© Trynex International 2009 L1302

1 —55

Warranty Registration and Customer Survey

To initiate the warranty on your new TurfEx product and assure prompt warranty service, please complete the

following warranty registration and customer survey, sign and mail it back to the factory within 30 days of purchase.

1)

Date of Purchase:

2)

Name:

Address:

Phone:

:

r

e

b

m

u

N

l

a

i

r

e

S

:

d

e

s

a

h

c

r

u

P

l

e

d

o

M

Turfex

)

3

4)

Is this your first Turfex Product?

Yes

No

5)

What type of vehicle are you using with your Spreader, Broom and/or Sprayer?

r

a

e

Y

l

e

d

o

M

e

k

a

M

6)

What type of material are you using in your spreader and/or sprayer?

7)

TurfEx Dealer Name:

TurfEx Dealer Address:

Turfex Dealer Phone:

8)

Does your TurfEx Dealer stock Turf Ex replacement Parts?

Yes

No

I don’t know

9)

Do you feel your TurfEx Dealer sold you the correct product for your needs/application?

Yes

No

10) How would you rate

your overall satisfaction

with your Turfex Dealer?-

11) How would you rate

your overall satisfaction

with your Turfex Product?

12) Would you purchase another TurfEx Product?

13) If you would like to receive E-Mail ALERTS for new products, bulletins or special promotions please supply address : _________________________________________________

Yes

No

14) Please use the space below to convey your comments and/or suggestions.

NOTE:

I have read the owner’s manual and all safety precautions and I understand that this equipment could be dangerous if not operated

with care and under the proper conditions.

15) Owner’s signature:

X

Very

Satisfied

Very

Dissatisfied

Satisfied

Dissatisfied

Somewhat

Satisfied

Somewhat

Dissatisfied

Very

Satisfied

Very

Dissatisfied

Satisfied

Dissatisfied

Somewhat

Satisfied

Somewhat

Dissatisfied

PLEASE FOLD AND SEAL WITH TRANSPARENT TAPE BEFORE MAILING.

R

Summary of Contents for TS-1200-E

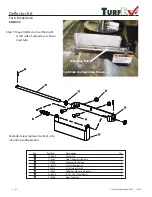

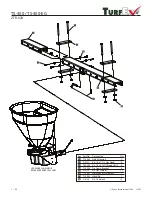

Page 8: ... Trynex International 2009 L1302 1 8 TS 300 Main Assembly Views R ...

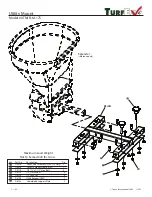

Page 14: ... Trynex International 2009 L1302 1 14 TS 300 EG Electric Gate Control System ...

Page 16: ... Trynex International 2009 L1302 1 16 TS 300 EG Gate Assembly Views R ...

Page 17: ... Trynex International 2009 L1302 1 17 TS 300 EG Front Rear Assembly Views R ...

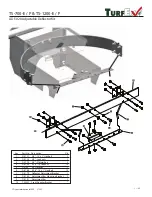

Page 28: ...TS 700 GR TS 1200 GR Main Frame Assembly Trynex International 2009 L1302 1 28 R ...

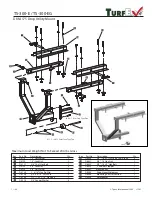

Page 30: ... Trynex International 2009 L1302 1 30 R TS 700 GR TS 1200 GR Drive Assembly ...

Page 34: ... Trynex International 2009 L1302 1 34 R THIS PAGE INTENTIONALY LEFT BLANK ...

Page 35: ... Trynex International 2009 L1302 1 35 R THIS PAGE INTENTIONALY LEFT BLANK ...

Page 40: ...R BLANKPAGE Blank Page Trynex International 2009 L1302 1 40 THIS PAGE INTENTIONALY LEFT BLANK ...

Page 41: ...R BLANKPAGE Blank Page Trynex International 2009 L1302 1 41 THIS PAGE INTENTIONALY LEFT BLANK ...