BB-100 Manual (v 1.00 / April 5th, 2006)

8

Copyright © 2006, TRINAMIC Motion Control GmbH & Co. KG

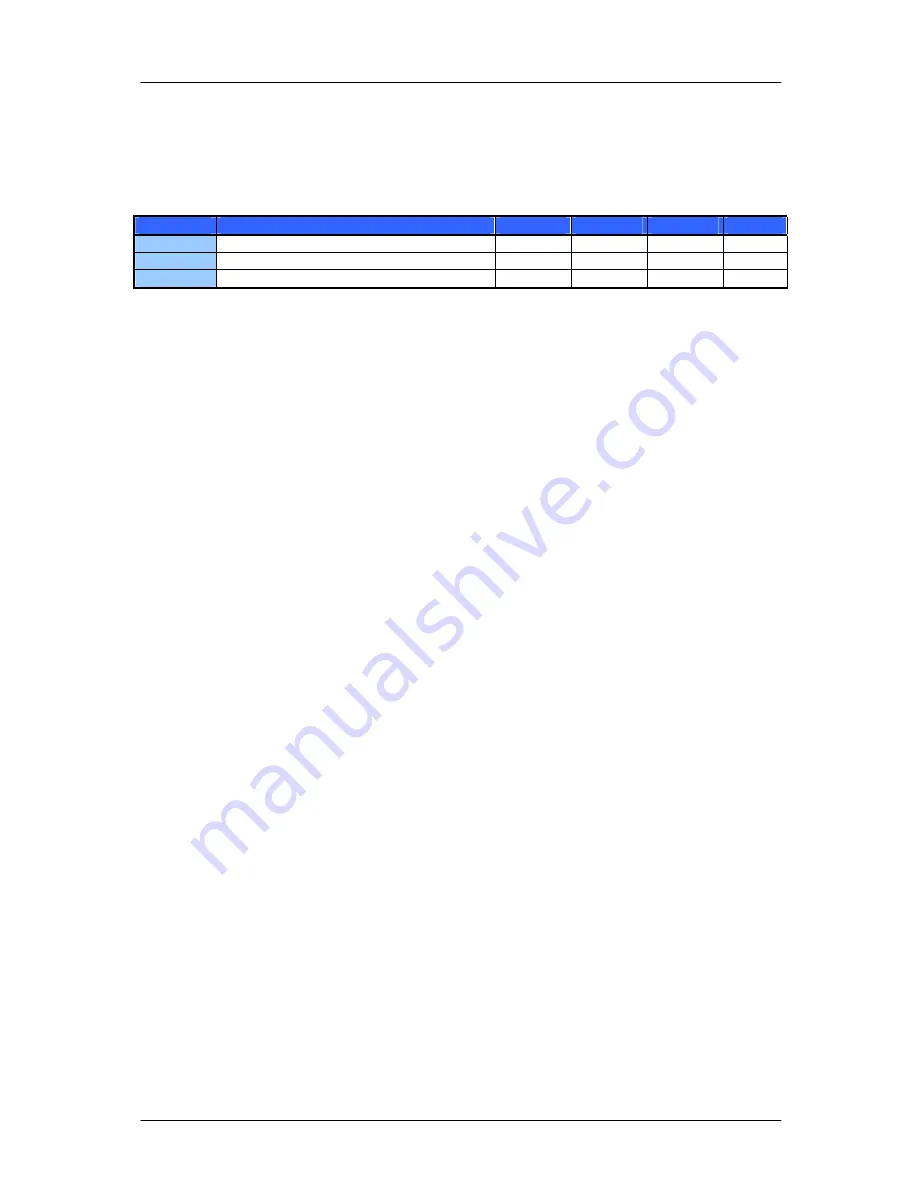

4 Operational Ratings

The operational ratings show the intended / the characteristic range for the values and should be used

as design values. In no case shall the maximum values be exceeded.

Symbol

Parameter

Min

Typ

Max

Unit

VS

Power supply voltage for operation

15

50

V

T

ENV2A5

Environment temperature at 2.5A RMS

-25

60

°C

T

ENV3A5

Environment temperature at 3.5A RMS

-25

40

°C

Table 4.1: Operational Ratings (pls. refer [TMCM-035] and [TMCM-100]

4.1 Motors

The TMCM-035 onboard the BB-100 operates a wide range of bipolar 2-phase stepper motors. Motors

with nominal currents above 5 amperes (peak) can be used, too. Please refer [TMCM-035] for details.

Low supply voltage limits can be disregarded because the drivers operate in current regulating mode.

The minimum coil resistance is not limited, even a short circuit does not lead to damage. High coil

resistance (e.g. above 10 ohms) might cause limited dynamical performance and/or reduced

maximum motor speed. A coil inductance in the range of 1 mH results in good current regulation with

low current ripple. Even inductance lower than 1 mH is allowed but the inductance of typical stepper

motors is above 1 mH.

5 Getting Started

The power supply has to be disconnected when plugging in a TMCM-035 or TMCM-100 module

into the BB-100. Do not connect or disconnect the motor while the unit is powered. Connecting

or disconnecting the motor while the unit is powered might damage it.

5.1 Power Supply and Motor Connection

The stepper motor must not connected or disconnected when it is powered, because this can

destroy the power stage of the TMCM-035 module due to high voltage generated by the

inductance of the coils of the stepper motor.

An unregulated supply voltage (V+) is sufficient for the BB-100, but it must not exceed the range from

15 to 50 Volts. Generally, high supply voltage (e.g. 24V, 40V) that is compatible with the stepper motor

should be preferred. A higher supply voltage results in a better dynamic behavior of a stepper motor.

The alternative supply voltage input marked with the diode symbol features a reverse current

protection for the power supply. Reverse currents might occur during fast deceleration at high

currents. A low end power supply might be damaged by reverse currents. This diode also features a

reverse polarity protection for the BB-100 with the TMCM-035 and TMCM-100. The integrated switch-

mode regulator provides the required 5V supply voltage for the modules