Preventing reverse rotation of inclined or vertical conveyor systems is one of the most common applications for BACKSTOPS.

There are many configurations of conveyors systems that employ BACKSTOPS.

This paper presents the most common types and provides examples and calculations needed to properly size BACKSTOP in

order to maximize performance and improve safety of the conveying system.

*Suggested arrangement may not meet local design standards, please check local design standards.

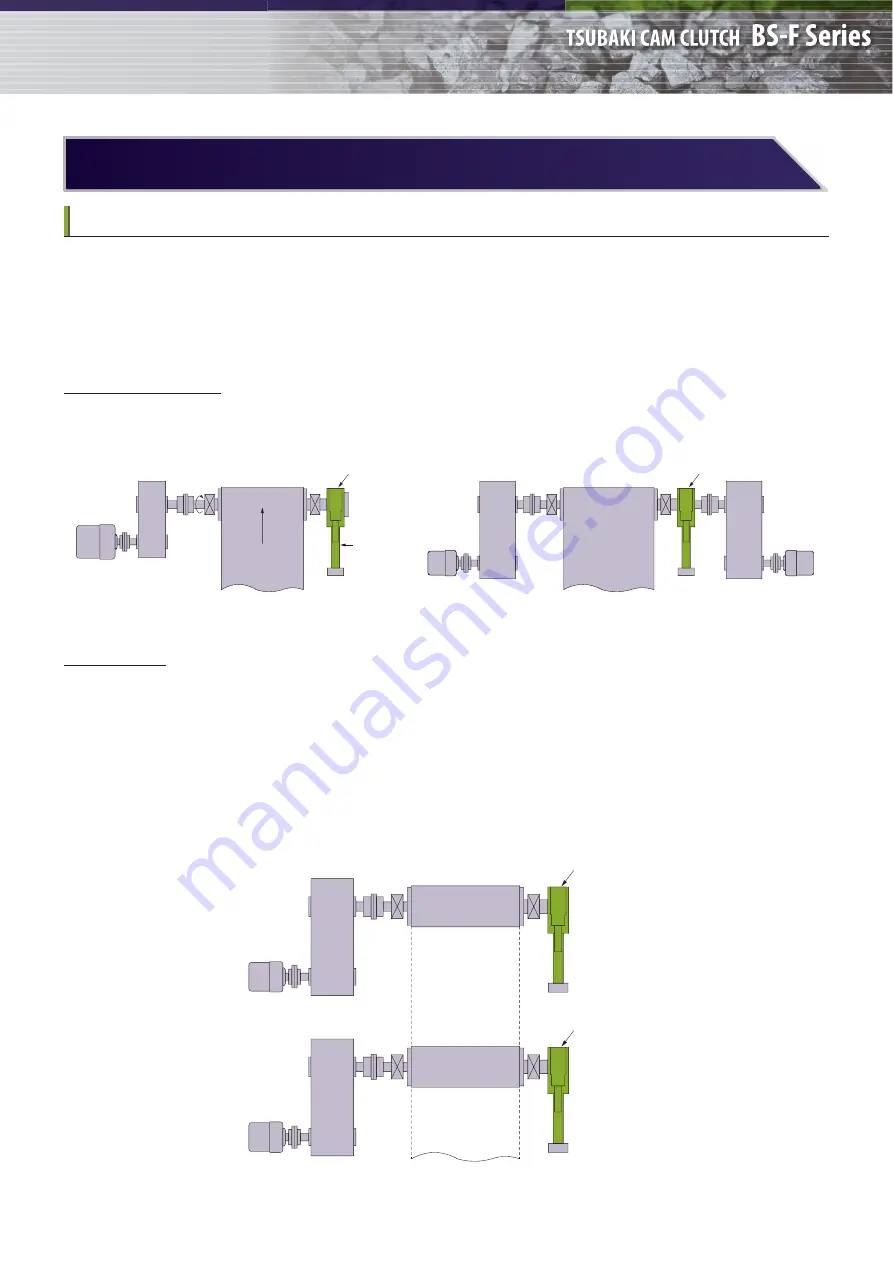

BACKSTOP Mounting Arrangements

Mounting arrangement

Figure 1

Figure 2

Figure 3

Single and Dual Drives

BACKSTOPS for low speed overrunning type are installed directly on the extended head shaft, as shown in Figure 1 and 2.

TSUBAKI recommends the single installation of the BACKSTOP to prevent the reverse rotation of head shaft.

Tandem Drives

When the conveyor arrangement calls for a primary and secondary drive, as shown in Figure 3, the BACKSTOP on the

primary drive unit holds the full load. The BACKSTOP on the secondary drive unit holds the back tension from the belt.

It keeps belt traction on both conveyor systems.

TSUBAKI recommends that the BACKSTOP, having the torque capacity equal to the sum of the primary and secondary

motors, be installed on the primary drive unit.

The BACKSTOP for secondary drive should be sized from secondary drive motor only.

*Suggested arrangement may not meet local design standards, please check local design standards.

Motor

Speed

Reducer

Belt Conveyor

BACKSTOP BS-F

Torque

Arm

Motor

Speed

Reducer

Belt Conveyor

BACKSTOP BS-F

Motor

Speed

Reducer

Motor

Speed Reducer

Belt Conveyor

BACKSTOP BS-F

P R I M A R Y

Motor

Speed Reducer

BACKSTOP BS-F

S E C O N D A R Y

4