20

4.1.3 Printer Initialization

Printer initialization sets printer parameters to default values. And it will not clear

downloaded files resident in flash memory.

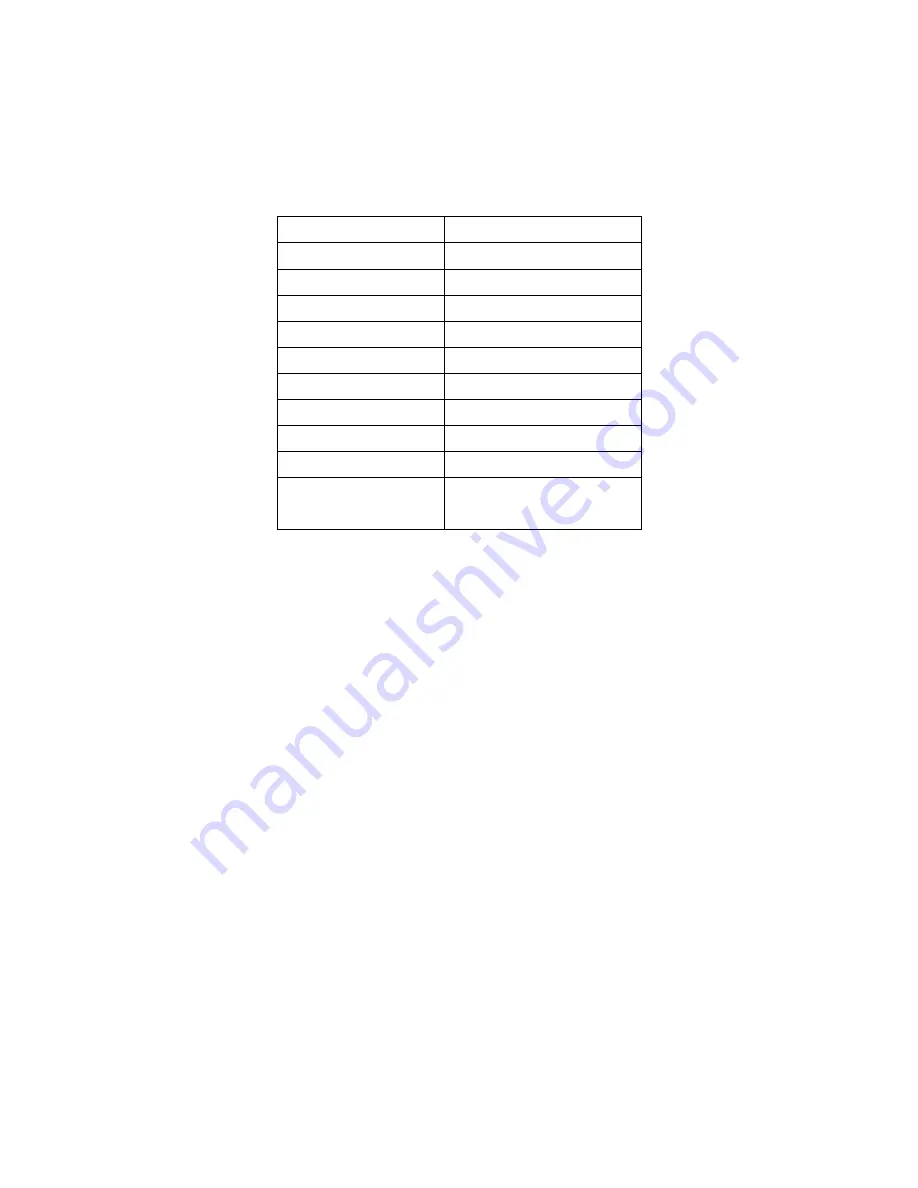

Parameter Default

Value

MILEAGE Automatic

CHECK SUM

Automatic

SERIAL PORT

9600,N,8,1

CODE PAGE

437 (8 bit)

COUNTRY CODE

001

SPEED 2.0”/sec

DENSITY 08

SIZE 4.26",

2.50"

GAP(BLINE) 0.12”,

0

TRANSPARANCY

Will be reset. Need to re-

calibrate the gap sensor

Please follow the steps below to initialize the printer:

1. Turn off the printer power.

2. Hold down the

PAUSE

and

FEED

buttons and turn on the printer power.

3. Do not release the buttons until the three LEDs flash in turn.

Note 1: Printing method (thermal transfer or thermal direct printing ) will be

set automatically at the activation of printer power.

Note 2: When printer initialization is done, sensor sensitivity is reset to

default. Sensor calibration is required before printing labels.

Note 3: Download files will not be deleted after printer initialization. For

more information about deleting files, please refer to TSPL2 programming

manual KILL command.