17

4. LED and Button Functions

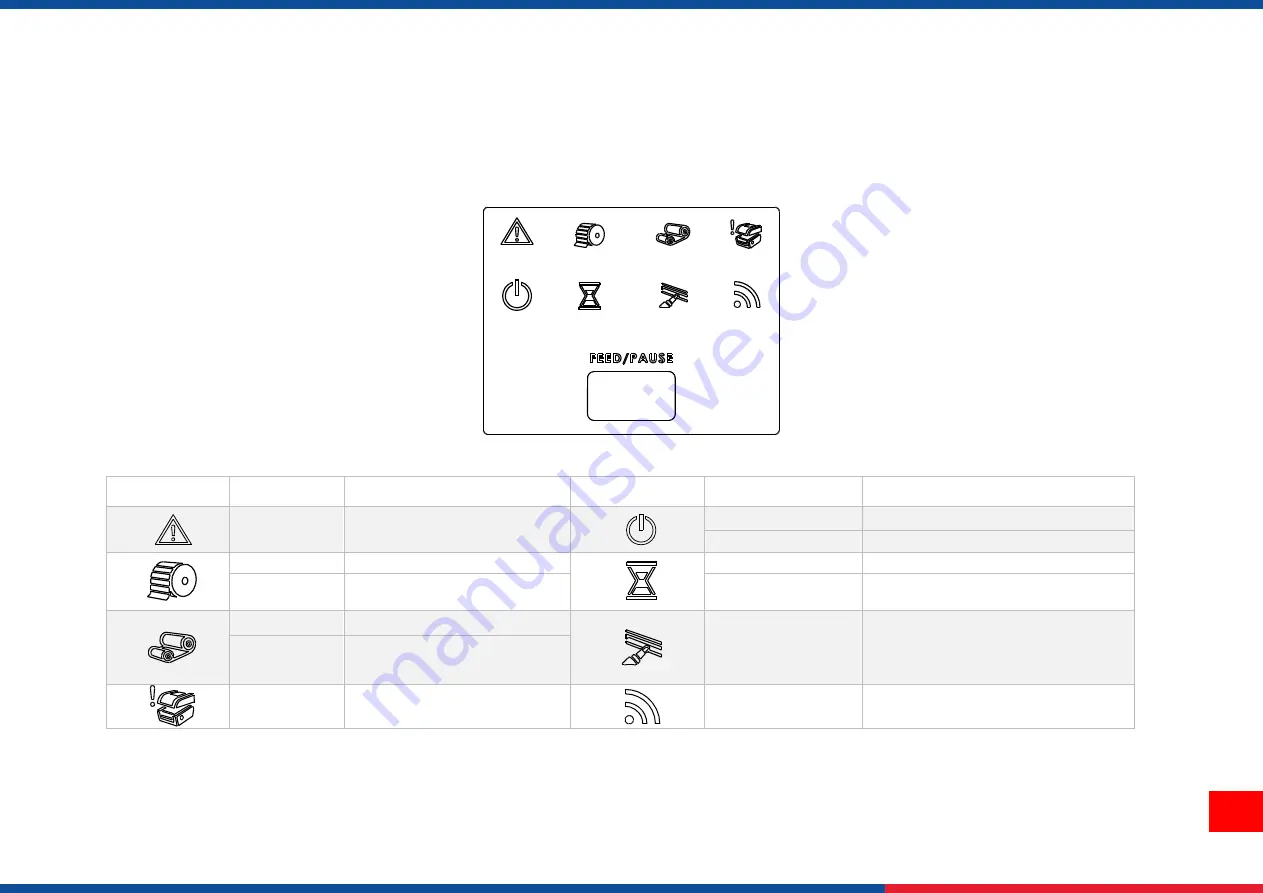

4.1 LED Indication and Key

LED

Status

Indication

LED

Status

Indication

On

Other errors

On

Printer is ready

Blinking

Pause

On

Out of paper

On

Erasing memory

Blinking

Paper jam

Blinking

Downloading file

On

Out of ribbon

Blinking

Need to clear print head

Blinking

Ribbon near end

On

Print head open

Blinking

RF communication

Summary of Contents for PRINTRONIX TX210 Series

Page 61: ...56 10 Revise History Date Content Editor...

Page 62: ......