6

revised 09/09

Smog-Hog

SG Series Model

4.6 POWER PACK

input to the high voltage power pack range from 90 to

130 Vac, 60 Hertz. this is supplied by the power line

or the step-down transformer as shown by the wiring

diagram inside the junction box.

4.7 AIR DIFFUSER

the adjustable air diffuser outlet grille can be set to any

desired open position.

unducted installation (for area capture): air dif fuser

should be set for maximum contaminant capture and

even dispersion of clean air. the pattern should be

that suggested by uaS or your local SMoG-HoG

representative.

Ducted installation (for direct capture): air diffuser can

be set to any position that is compatible with personnel

comfort.

5. START UP AND OPERATION

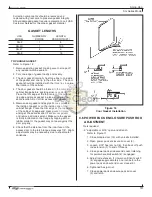

5.1 INSTALLING COMPONENTS

if unicells and filter media were removed for shipment

or installation, refer to figure 20 for proper installation

and electrical contact alignment. filter media is

installed as after filters (after the unicell) with optional

in-Place cleaning. Do not install filter media as pre-

filters (before the unicell) with in-Place cleaning.

this will reduce the effectiveness of the wash cycle

by 50 percent. the filter media is utilized as pre- and

after-filters if the SG is not equipped with In Place

cleaning. the SG inlet plenum, if supplied by uaS,

could have filter media or impingement filters. the inlet

plenum should be inspected that all filters are installed.

5.2 BLOWER ROTATION

for proper airflow, the blower should be operating in

the correct direction. if the blower is operating in the

reverse direction, air will move in the proper direction,

but at significantly reduced rates.

to check rotation:

1. Place SG unit off line.

2. remove or open blower panel from SG unit to

observe rotation.

3. Place SG unit on line for less than one minute.

4. Place SG unit off line.

5. as the blower pulley slows down, observe the

direction of rotation.

6. note directional arrow located on the blower

housing.

Extreme care should be exercised when operating

blowers with motor/drive belts exposed. Loose

fitting clothing can easily be drawn into these

moving parts.

7. if blower wheel was not rotating in the correct

direction, disengage main three-phase fused

disconnect switch.

Do not attempt to rewire electrical “live”

connections.

8. open power panel and reverse any two of the

three wires at the terminal strip (Ll, L2, and L3).

9. engage the fused disconnect and place SG unit

on line, confirming blower rotation.

!

WARNING

!

WARNING

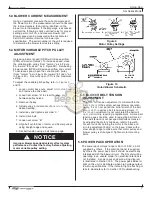

Figure 7

Blower Units Without In-Place Cleaning

Figure 8

Blower Units With In-Place Cleaning