10

www.beer-co.com

ZEUS

Согласно требований

EN 378-1-

2014, для витрин холодильных, работающих на воспламеняемом хла-

дагенте (например,

R

290), регламентируется минимальный объём помещений для размещения

исходя

из нижнего концентрационного предела воспламеняемости. Так для витрины, работающей на хлада-

генте

R

290, минимальный объём помещения, в котором она может быть размещена, составляет 12,5 м

3

на каждые 100 гр

.

заправленного хладагента. В случае размещения в одной комнате нескольких витрин,

работающих на воспламеняемом хладагенте, величины их заправок

суммируются и объём помещения

должен подбираться соответственно их суммарной заправке (величины заправок указаны на шильди-

ках).

В

случае не соблюдения правил установки витрины, эксплуатационные характеристики

могут не соответ-

ствовать заявленным.

6.

УСЛОВИЯ

ЭКСПЛУАТАЦИИ

Витрина холодильная

предназначена для эксплуатации внутри помещения

с температурой окружающего

воздуха в пределах от +12ºС до +25ºС при

относительной влажности

не более 60%, что

соответствует

требованиям

эксплуатации согласно

климатическому классу 3 (табл.2

Климатические классы окружающей среды согласно

UNI

EN ISO 23953 - 2

.

).

Таблица 2 -

Климатические

классы окружающей среды

Климатический класс

Температура сухого тер-

мометра °С

Относительная влаж-

ность %

Температура испарения

°С

0

20

50

9,3

1

16

80

12,6

8

24

55

14,4

2

22

65

15,2

3

25

60

16,7

4

30

55

20,0

6

27

70

21,1

5

40

40

23,9

7

35

75

30

7.ПОДКЛЮЧЕНИЕ

Работы по монтажу витрины и ее подключению к электросети должны выполняться только квалифици-

рованным персоналом в соответствии с действующими нормами безопасности

.

Подключение витрины к электросети производится только через розетку совместимую с вилкой витрины

.

Электрическая схема витрины отображена в приложении А.

Заземление витрины через бонку заземления должны производить квалифицированные специалисты. Не до-

пускается использовать в качестве контура заземления трубы отопительной и водоснабжающей системы, а также

газопровода.

ВНИМАНИЕ!

Для подключения витрины к электропитанию необходимо использовать розетку пере-

менного тока, номинальным напряжением и частотой согласно региональному стандарту промышленной

электросети

.

Summary of Contents for ZEUS

Page 1: ......

Page 4: ...4 www beer co com ZEUS...

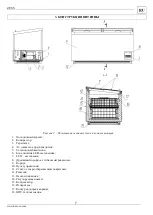

Page 6: ...6 www beer co com ZEUS 1 1 2 3 4 QR 5 QR 6 QR 7 8 ISO 9 10 11 12 13 14 IP 15 16 17 18 19 20 21...

Page 7: ...www beer co com 7 ZEUS 3 2 1 2 3 4 5 6 LED 7 LED 8 9 10 11 12 13 14 15 16 17 18...

Page 8: ...8 www beer co com ZEUS 4 IEC 60529 2013 IEC 61140 2012 80 100...

Page 9: ...www beer co com 9 ZEUS 5 3 3 0 2 15 UL 471 18 450...

Page 11: ...www beer co com 11 ZEUS 4 10 10 4 8 4 6 2 10 1 5 2 1...

Page 13: ...www beer co com 13 ZEUS 4 12 3 3 3...

Page 14: ...14 www beer co com ZEUS 13...

Page 15: ...www beer co com 15 ZEUS 14 4 4 6...

Page 16: ...16 www beer co com ZEUS 15 3 16 25 55 80 17 www beer co com...

Page 19: ...www beer co com 19 ZEUS...

Page 22: ...22 www beer co com ZEUS 3 2 1 2 3 4 5 6 LED 7 LED 8 9 10 11 12 13 14 15 16 17 18...

Page 23: ...www beer co com 23 ZEUS 4 IEC 60529 2013 IEC 61140 2012 80 100...

Page 24: ...24 www beer co com ZEUS 5 3 3 0 2 15 UL 471 18 450...

Page 26: ...26 www beer co com ZEUS 4 10 10 4 8 4 6 2 10 1 5 2 1...

Page 28: ...28 www beer co com ZEUS 2 12 3 3 3...

Page 29: ...www beer co com 29 ZEUS 13...

Page 30: ...30 www beer co com ZEUS 14 4 4 6...

Page 31: ...www beer co com 31 ZEUS 15 3 16 25 55 80 17 www beer co com...

Page 52: ...52 www beer co com Annex D Coupling of the refrigerated display cabi nets...

Page 53: ...www beer co com 53 For notes...

Page 55: ...www beer co com 55...