1013 IH-2034

PAGE 2 OF 5

GENERAL

1. H-2034 Shrink Tunnel consists of a tunnel and a

conveyor. The conveyor is a teflon coated mesh belt.

The mesh belt allows the heated air to shrink the

bottom of the package from the tunnel.

2. There are two control panels for the operation of

the machine. The lower panel controls the conveyor

and the upper panel controls the tunnel.

MACHINE STARTUP

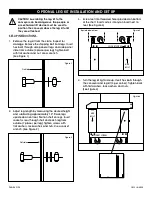

1. Turn on the conveyor using the ON/OFF rocker switch.

The ON/OFF switch will light up. Set the conveyor

speed to "2" on the operator panel. (See Figure 1)

2. If the power light is not on, plug in the tunnel.

3. Turn on the tunnel using the ON/OFF switch.

4. Set the tunnel temperature to a setting of 325º F

on the tunnel’s operator panel. It will take 20 - 30

minutes to reach temperature. The heat indicator

light will go off when it has reached temperature.

(See Figure 2)

5. After the initial package has been run through the heat

shrink tunnel, the following adjustments may be made:

a. Increase or decrease the thermostat setting.

b. Increase or decrease the conveyor speed.

c. Increase or decrease the temperature if

available.

6. Due to the various types of shrinkable films, room

temperatures and voltages, you may have to

experiment with various temperatures and conveyor

speeds, to get the desired shrink. Your film supplier

is familiar with this type of equipment and will be

helpful in determining the best settings for the film

you are using.

ON/OFF

OFF 550

500

450

400

350

300

250

200

THERMOSTAT

HEAT INDICATOR LIGHT

POWER LIGHT

Figure 1

INSTRUCTIONS

RESET

OFF

MAIN

POWER

CONVEYOR

SPEED

CONVEYOR

TEMP

820HB ONLY

ON/OFF SWITCH

CIRCUIT BREAKER

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

Figure 2

The machine should be inspected on a timely basis to

ensure all is functioning well and in good working order.

There is not much required to keep the machine running

trouble free. The most important area is the seal head.

The following are recommendations for preventative

maintenance on the machine to keep it performing well

over an extended period.

MAINTENANCE TIPS

1. Inspect the conveyor belts for wear and

misalignment. If the belts are not tracking properly,

adjust the idler rollers to realign the belts. Replace

worn belts as needed.

2. Lubricate all chain drives every 160 hours of

operation with a bearing grease or chain lubricant.

3. To clean the machine, wipe down the conveyor

belts and other flat surfaces to remove any dirt. Do

not use any type of belt dressing on the conveyor

belts.

MAINTENANCE