PAGE 6 OF 18

0518 IH-6323

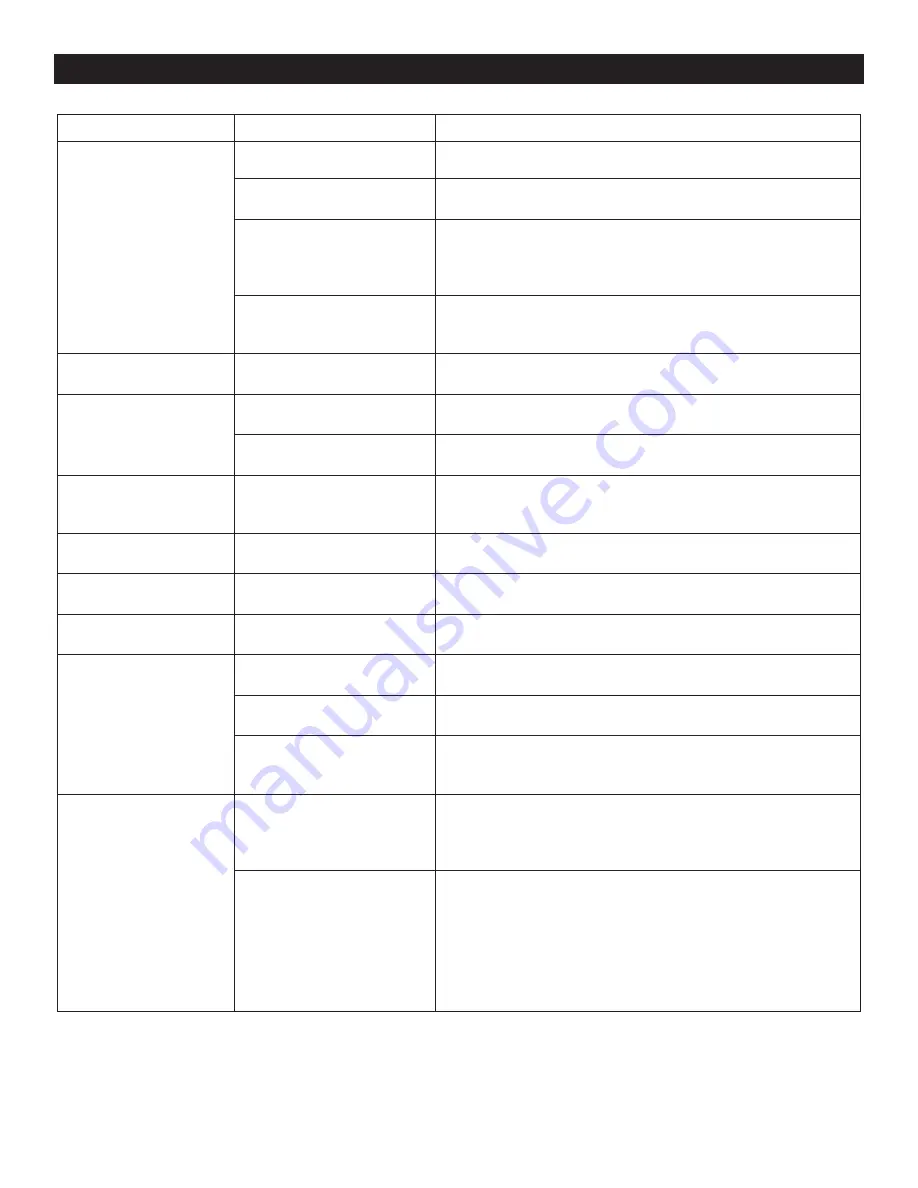

ISSUE

POSSIBLE CAUSE

RESOLUTION

General print quality

issues - the printed

image does not look

right.

The printhead is dirty.

Clean the printhead. See Cleaning the Printer.

You may be using the

wrong power supply.

Verify you are using the power supply that came with this

printer.

The printhead has worn out.

Replace the printhead. The printhead is a consumable item

and will wear over time due to friction between the media

and printhead. Using unapproved media may shorten

printhead life or damage your printhead.

The platen (drive) roller

may need cleaning or

replacement.

Clean or replace the platen (drive) roller.

No print on the label.

Media has been loaded

incorrectly.

The media printable surface must face up towards the

printhead. Follow the instructions for Loading Media Roll.

Loss of printing

registration on labels.

Excessive vertical drift in

top-of-form registration.

The platen (drive) roller is

dirty.

Clean the printhead and platen roller. See Cleaning the

Printer.

The media is loaded

incorrectly.

Load media correctly. See Loading Media Roll.

Printing too light or too

dark over the entire

label.

The media or ribbon is not

designed for high-speed

operation.

Replace supplies with those recommended for high-speed

operation.

Smudge marks on

labels.

Improper label format.

Check your label format and correct it as necessary.

Mis-registration/skips

labels.

Improper label format.

Check your label format and correct it as necessary.

Vertical drift in top-of-

form position.

The platen (drive) roller is

dirty.

Clean the printhead and platen roller. See Cleaning the

Printer.

Vertical image or label

drift

The platen (drive) roller is

dirty.

Clean the printhead and platen roller. See Cleaning the

Printer.

The media is loaded

incorrectly.

Ensure that the media is loaded correctly. See Loading

Media Roll and Printing a Test Label.

Incompatible media.

You must use media that meets the printer specifications.

Ensure that the inter-label gaps or notches are 3 to 4 mm

and consistently placed.

The barcode printed on

a label does not scan.

There is not enough

blank space around the

barcode.

Leave at least 1/8 in. of blank space around the barcode

(referred to as the quiet zone) and other printed areas on

the label and between the barcode and the edge of the

label. This requirement varies by barcode type.

There is a void or missing

print in a barcode, text or

graphic in a printed form.

Voids can look like a white

bar area in a barcode.

Perform Cleaning the Printer to remove contaminants on the

printheads. Reprint and test the barcode.

Use the Printer and Network Configuration Reports from

Cleaning the Printer to see if the printhead has damaged

printhead elements. Verify that the large black bar on the

bottom of the printed test label does not have any streaks

or voids after thoroughly cleaning the printhead.

TROUBLESHOOTING

π

CHICAGO • ATLANTA • DALLAS • LOS ANGELES • MINNEAPOLIS • NYC/PHILA • SEATTLE • MEXICO • CANADA

1-800-295-5510

uline.com