10

H. BRAKE SECTION

ASSEMBLY

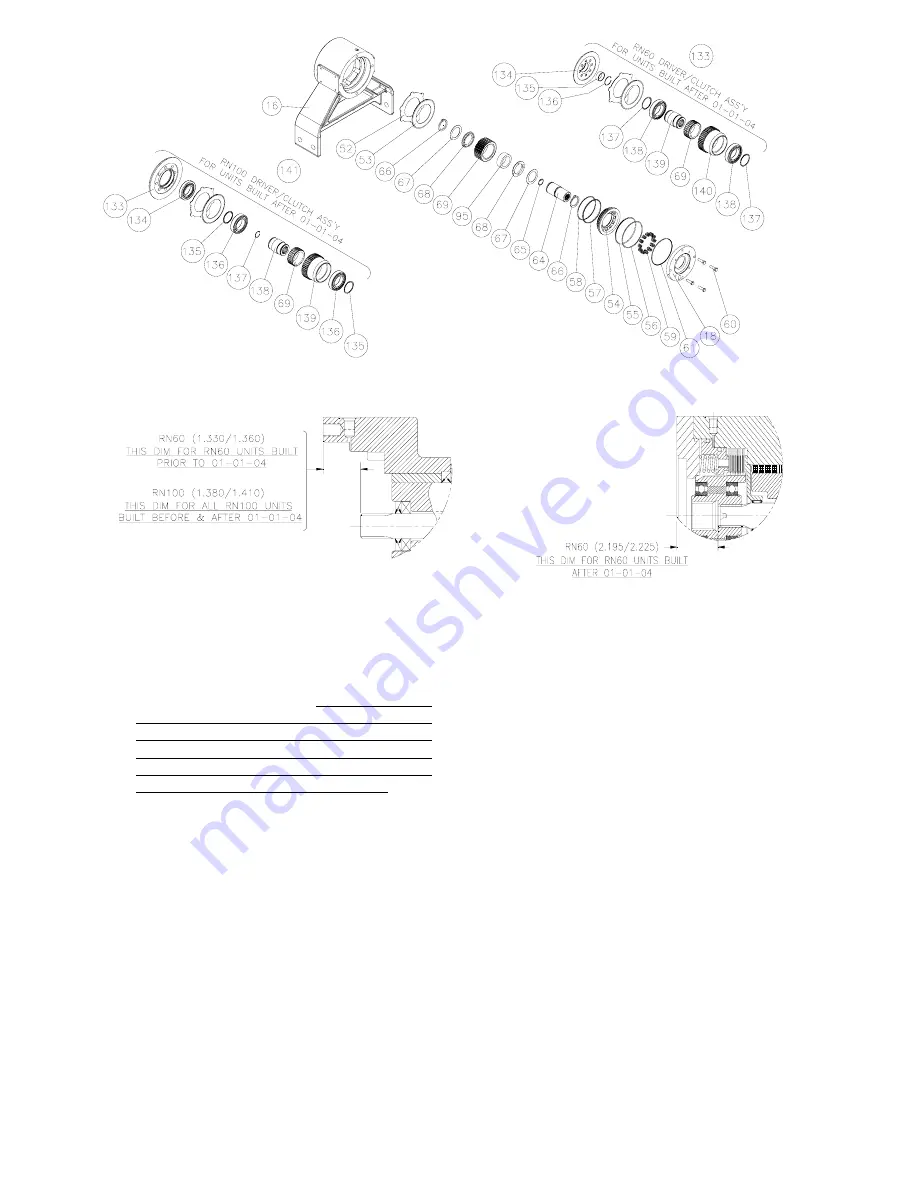

1. Measure the distance as shown above. If

needed add shims part number 33324 and

994188 inside input driver (64) to achieve

above noted dimension.

(Note: For RN60

units built after 01-01-04 measuring and

shimming is done after installing the cover (18)

as shown above. Refer to Field Service

Literature (FSL-0017) for RN45-130 product

enhancements to the driver/clutch ass’y

2. Re-assemble the driver/clutch assembly

making sure the clutch is installed properly

and checking to make sure the cam clutch is

free turning in the pay in direction. Install the

driver/clutch assembly onto input shaft (21A).

3. Install the stator plates (52) and friction discs

(53) starting with a stator plate and alternating

between friction discs and stator plates until

eight stator plates and seven friction discs are

used. Note: Soak friction discs in hydraulic oil

before installation

4. Coat the piston O.D. with oil or grease and

install the piston into the brake housing by

gently tapping it down until it is seated making

sure not to damage the o-rings or back-up

rings.

5. Install the springs into the spring pockets. If

working in a horizontal position, coat the

6. bottom of each spring with chassis lube to

keep it in position.

7. Coat the o-ring (61) with oil or grease and

install it into the groove on the brake cover

(18).

8. Install the cover onto the brake housing using

the capscrews (60). Then draw it down

evenly, alternating between opposite hex

bolts. Make sure that the cover is aligned

properly with the brake housing to orient the

motor as it should be.

9. Check the brake release with a portable

hydraulic pump. Full release should be

obtained at 340psi, plus or minus 20psi. Also,

check the brake for proper operation by

applying 280psi to the brake port and adapting

a torque wrench to the input shaft. The torque

in the payout should be 95 to 115 ft-lbs.

10. Install the motor (63) and secure with the four

capscrews (30). Tighten the capscrews to the

proper torque.

Note:

Make sure you install

the motor with the belly of it down and the

case drain port up.

Install the counterbalance

block. Hook up the brake line to the top of the

brake housing (16). Fill the brake and

gearbox with the proper oil.