Installation Instructions

P & Q 600 SERIES DUAL COIL

“3 WIRE” DC SOLENOIDS

MOUNTING SOLENOID AND ELECTRICAL CONNECTIONS

1. Securely bolt the solenoid in its mounting position, making sure to align the plunger as straight as possible

to the connecting linkage.

Do Not Connect the linkage to the lever at this time.

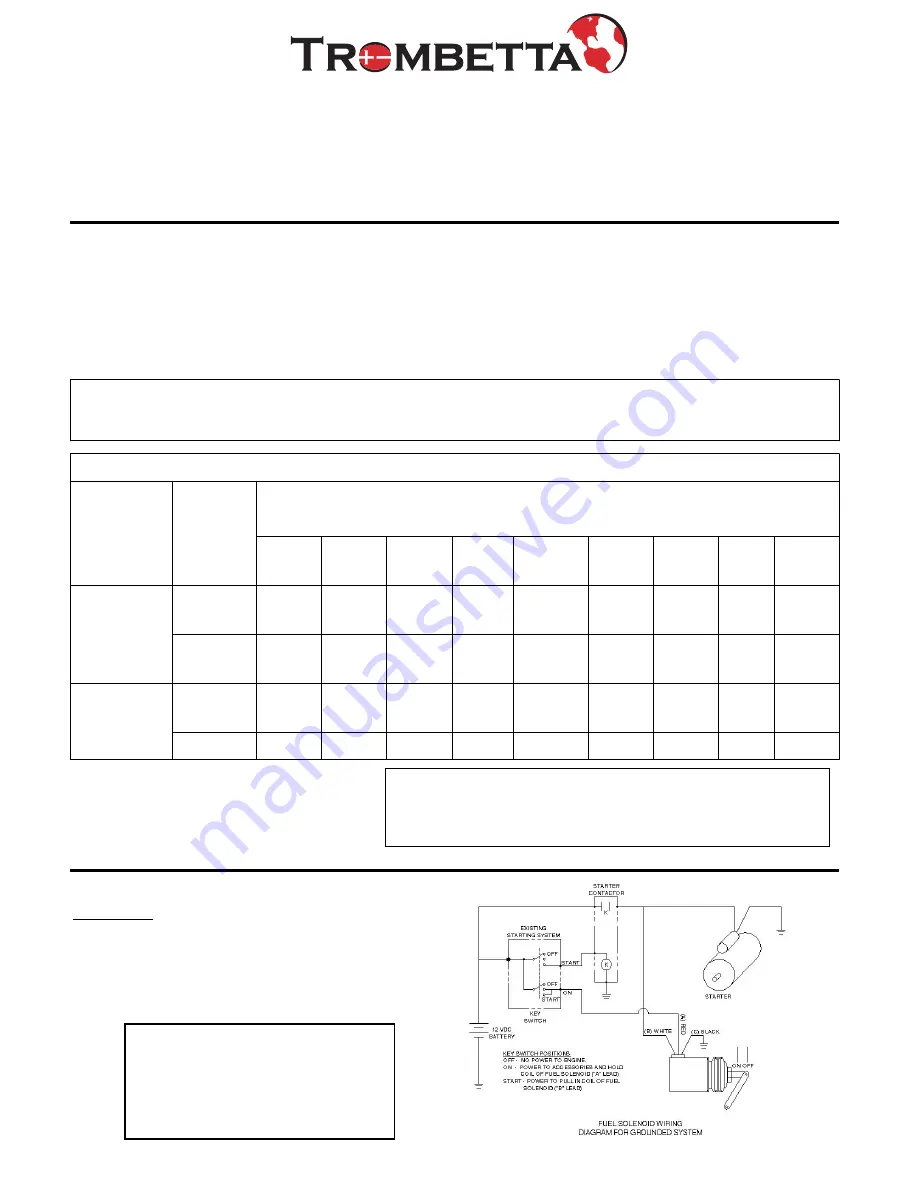

2. Using the “Wire Gage Recommendation Table” below, select the proper wire size for your installation.

Wire the solenoid for your installation as shown on page 2 of these instructions.

IMPORTANT

To insure proper solenoid operation, the total connecting wire length for both leads combined, must not exceed the

recommended maximum lengths indicated in the Wire Size Recommendation Table below:

Solenoid Lead Identification:

WHITE

PULL COIL / HIGH CURRENT

RED

HOLD COIL / LOW CURRENT

BLACK

GROUND

CAUTION!

Coils that burn out due to improper electrical connections are not

covered by factory warranty. If you have any questions concerning

proper installation, contact the factory before proceeding.

1

160

100

64

40

25

16

10

----

----

24 VDC

40

25

16

10

6

4

2.5

----

----

12 VDC

P & Q

612 613

240

150

96

60

38

24

15

----

----

24 VDC

60

38

24

15

9.5

6

4

-----

-----

12 VDC

P & Q 610

6GA

8GA

10GA

12GA

14GA

16GA

18GA

20GA

22GA

Maximum lead length or all leads (in feet)

Wire Gage/Size

Rated

Voltage

Solenoid

WIRE SIZE RECOMMENDATION TABLE

SYSTEM # 1 - “ON-TO-RUN”, FUEL SHUTDOWN

APPLICATIONS

Solenoid is wired into existing starting system of the engine.

No added “high current” relays are required since the solenoid

“pull coil” (high current) power comes directly from the engine

starter. Wire the solenoid as shown in the schematic below:

Note

: If wired as shown to the right, and

solenoid is improperly adjusted, solenoid

plunger will release when operation is

shifted to the “holding mode” after the

engine starts. If the plunger releases, no

damage will occur to the solenoid. Only

readjustment of the linkage is required.