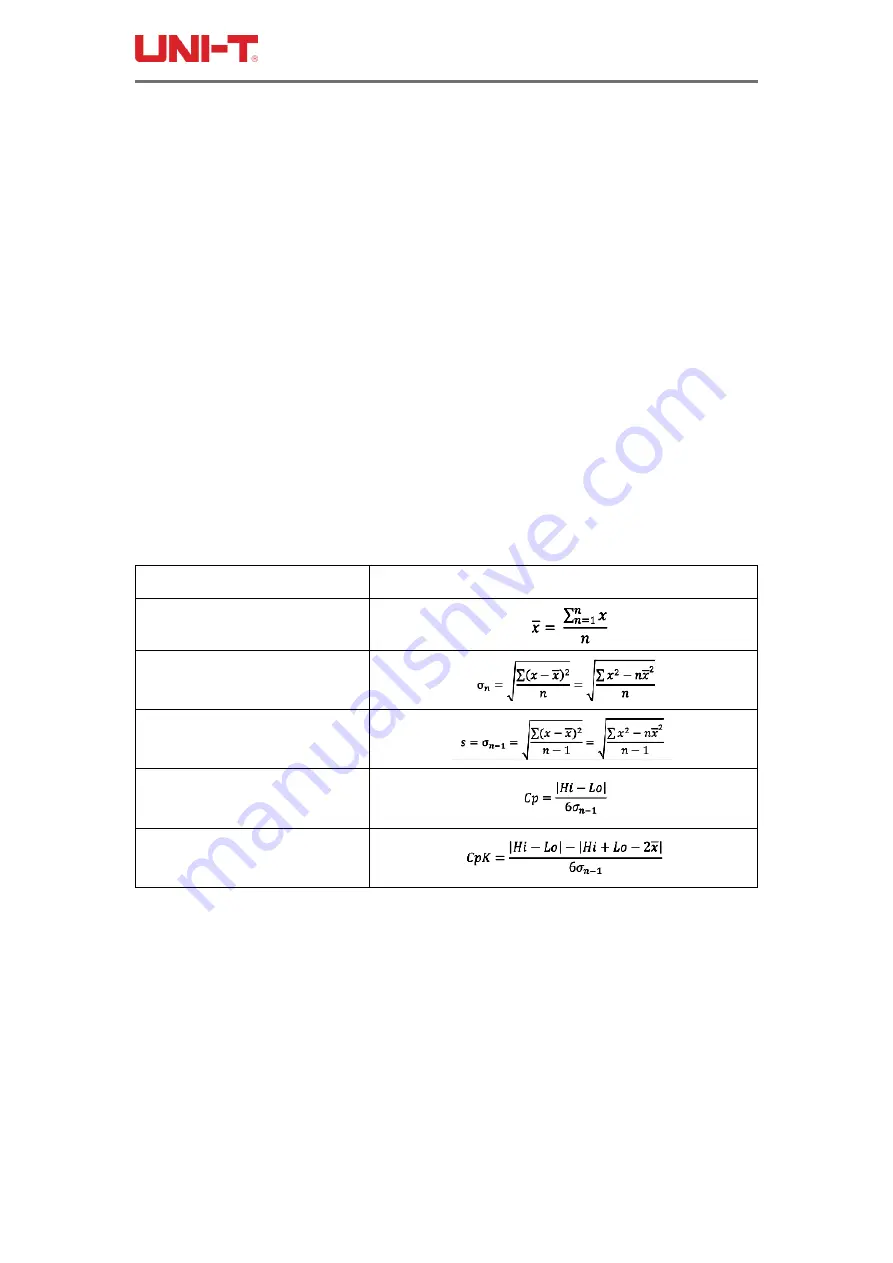

Process capability index and some related formulas:

Process Capability Index

Formulas

Average (Mean)

Population Standard Deviation

σ

n

Sample Standard Deviation

s(=

σ

n-1

)

Process Capability Index

(Deviation) Cp

Process Capability Index

(Offset) CpK

In the above formulas:

a) n represents valid data, that is, the value excluding overflow and open circuit. As long

as the data can be displayed on the screen, they are valid values.

b) Variable Hi and Lo in the Cp and CpK formulas are the actual value of the upper and

lower limits of the comparator. In the PER and ABS comparison mode, the actual value will

be converted from the nominal value. This value will participate in the calculation

regardless of whether the comparator is turned on.

c) When the sample standard deviation

σ

n-1=0, Cp=99.99, CpK=99.99.

d) When CpK <0, CpK = 0.