Ver. 01NL okt19

15

MAKERS LAB

Benno Premselahuis

Rhijnspoorplein 1

1091 GC Amsterdam

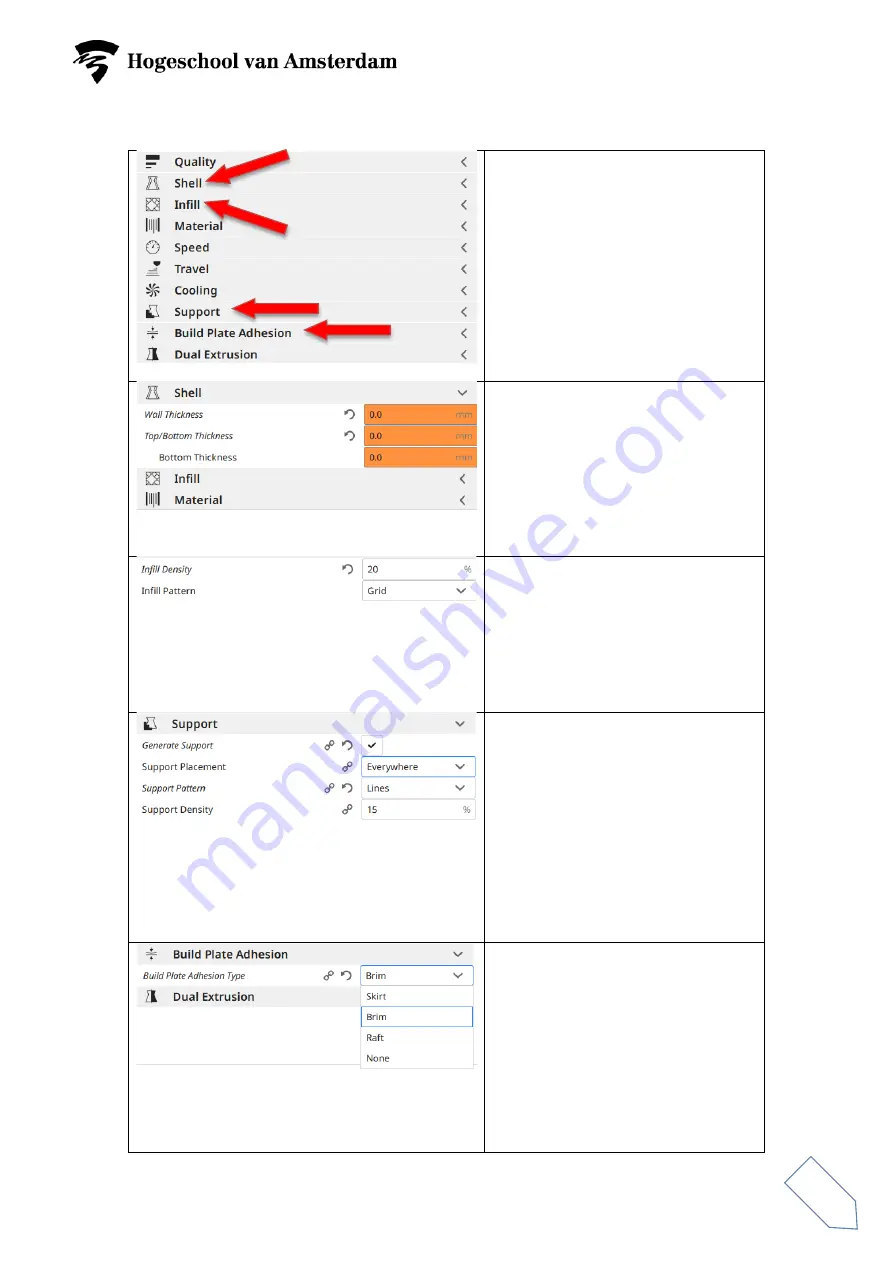

Custom

menu

There is no standard setting for

printing complex models.

Experimenting is recommended.

Always try to use as little support

material as possible in order to be

able to remove it easily, leaving as

few ‘scars’ as possible on the

model.

The

‘Shell’

menu is used to set the

thickness of the walls, bottom and

top. Things to consider regarding

settings:

•

Strength of the product

•

Costs

•

Printing time

The

‘Infill’

menu is used to set the

density and the filling pattern.

Things to consider regarding

settings:

•

Strength of the product

•

Costs

•

Printing time

The

‘Support’

menu is used to set

the pattern and density of the

support material. The

recommended

Support Pattern

is

‘Lines’

.

Things to consider regarding

settings:

•

Easy removal of support

material

•

Support scarring left on

product

The

‘Build Plate Adhesion’

menu is

used to set the adhesion of the

model to the glass plate.

Build Plate Adhesion Type

standard

=

Brim

or

None

.

A number of matters depend on the

dimensions and shape of the

footprint on the glass plate.