Appropriate

fitting

Water pipe

Fig.12

Dual control thermostatic mixer

10

FITTING THE FIXED HEAD

PIPEWORK

Complete the outlet pipework, ending in a

½” BSP x 15mm female thread elbow

(fig.10)

.

Finish the wall so that it is flush with the fitting

(fig.11)

.

Note:

This fitting is not supplied as variations

in installations require the selection of the most

suitable fitting.

MAKING GOOD

Fit the tiling shroud over the mixer body and

make good the wall, tiling etc. and around the

fixed head outlet.

Note that if the tiles are accurately cut to match

the profile of the shroud, then the faceplate will

seal around the hole in the tiles, and the valve

unit can be serviced without the need to break

any tiles.

Make sure the grout lines are flush with the tiles

in order to provide a smooth sealing surface for

the face plate.

FITTING THE FACEPLATE AND

CONTROLS

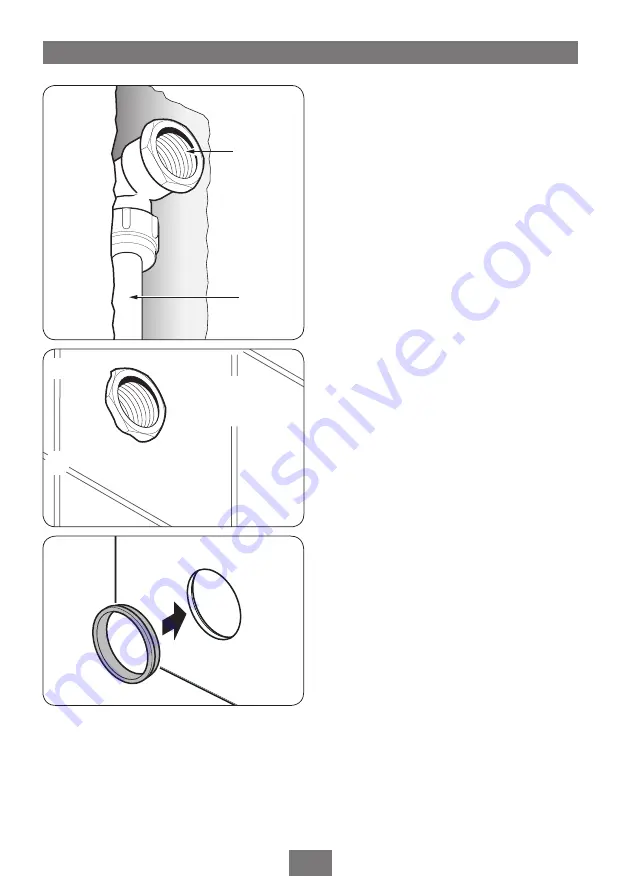

Insert the rubber trim seal into the temperature

opening of the face plate

(fig.12)

.

Fit the face plate over the valve controls and

slide tight up to the wall. Make sure the rubber

seal stays in place as it slides over the trim. A

smear of liquid soap on the seal will ease this

procedure.

The face plate incorporates a silicon sponge

backing that seals against a smooth wall.

Fitting the temperature control

Temporarily fit the temperature control knob

onto the splined adaptor

(fig.13)

.

DO NOT secure with the grub screw until

the commissioning procedure is complete.

Fitting the On/Off flow control

Insert the ‘O’ ring seal into the recess in the

back of the threaded trim ring

(fig.14)

. Screw

the threaded trim ring onto the On/Off spindle

until it engages into the face plate opening.

Fig.10

Fitting should

be flush with

the finished wall

Fig.11