23.

If connecting rod is not in the down position plug unit in and cycle unit to get connecting rod into down

position.

24.

With piston slots aligned slide pump/filter manifold onto connecting rod #56 Diagram “B”. Push

pump/filter manifold towards crank housing # 53 to line up dowel pins then thread mounting bolts #25

through pump filter manifold and thread into crank housing #53. Tighten firmly with5/16” Hex wrench.

25.

Reattach transducer #30 to the back of pump/filer manifold.

26.

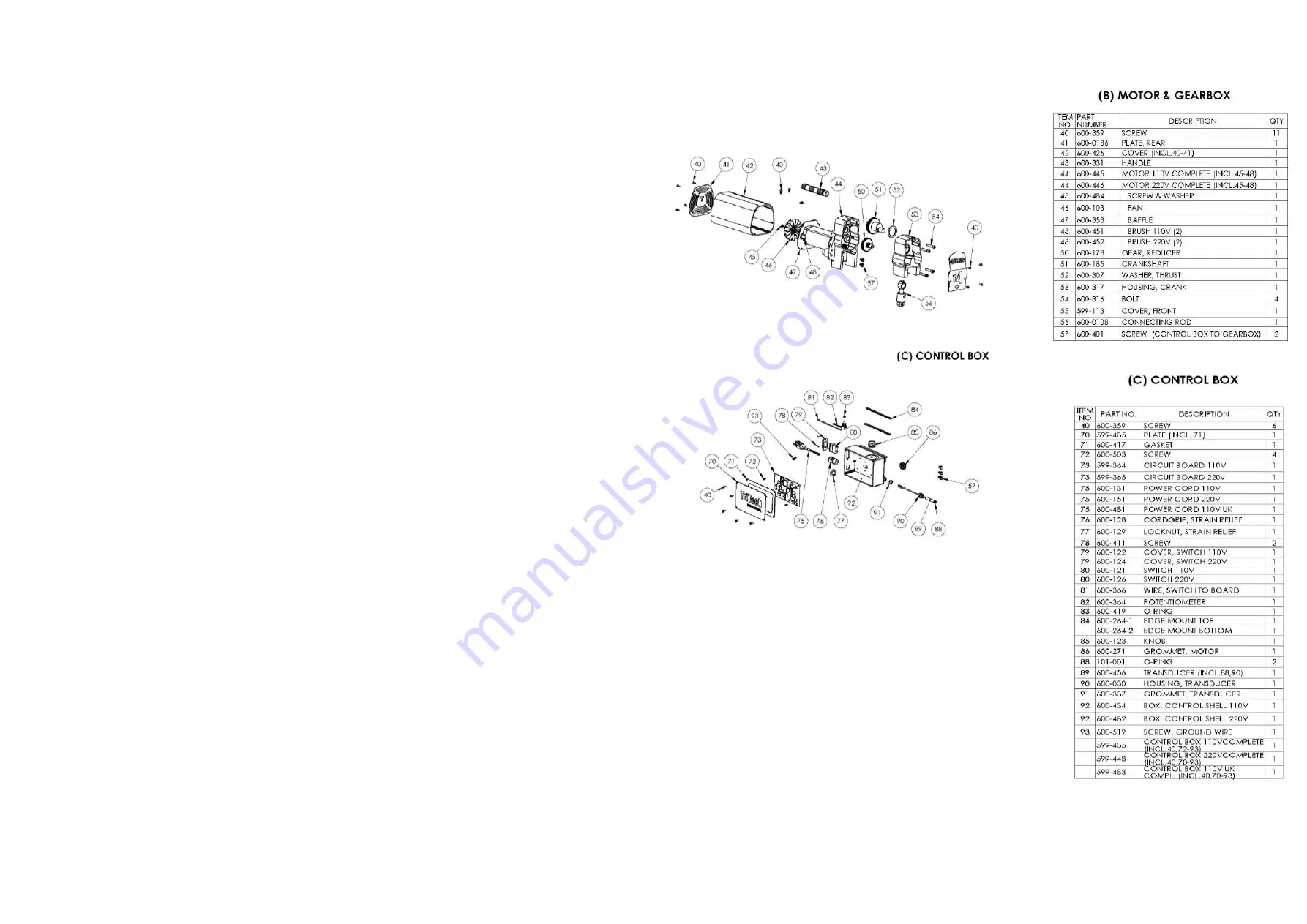

Reinstall crankshaft cover plate #55 with 4 screws #40. See diagram “B”.

27.

Reattach suction set.

28.

Pour Trilube through slot in cover plate #55, diagram “B”.

REPLACE BY-PASS VALVE

1.

To replace the pressure relief valve #27 knock pin #29 through black handle #28.

2.

Remove black plastic handle and cap with indexing pin which exposes pressure relief valve.

3.

Using a 3/4” open end unthread by pressure relief valve. Inspect. Replace if worn.

REPLACE FILTER

1.

To replace the paint filter remove filter bowl #1 from fluid manifold by unthreading counter

clockwise.

2.

Remove filter #3 and spring support #4. Most times filter can just be cleaned but if damaged replace.

REPLACE TRANSDUCER

1.

To replace transducer hold wire tube of #31 with plyers, unthread transducer housing #30 from

pump/filter manifold.

2.

Remove mounting screws # 25.

3.

Remove 4 screws for crank housing cover plate # 55.

4.

With a flat blade screwdriver pry pump/filter manifold downward till it clears locating pins and slide

forward but do not remove.

5.

Remove 4 screws #40 and Control box cover plate #70.

6.

Unplug transducer from circuit board. See diagram “B”.

7.

Guide transducer wire out of control box.

8.

To replace guide replacement transducer through grommet #91 and reconnect to circuit board.

9.

Thread transducer into pump/filter housing.

10.

Replacement of transducer requires no calibration of pressure control. To ensure new transducer

functions properly follow Start up procedure.

Summary of Contents for 200-517

Page 6: ......