Installing the plasterboard bulkhead

The DID-E2 active chilled beams must be clad with

a plasterboard bulkhead provided by others after

attachment to the ceiling. When doing so, the fol-

lowing points must be observed:

The plasterboard bulkhead and material are

provided by others.

The plasterboard bulkhead must be self-sup-

porting; the device may not bear any static

loads of the plasterboard bulkhead.

Install the plasterboard bulkhead so that the air

distribution of the device is not affected.

Hygiene VDI6022

If there is a connection between the secondary

air and the plasterboard bulkhead (e.g.

Ä

the VDI6022 must be observed, e.g. provide a

cleaning option for the plasterboard bulkhead and

for the heat exchanger of the ventilation device.

We therefore recommend direct secondary air

intake through the grille into the ventilation device

Ä

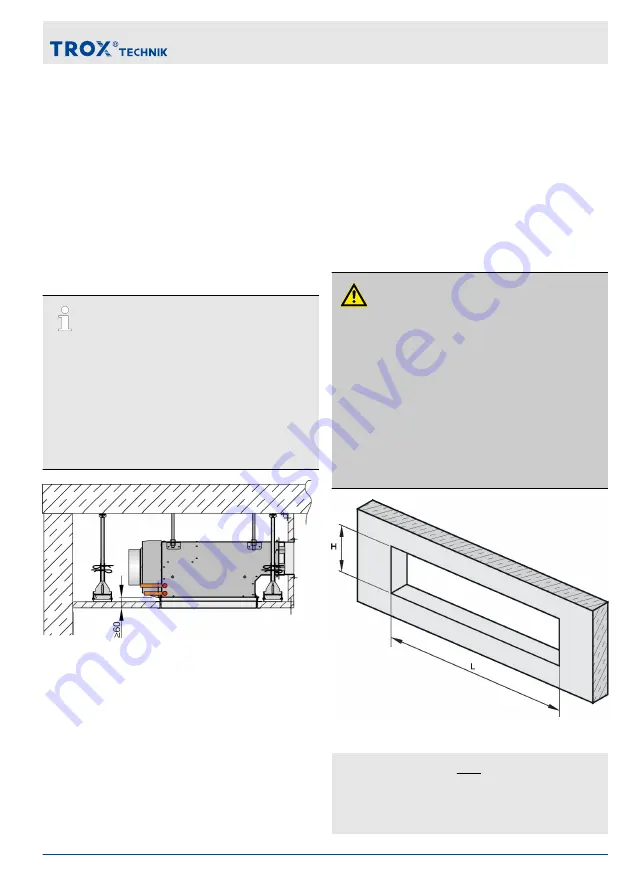

Fig. 6: DID-E2 installation example without grille

1

Extension spigot for supply air (optional)

2

Plasterboard bulkhead (provided by others)

3

Suspension (provided by others)

4

Installation subframe for secondary air grille

(optional)

Assembly of the installation subframe (optional)

Create an assembly opening in accordance

with nominal size of the secondary air grille.

Fasten by clamping to the plasterboard bulk-

head (clamping range 9-30 mm)

The installation subframe can be assembled

directly under the device (direct connection to

the device) or at a distance from the device.

The VDI 6022 must be observed here, e.g.

provide cleaning option for plasterboard bulk-

head.

CAUTION!

Risk of injury from a falling secondary air

grille!

If the secondary air grille is not secured, there is

a risk of injury from the grille falling.

Safety cables are provided on the optional instal-

lation subframe for securing the grille. When

adjusting the grille, attach the safety cables to the

grille.

If an installation subframe is not being used, the

grille must be secured on site against falling.

Fig. 7: Installation opening for a ventilation grille

Installation opening with installation subframe

L = Grille length to be ordered

H = Grille height to be ordered

Fasten the device

Active chilled beams Type DID-E2

9