TRUE

SPEC SERIES®: STR, STA & STG, ROLL-IN AND ROLL-THROUGH

www

.

truemfg

.

com

11

1

INSTALLATION INSTRUCTIONS

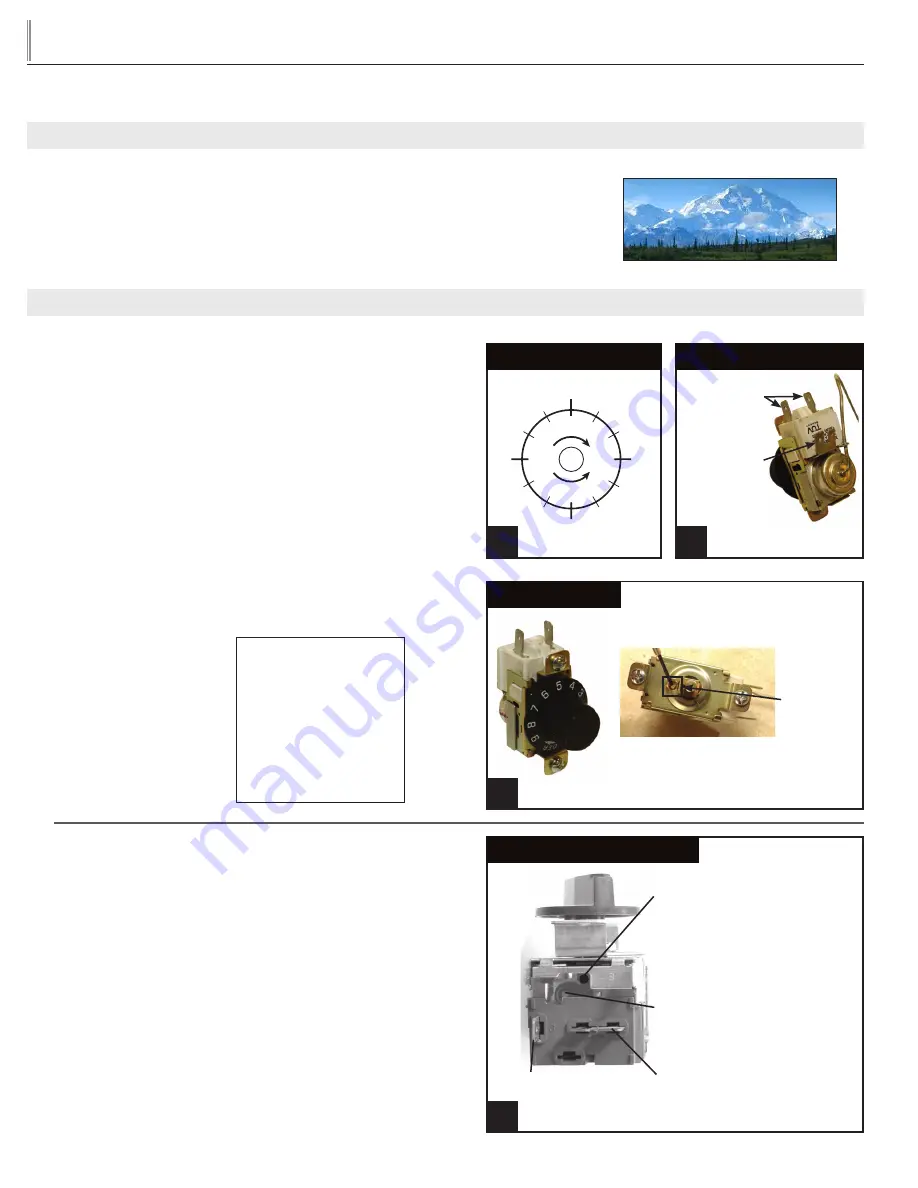

DANFOSS TEMPERATURE CONTROL ADJUSTMENT

FOR HIGH ALTITUDE APPLICATIONS:

REQUIRED TOOLS:

• Allen Wrench (5/64")

• Torx Screw (T-7)

TERMS:

Cut-out

- Temperature sensed by the controller that shuts the

compressor off.

Cut-in

- Temperature sensed by the controller that turns the

compressor on.

WHEN TO MAKE AN ADJUSTMENT TO A MECHANICAL TEMPERATURE CONTROL

OPERATION INSTRUCTIONS:

REQUIRED TOOLS:

• Jewelers Screw Driver (Small Screw Driver)

GE CONTROL INSTRUCTIONS:

The scale to the right may be used as a guide for measuring

degrees of rotation required for altitude correction. See Figure 1.

The arrows indicate direction of screw rotation. Turn calibration

screw clockwise to obtain warmer operating temperatures.

NOTE:

Each 1/4 turn of the calibration screw is equal to

approximately 2 degrees F. Do not make more than 3/4 turn.

After making adjustment, measure temperature during three

cycles before adjusting again.

NOTE:

Only adjust the screw

(small flathead) on the face of

the control (next to the cam).

See Figure 3.

Follow the Altitude Correction

Table to the right.

WA

RMER

C OLDER

60

30

45

40

35

50

55

15

20

25

10

5

We advise to make a mechanical temperature control adjustment only for a high altitude location.

Compressor

Terminals

Ground

Terminal

To adjust the temperature control

take the control knob off to view the

cut-in screw. (See Photo Above)

Front of Temperature Control

Calibration

Screw

1

2

3

Cut-out Adjustment

Screw Allen (5/64" or 2 mm.)

Cut-in Adjustment

Screw Torx (T-7)

Compressor

Connection

ALTITUDE CORRECTION TABLE:

CALIBRATION SCREW ADJUSTS

BOTH CUT-IN AND CUT-OUT

Altitude (Feet)

2000

3000

4000

5000

6000

7000

8000

9000

10,000

Clockwise Turns

7/60

11/60

15/60

19/60

23/60

27/60

30/60

34/60

37/60

Compressor Connection

(double terminal)

HOW TO ADJUST A MECHANICAL TEMPERATURE CONTROL

Altitude Correction

Scale Guide for Measuring

Back of Temperature Control

Bottom of Temperature Control