QSH4218 Manual (V1.03 /13-November-2007)

9

Copyright © 2007, TRINAMIC Motion Control GmbH & Co. KG

5.2 Motor

Current

Setting

Basically, the motor torque is proportional to the motor current, as long as the current stays at a

reasonable level. At the same time, the power consumption of the motor (and driver) is proportional

to the square of the motor current. Optimally, the motor should be chosen to bring the required

performance at the rated motor current. For a short time, the motor current may be raised above this

level in order to get increased torque, but care has to be taken in order not to exceed the maximum

coil temperature of 130°C respectively a continuous motor operation temperature of 90°C.

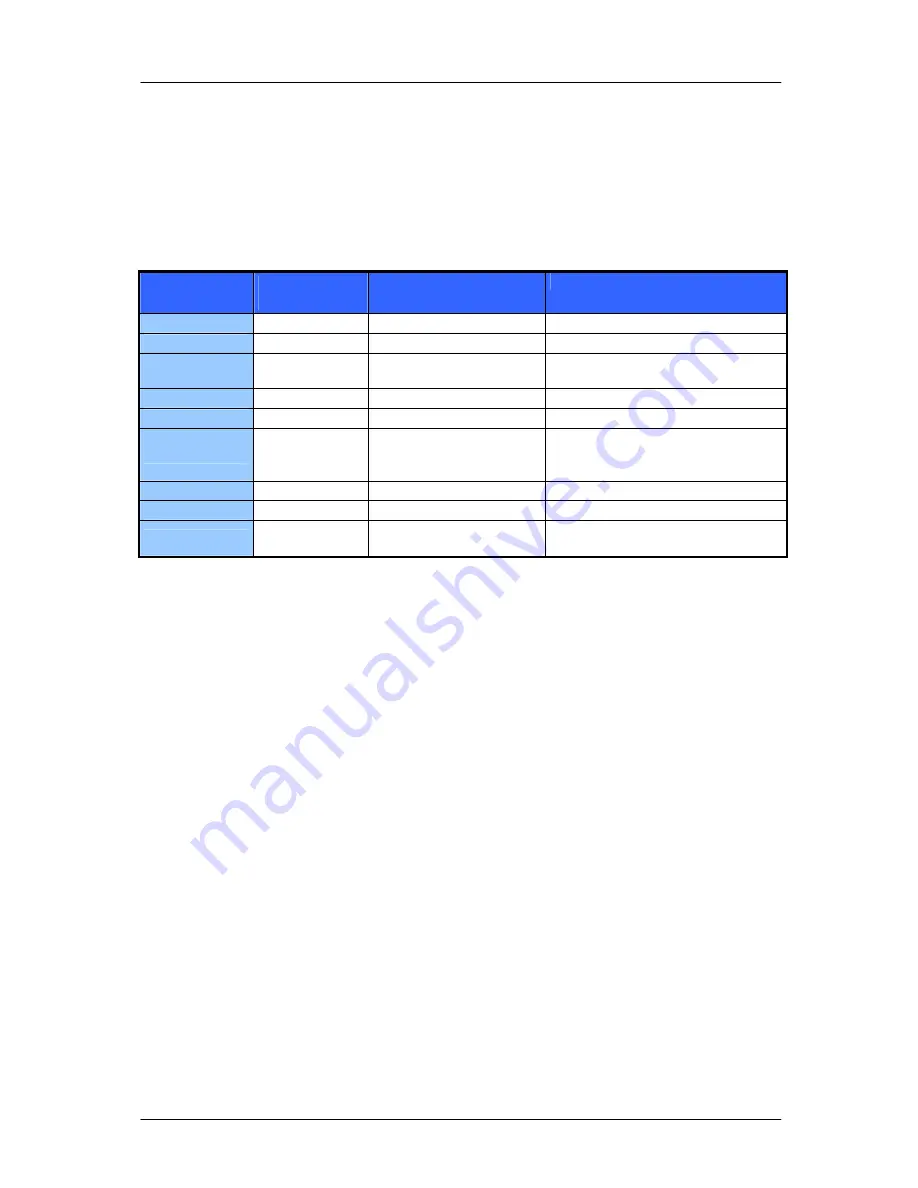

Percentage of

rated current

Percentage of

motor torque

Percentage of static

motor power dissipation

Comment

150%

≤

150%

225%

Limit operation to a few seconds

125%

125%

156%

Operation possible for a limited time

100%

100%

100%

= 2 * I

RMS_RATED

* R

COIL

Normal operation

85%

85% 72%

Normal operation

75%

75% 56%

Normal operation

50%

50% 25%

Reduced microstep exactness due to

torque reducing in the magnitude of

detent torque

38%

38% 14%

-“-

25%

25% 6%

-“-

0%

see detent

torque

0%

Motor might loose position if the

application’s friction is too low

Table 5.1: Motor current settings

Hints:

Q: How to choose the optimum current setting?

A1:

Generally, you choose the motor in order to give the desired performance at nominal current.

For short time operation, you might want to increase the motor current to get a higher torque than

specified for the motor. In a hot environment, you might want to work with a reduced motor

current in order to reduce motor self heating.

The Trinamic drivers allow setting the motor current for up to three conditions:

-

Stand still (choose a low current)

-

Nominal operation (nominal current)

-

High acceleration (if increased torque is required: You may choose a current above the nominal

setting, but be aware, that the mean power dissipation shall not exceed the motors nominal

rating)

A2:

If you reach the velocity limit, it might be a good idea to reduce the motor current, in order to

avoid resonances occurring. Please see the hints on choosing the driver voltage.

Q: What about energy saving – how to choose standby current?

A1:

Most applications do not need much torque during motor stand-still. You should always reduce

motor current during stand still. This reduces power dissipation and heat generation. Depending on

your application, you typically at least can half power dissipation. There are several aspects why

this is possible: In stand still, motor torque is higher than at any other velocity. Thus, you do not

need the full current even with a static load! Your application might need no torque at all, but you

might need to keep the exact microstep position: Try how low you can go in your application. If

the microstep position exactness does not matter for the time of stand still, you might even reduce

the motor current to zero, provided that there is no static load on the motor and enough friction in

order to avoid complete position loss.