2

BEFORE EACH USE:

Inspect all your personal fall protection

equipment before each use. OSHA 1910.66 and

1926.502 and ANSI Z359.14 Class B (SLE)

requires an inspection before each use. The

use of American National Standards is

completely voluntary. Their existence does not,

in any respect, preclude anyone. ANSI requires

a formal documented inspection of fall

protection equipment to be completed by a

competent person other than the user, at a

minimum of once a year. More frequent

inspections by a competent person may be

required based on the severity of the

workplace conditions.

ULTRA-SAFE equipment is designed for use

with only ULTRA-SAFE approved components

and ULTRA-SAFE sub systems. Substitutions

or replacements made with non-approved

components or subsystems may jeopardize

compatibility of equipment and may affect the

safety and reliability of a complete system.

Personal fall arrest systems must meet

applicable local, state, and federal OSHA

requirements. Connectors (hooks. Carabiners.

and D-Rings) must be capable of supporting at

least 5000 Ibs. Do not use equipment that is not

compatible with the anchorage or other

system components. Connectors must be

compatible in size, shape, and strength. Self

locking snap hooks and carabiners are required

by ANSI Z359.14 Class B (SLE) and OSHA.

NOTE:

Large throat opening snap hooks

should not be connected to standard size D-

Rings or similar objects which will result in a

load on the gate if the hook or D-Ring rotates

or twist. Large throat snap hooks are designed

for use on fixed structural elements such as

cross members or rebar that are not shaped in

a way that can capture the gate of the hook.

FALL:

After a fall, equipment which has been

subjected to fall arrest forces MUST be

removed from service for inspection. Inspect

the entire safety retractable lanyard such as the

load / impact indicator. On web style find the

fold on the web to see if the stitching is broken

and the fold torn apart or for wire style check

the swivel snap hook to see if the RED indicator

was engaged. The safety retractable lanyard

must be removed from service and returned to

an authorized service station for repair, do not

re-stitch or repair..

ULTRA-SAFE

®

SAFETY RETRACTABLE DEVICE INSPECTION CRITERIA: The authorized person using this equipment shall, at a minimum comply with manufacturer’s

instructions regarding the inspection, maintenance, and removal from service of the equipment. Equipment shall be inspected by the authorized person before each use.

Additionally, inspections shall be conducted by a competent person other than the user. Inspection criteria for the equipment shall be set by the safety program administrator.

Documentation of equipment inspection shall be maintained by the safety program administrator. Inspections shall be conducted in intervals based on the type of use,

infrequent, moderate, and severe. If inspections reveal defects, damage, stress, activated warning systems or inadequate maintenance, the equipment shall be permanently

removed from service or undergo corrective maintenance through the manufactures authorized service department

.

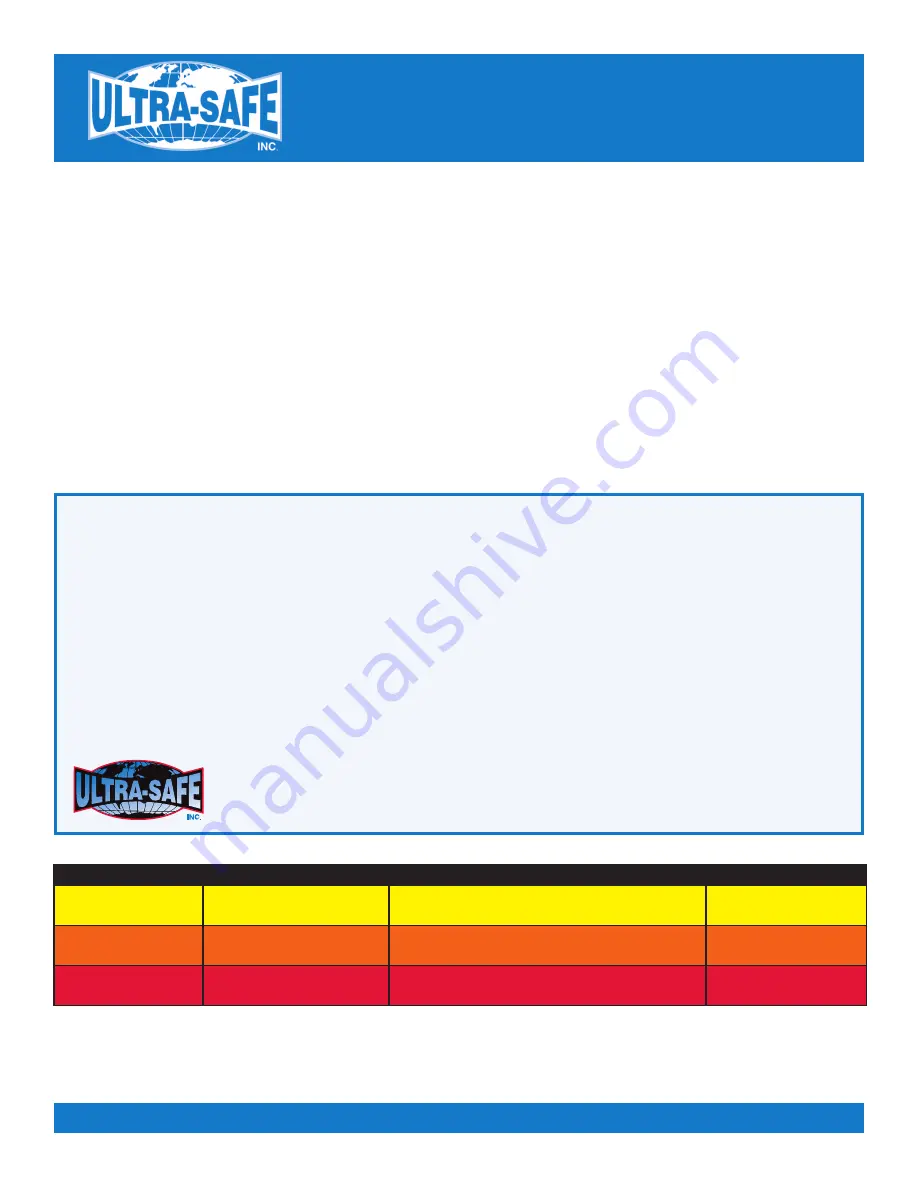

Type of Use:

Application Example:

Conditions of Use:

Inspection Frequency:

Infrequent to Light

Rescue and confined space,

factory maintenance

Good storage conditions, indoor or infrequent outdoor

use, room temperature, clean environments

Annually

Moderate to Heavy

Transportation, residential

construction, utilities, warehouse

Fair storage conditions, indoor and extended outdoor

use, all temperatures, clean or dusty environments

Semi-annually to annually

Severe to Continuous

Commercial construction,

oil and gas mining

Harsh storage conditions, prolonged or continuous

outdoor use, all temperatures, dirty environment

Quarterly to semi-annually

Inspection Requirements (normative)

I acknowledge that I have read

and understood the competent

inspection section completely

and agree to abide by them.

COMPETENT INSPECTION:

1. Ensure the safety retractable locks when

the lifeline is pulled sharply, with no

slippage. Lock-up should be positive.

2. Labels must be present and fully legible.

3. Check the connecting hooks or carabiners

for damage, distortion, or corrosion, and

working condition.

4. Check the housing for distortion, cracks, or

other damage and make sure anchorage

point is not distorted or damaged.

5. Inspect each component of the personal

fall protection system according to the

manufacturers instructions.

6. The lifeline must fully extend and retract

smoothly with no hesitation or slack on

the line.

7. Check the lifeline for cuts, burns, chemical

damage, abrasions, loose strands, or

corrosion, the lifeline must not be

damaged.

8. Check for loose or missing screws and

bent or damaged parts.

9. Use of this equipment in areas where

surrounding hazards exist may require

additional precautions to reduce the

possibility of injury to the user or damage

to the equipment. Hazards may include,

but are not limited to: high heat, caustic

chemicals, corrosive environments, high

voltage power lines, explosive or toxic

gases, moving machinery, or overhead

materials that may fall and contact the

user or fall arrest system.

10.

CAUTION -

This unit has an internal

shock absorbing system. Do not attach

external shock absorber to either end of

retractable. Doing so may cause the

brake pull to disengage increasing

freefall.

11. Do not use standard web retractables in

temperatures over 122ª degrees F

12. A competent inspection is required at

least one time per year.

Name (Print) ____________________________ Date _______________

Signature __________________________________________________