2. Adjusting rotating hook point timing with

needle.

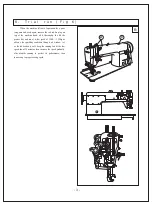

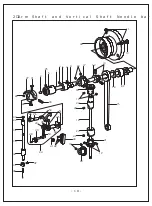

The motive relation between rotating rotating

and needle affects the sewing quality. Standard tim-

ing relation is : turn the balance wheel to locate

needle bar to its lowest position , and lift back

2.5 mm the rotating hook point(D) should be coin-

cides with needle center line ( C ),and hook point

( D ) is 1.2mm above the upper edge(E)of needle eye.

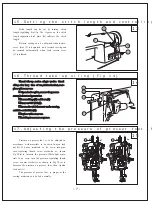

When adjusting the rotating hook point tim-

ing also to note the clearance between notch bot-

tom of needle (D) and hook point ( C ) of approx

0.05mm must be maintained. (Fig 26)

.

.

.

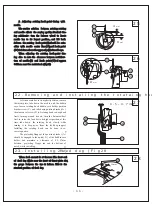

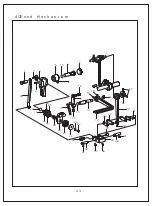

Lift the needle bar to its highest position, remove

the throat plate, take down the needle and the bobbin

case. loosen rotating hook bobbin case holder position

bracket screw( C ) and take down position bracket( A ),

then loosen set screw.( D )of rotating hook to keep hook

freely, turning around its axis, turn the balance wheel

first to raise the feed bar to its highest position, at this

time, take down the rotating hook slowly while

turning it to keep away from the feed dog support.

Installing the rotating hook can be done in re-

verse sequence.

The projecting flange of the position bracket ( A )

should be engaged in the notch( B ) of the bobbin case

holder, and maintain a clearance of 0.5~0.7mm

between projecting flange top and the bottom of

notch while installing.

.

.

22.Removing and installing the rotataing hook(Fig 27)

28

-11-

27

25

26

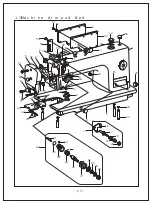

23.Installing feed dog (Fig28

、

29)

A

C

D

B

0.5-0.7mm

A

B

C

D

0.05

m m

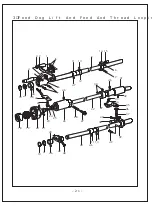

When feed amount is at the max. The front end

of feed dog (A) is near the front of throat plate slot,

the gauge between the two is 1.5mm. This is the

standard position of feed dog.

A

1.5mm

C

D

E

2.5

1.2

m m

m m