3

General -

1. Check for wear and deterioration.

Before each use, carefully inspect your harness for

signs of wear, deterioration, or evidence of impact

loading. Visually inspect for loose threads, pulled

rivets, burns, cuts, distortions, abrasions, or any other

evidence of chemical or physical deterioration that

may have weakened the material or assembly.

2. Inspect hardware for malfunctions and cracks.

Check all snap hooks, buckles and D-Rings.

3. Remove from service and replace all worn

or damaged equipment.

If any part does not pass inspection, immediately

remove the harness from service and destroy.

Specific -

1. Stitching and webbing.

Check stitching for broken, burned, cut or pulled

stitches. Broken strands appear as tufts on the surface.

To inspect, hold the webbing with your hands six to

eight inches apart. Bend the webbing in an inverted

U to cause surface tension, exposing problem areas.

Inspect all web areas. Damage from cuts, abrasion,

corrosives, heat or chemicals should be apparent.

2. Buckle and belt ends.

Inspect the ends of all straps. They are subject to

wear as a result of repeated opening and closing.

Enlargement or distortion of holes may indicate

excessive wear or possible damage through impact

loading. Harnesses with unusually enlarged or

distorted holes should fail inspection.

3. D-Rings.

All D-Rings should be checked for distortion. D-ring

attachment points should be checked for unusual

wear or damaged Fibers. Badly pitted D-rings indicate

chemical corrosion, and the equipment should

fail inspection.

4. Stitching or rivets at hardware attachment points.

For stitched attachment points, check that stitching

is not broken, burned, cut or pulled. Check all riveted

attachment points for tightness. Badly pitted rivets

indicate chemical corrosion, and the equipment

should fail inspection.

5. Tongue buckles.

All tongue buckles should be checked for distortion,

sharp edges and cracks. The tongue should move

freely and overlap the frame. Rollers should not be

distorted and should roll freely.

6. Friction slide adjusters.

Friction slide adjusters should be checked for sharp

edges, distortion. Make sure that the outer bars and

center bars are straight. Also check corners and

attachment points for wear and cracks.

7. Easy-connect buckle.

Easy-connect buckle (square rings) should be checked

for distortion, sharp edges and cracks. For stitched

attachment points, check that stitching is not broken,

burned, cut or pulled.

8. Friction style buckle.

Friction style buckles should be checked for sharp

edges, cracks and distortion. Make sure outer bars

and center bar are straight. Also check corners

and attachment points for wear.

9. Leather.

Leather should be soft and supple. Visually check

leather for cracks tears, burns, brittleness or other

signs of damage age or abuse. While the leather

components of the system are not load bearing,

damage to the leather is a sign that the entire harness

MAY NOT be in acceptable condition. Re-inspect

entire system. Leather should both look and feel good.

1O. Destroy or replace worn or damaged Harnesses.

If evidence of excessive wear, deterioration or

mechanical malefaction is observed; the harness

should be destroyed. Never work with worn or

damaged equipment. Using damaged or worn

equipment can cause serious injury or death.

11. The inspector is the most important part

of any inspection procedure.

Check all equipment thoroughly and follow all safety

procedures and guidelines. Don't take any shortcuts.

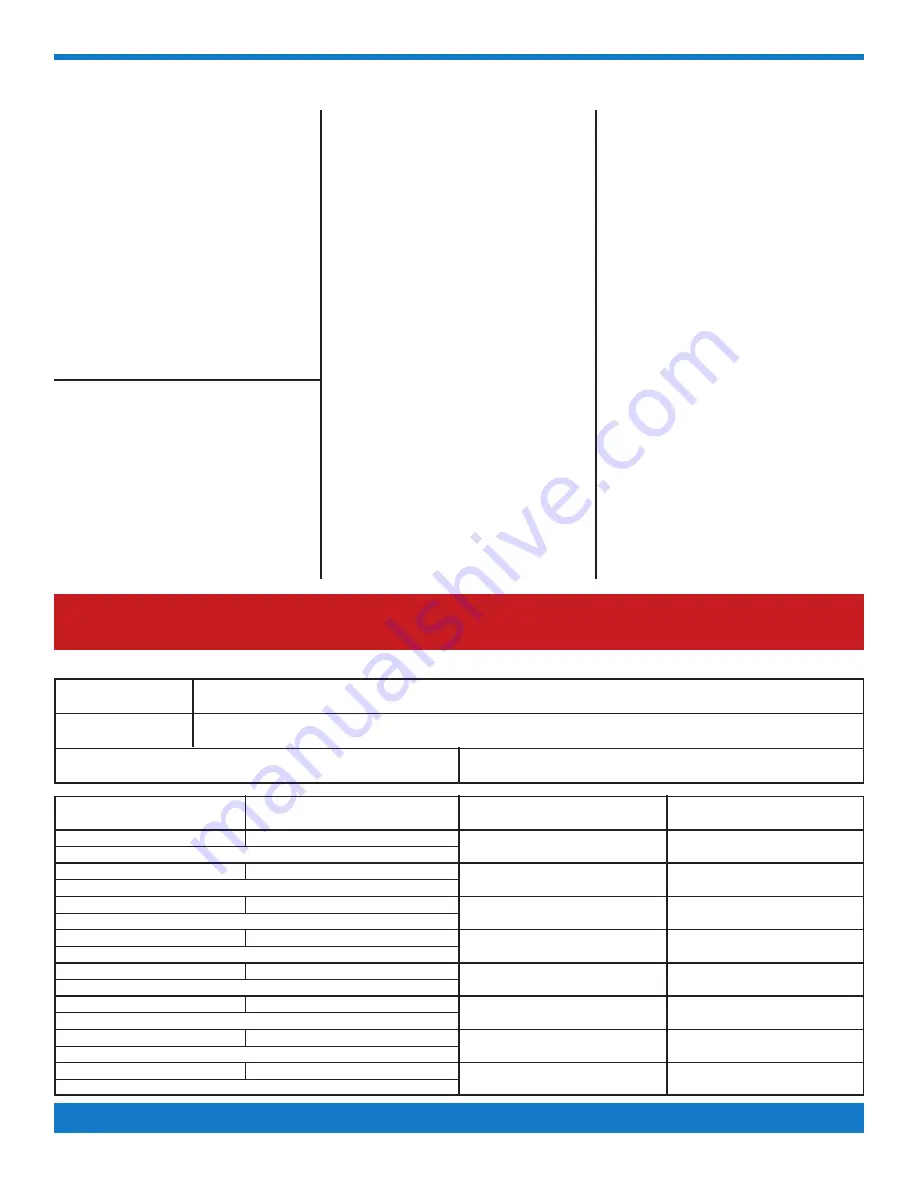

Harness System Inspection Procedures

Serial Number:

Model Number:

Date Purchased:

Inspection Date

Inspection Items Noted

Corrective Action

Maintenance Performed

Date of First Use:

INSPECTION AND MAINTENANCE LOG

IMPORTANT NOTE:

OSHA specifies that all employers covered by the Occupational Safety and Health Act are responsible for inspection and

maintenance of all tools and equipment used by employees, whether owned by the employees or by the company. All Ultra-Safe equipment

should be inspected before each use, and immediately removed from service if equipment does not pass inspection.

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By: