Engine Operation

AT89373,0000002 -19-18AUG14-1/1

RK80614,0000009 -19-16OCT12-1/1

Break-In Service

Extra care during the first 100 hours of operation results in

satisfactory long-term engine performance and life. DO

NOT exceed 100 hours of operation with break-in oil.

1. This engine is factory-filled with John Deere Break-In

Plus™ oil. Operate the engine at heavy loads with

minimal idling during the break-in period.

2. If the engine has significant operating time at idle,

constant speeds, and/or light load usage, or additional

oil is required in the first 100 hour period, a longer

break-in period may be required. In these situations,

an additional 100 hour break-in period is recommended

using a new change of John Deere Engine Break-In

Plus Oil and a new John Deere oil filter.

3. Check oil more frequently during engine break-in

period. If oil must be added during this period, John

Deere Break-In Plus Oil is preferred. See John Deere

Break-In Plus™ Engine Oil — Interim Tier 4, Final Tier

4, Stage IIIB, and Stage IV in the Fuels, Lubricants,

and Coolants Section for other oils allowed.

IMPORTANT: DO NOT fill above the top of the

crosshatch pattern or the FULL mark, whichever

is present. Oil levels anywhere within

crosshatch are considered in the acceptable

operating range. John Deere Break-In Plus

engine oil should be used to make up any oil

consumed during the break-in period.

4. During the first 20 hours, avoid prolonged periods of

engine idling. If engine idles longer than 5 minutes,

stop engine.

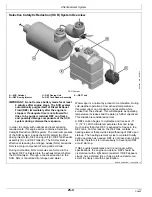

5. During the initial operation of a new or rebuilt engine

with Break-In Plus, change the oil and filter between

a minimum of 100 hours and a maximum of up to

500 hours (B). (Top-load oil filter illustrated.) (See

Changing Engine Oil and Replacing Filter in the

Lubrication & Maintenance — 500 Hours/12 Months

Section.) Fill crankcase with seasonal viscosity grade

oil. (See Diesel Engine Oil — Interim Tier 4, Final Tier

4, Stage IIIB, and Stage IV in the Fuels, Lubricants,

and Coolants Section.)

NOTE: Some increase in oil consumption may be

expected when low viscosity oils are used.

Check oil levels more frequently.

If temperature is below 0 °C (32 °F), it may

be necessary to use cold weather starting

aids (See Cold Weather Operation in the

Engine Operation Section).

If air temperature is below 0 °C (32 °F), use

an engine block heater.

6. Watch coolant temperature gauge closely during

engine operation. If coolant temperature rises

above 113 °C (235 °F), the engine reduces power

automatically. Unless temperature drops quickly, stop

the engine and determine the cause before resuming

operation.

Monitor oil pressure and coolant temperature to

ensure that they are within specification.

Specification

Engine —Oil Pressure at

Full Load Rated Speed.................................. 370 kPa (3.70 bar) (54 psi)

Minimum Oil Pressure at

Low Idle ........................................................ 150 kPa (1.50 bar) (22 psi)

Coolant Temperature

Range .............................................................. 85°–97 °C (185°–207 °F)

7. Check belt for proper seating in pulley grooves.

Break-In Plus is a trademark of Deere & Company

Generator Set (Standby) Applications

To assure that your engine will deliver efficient standby

generator operation when needed, start engine and run at

rated speed (with 50%—70% load) for 30 minutes every

2 weeks. DO NOT allow engine to run for an extended

period of time with no load.

Biodiesel fuel is not recommended for standby equipment

that can have minimal fuel consumption (such as standby

generators, fire protection, etc.). For standby applications,

use only petroleum based diesel fuel with John Deere

approved fuel conditioners and additives. For fuel

conditioners and additives, check with your local John

Deere dealer.

Petroleum diesel fuel should not be stored in service tanks

longer than two years even when using fuel additives.

See your fuel distributor or John Deere dealer for more

information.

20-1

032015

PN=50

Summary of Contents for PTV100/72

Page 11: ......

Page 12: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 44: ......

Page 54: ...Contents iv 032015 PN 4 ...

Page 175: ...Troubleshooting 70 35 032015 PN 133 ...

Page 187: ...Troubleshooting 70 47 032015 PN 145 ...

Page 205: ...Warranty DX EMISSIONS EPA 19 12DEC12 2 2 TS1721 UN 15JUL13 90 6 032015 PN 163 ...

Page 213: ...Warranty DX EMISSIONS CARB 19 01AUG14 8 8 RG26036 UN 24JUN14 90 14 032015 PN 171 ...

Page 214: ...Warranty 90 15 032015 PN 172 ...

Page 220: ...Engine Registration IBC 2 032015 PN 178 ...

Page 223: ...Engine Registration IBC 5 032015 PN 181 ...

Page 224: ...Engine Registration IBC 6 032015 PN 182 ...

Page 225: ...SERVICE MANUAL ...

Page 262: ...saue Axial Piston Pumps and Motors Service Manual Series 90 CONTENTS ...

Page 348: ...saue 87 Series 90 Exploded View Parts Drawings 10 Notes CONTENTS ...

Page 350: ......

Page 351: ......

Page 352: ......

Page 353: ......

Page 354: ......

Page 355: ......

Page 356: ......

Page 357: ......

Page 358: ......

Page 359: ......

Page 360: ......

Page 361: ......

Page 362: ......

Page 363: ......

Page 364: ......

Page 365: ......

Page 366: ......

Page 367: ......

Page 368: ......

Page 369: ......

Page 370: ......

Page 371: ......

Page 372: ......

Page 373: ......

Page 374: ......

Page 375: ......

Page 376: ......

Page 377: ......

Page 378: ......

Page 379: ......

Page 380: ......

Page 381: ......

Page 382: ......

Page 383: ......

Page 384: ......

Page 385: ......

Page 386: ......

Page 387: ......

Page 388: ......

Page 389: ......

Page 390: ......

Page 391: ......

Page 392: ......

Page 393: ......

Page 394: ......

Page 395: ......

Page 396: ......

Page 397: ......

Page 438: ......

Page 439: ......

Page 440: ......

Page 441: ......