29

6

» Pneumatic Disc Brake SL7 - SM7

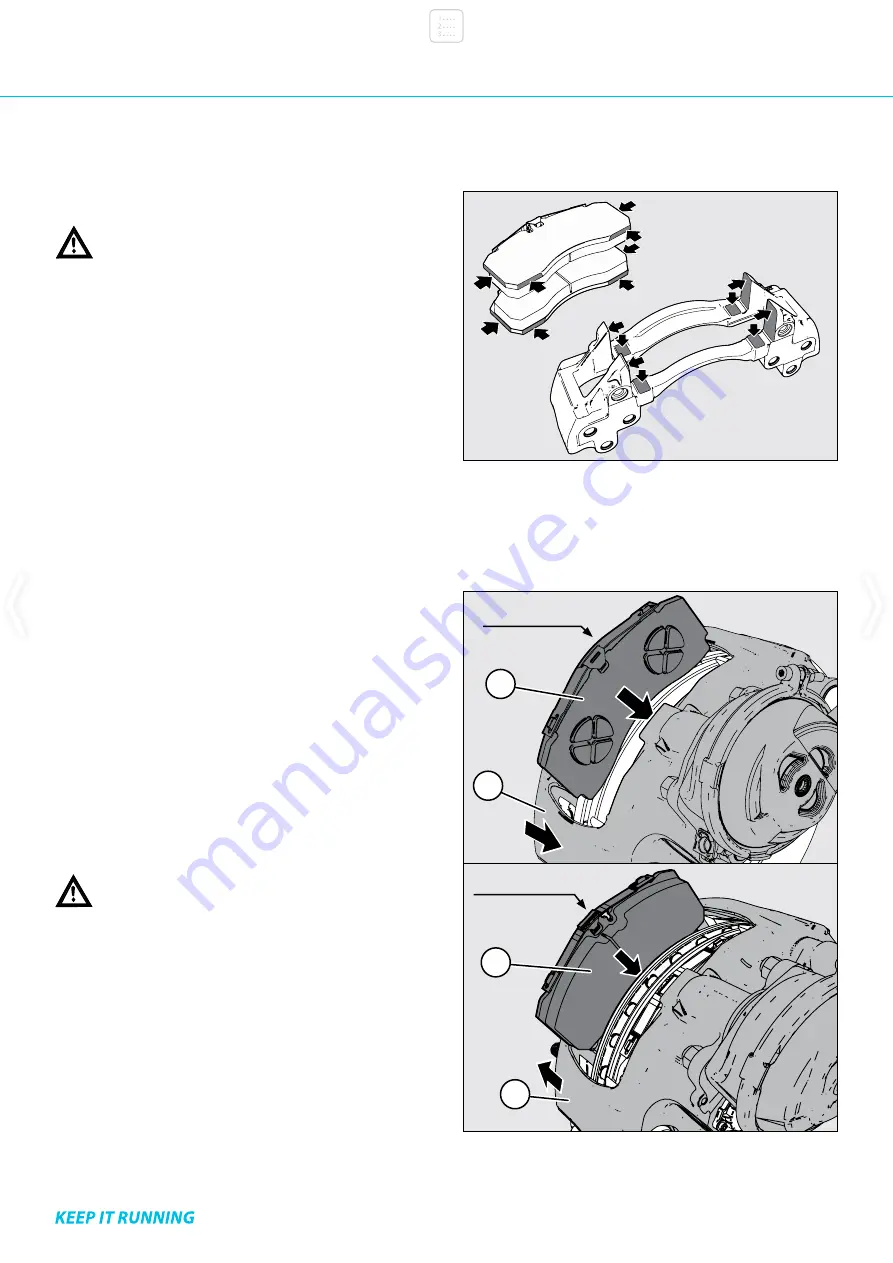

BRAKE PAD REPLACEMENT

6.2.4 - Insert brake pads

6.2 Fitting of Brake Pads

Pads must be changed as an axle set and NOT

individually. Use only pads which are permitted by the

vehicle manufacturer, axle manufacturer and disc brake

manufacturer. Failure to comply with this will invalidate

any Knorr-Bremse warranty.

Inboard brake pad

6.2.2 Check the carrier (2) and rubber seals for damage,

replace if necessary.

Important!

Brake Pad contact surface must be clean, devoid

of moisture and free from any dirt and debris.

6.2.3 Depending on the application, it may be necessary

for the abutments of the carrier and guiding surfaces of the

brake pad to be lightly coated with lubricant (K125122N50)

(see Fig.).

Important!

Do not use copper based lubricant.

Important!

Do not get any lubricant on the pad and/or disc

face or guide sleeve parts.

Refer also to specifications provided by the vehicle, axle and

brake system manufacturer.

Before inserting the brake pads, fully wind back the

tappet and boot assemblies (13) by rotating the shear

adapter (61) in an anti-clockwise direction (see Section

5.2).

6.2.4 Insert brake pads (12) as shown (see fig.).

Note:

With type SL7 and SM7 the inboard brake pad (12

1

) and

outboard brake pad (12

2

) are different, make sure they are

installed in their correct position.

6.2.3 - Areas to apply suitable lubricant

6.2.1 Depending on the intensity of contamination, clean

the brake pad bay area. Use suitable tools (wire brush, caliper

file, blunt scraper).

Important!

Take care not damage the Carrier and/or Rubber

Bush/Guide Sleeve seals.

Outboard brake pad

1

12

2

12

1

1