SKU 02575

For technical questions, please call 1-800-444-3353.

Page 9

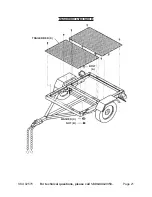

Align the

3.

two

mounting holes in a Rear Spring Hanger (15R) with the

two

mounting

holes located in the rear section of the Left Side Rail (1L). Insert

two

3/8” x 7/8”

Carriage Bolts (A)

upward from the underside

of the aligned mounting holes, and

secure the Rear Spring Hanger to the Left Side Rail with

two

Washers (C) and

two

Nuts (B).

Align the

4.

two

mounting holes in the remaining Rear Spring Hanger (15R) with the

two

mounting holes located in the rear section of the Right Side Rail (1L). Insert

two

3/8” x 7/8” Carriage Bolts (A)

upward from the underside

of the aligned mounting

holes, and secure the Rear Spring Hanger to the Right Side Rail with

two

Washers

(C) and

two

Nuts (B).

Align the mounting hole on the end of a Spring (18) with the mounting hole located

5.

on the side of one of the

pre-attached

Front Spring Hangers (15F), and secure the

Spring to the Front Spring Hanger with

one

Bolt (N) and

one

Nut (B).

Insert the second Spring Bolt (N) underneath the curved edge at the rear of the

6.

Spring (18) and through the mount hole of the Rear Spring Hanger (15R). Secure

with one Nut (E).

For the remaining Spring (18), Front Spring Hanger (15F), and Rear Spring Hanger

7.

(15R), repeat Steps #5 and #6.

Align the center mounting hole of a Spring Plate (16) with the center mounting hole

8.

of a

pre-attached

Spring (18), and secure the Spring Plate to the Spring with two U

Bolts and Nuts (U Bolts fit underneath the axles with threaded ends up). Repeat

this step on opposite side of Trailer.

Align the center mounting hole of the remaining Spring Plate (16) with the center

9.

mounting hole of the remaining

pre-attached

Spring (18), and secure the Spring

Plate to the Spring with

one

Bolt (A),

one

Washer (C), and

one

Nut (B).

With assistance, position the

10.

pre-assembled

Tire, Wheel, and Axle Assembly under

the mid-section of the

pre-assembled

Frame of the Trailer.

On the right side of the Trailer, insert

11.

two

U-Bolts (17) upward, over the right end of

the Axle (19), and through the

four

mounting holes in the Spring Plate (16). Then,

secure the right end of the Axle to the Spring (18) by tightening

four

Washers (C)

and

four

Nuts (B) onto the two U-Bolts.

On the left side of the Trailer, insert the remaining

12.

two

U-Bolts (17) upward, over the

left end of the Axle (19), and through the

four

mounting holes in the Spring Plate

(16). Then, secure the left end of the Axle to the Spring (18) by tightening

four

Washers (C) and

four

Nuts (B) onto the

two

U-Bolts.

REV 05/03