8

9-1. Maintenance

Confirm the following check points once a day.

(1)

Is there a leakage at the connection section with vacuum pump?

(2)

Do you find oil vapor or oil leaking out of connection hoses or pipes and the

machine body?

(3)

Do you hear abnormal noise?

Please take action of 12. ‘Failure and Countermeasure’ if you find it abnormal.

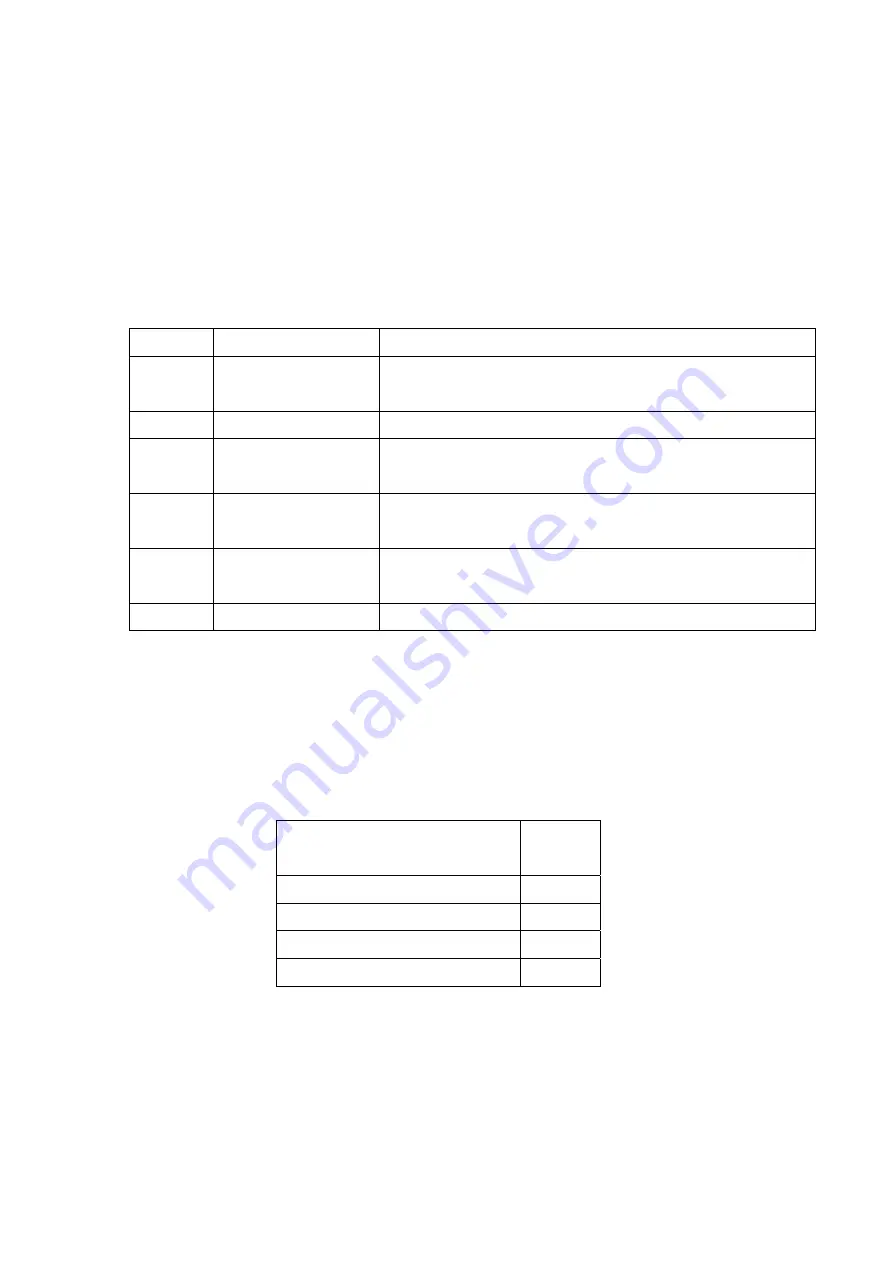

9-2. Regular check up

Check

points

Detail

①

Element

The condition of increase in pressure and oil

contamination

②

Oil pressure pump The condition of sucking and draining

③

Housing

Defect, leak, crack, damage or etc. The condition of

deterioration of O ring and such components.

④

Connection hose

and joints

The deterioration condition. The condition of

contamination.

⑤

Every piping

Crack, loose, breakage. The condition of

contamination

⑥

Pressure gauge

A gauge pointer goes out of order.

We suggest that overhaul should be performed every two years for longer lifetime of our

product.

Please ask us or our dealers for overhauling for this product is assembled of

mechanical

ingenuity.

9-3. List of Consumables

Description No.

of

units

Element 1

Pump connection hose

2

O-ring (AS-238)

1

O-ring (G-100)

1

9-4 When to replace elements

①

Replace elements when the pressure of circular pump in the outlet side reaches to

0.3MPa or more during operation.

②

Replace elements when the quality becomes inferior due to deterioration of water

separation membrane affected by the particles excluded from the above.

※

The O-rings are used between

filter case and housing head.