30

6. Troubleshooting

6.1 Common Problems

The following guide lists the most common problems that may be encountered when operating

this bar code printer. If the printer still does not function after all suggested solutions have been

invoked, please contact the Customer Service Department of your purchased reseller or

distributor for assistance.

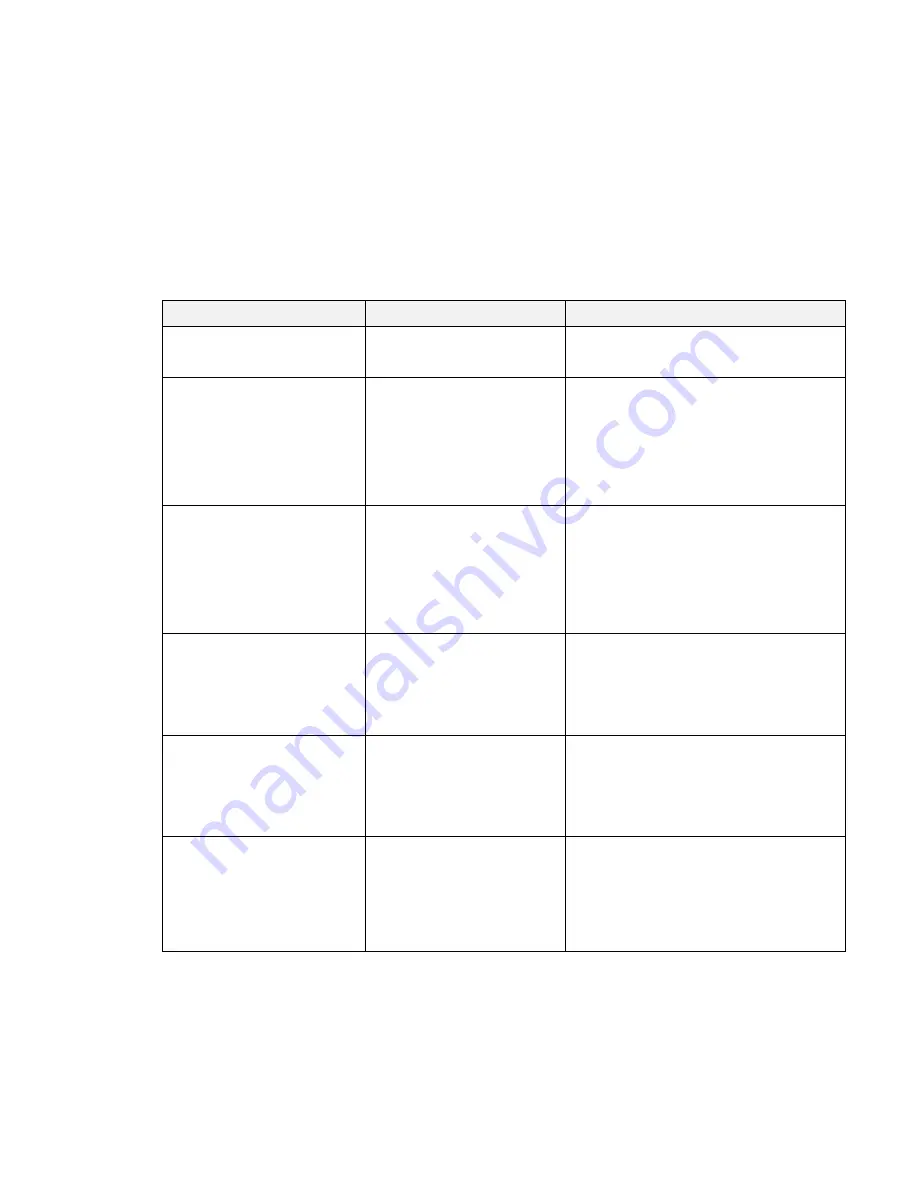

Problem

Possible Cause

Recovery Procedure

Power indicator does not

illuminate

* The power cord is not

properly connected.

* Plug the power cord in printer and outlet.

* Switch the printer on.

- The printer status from

DiagTool shows

“

Head

Open

”.

- The LCD shows

“

Carriage

Open

”.

* The printer carriage is open. * Please close the print carriage.

- The printer status from

DiagTool shows

“

Ribbon End

Err.

” Or “

Ribbon Encoder

Err.

”

- The LCD shows

“

No Ribbon

”.

* Running out of ribbon.

* The ribbon is installed

incorrectly.

* Supply a new ribbon roll.

* Please refer to the steps on section 3.2 to

re-install the ribbon.

- The printer status from

DiagTool shows

“

Out of

Paper

”.

- The LCD shows

“

No Paper

”.

* Running out of label.

* The label is installed

incorrectly.

* Gap/black mark sensor is not

calibrated.

* Supply a new label roll.

* Please refer to the steps on section 3.3 to

reinstall the label roll.

* Calibrate the gap/black mark sensor.

- The printer status from

DiagTool shows

“

Paper Jam

”.

- The LCD shows

“

Paper Jam

”.

* Gap/black mark sensor is not

set properly.

* Make sure label size is set

properly.

* Labels may be stuck inside

the printer mechanism.

* Calibrate the gap/black mark sensor.

* Set label size correctly.

- The LCD shows

“

Take Label

”. * Peel-off function is enabled.

* If the peel-off module is installed, please

remove the label.

* If there is no peel-off module in front of the

printer, please switch off the printer and

install it.

* Check if the connector is plugging

correctly.