2

Table of contents

1.Health and safety precautions:

3

1.1 General:

3

1.2 Electrical/maintenance

3

1.3Installation:

3

2. Transporting, unloading and storage of tanks:

4

3. Introduction:

6

4. The wastewater purification process:

7

4.1 Stage 1: Existing primary settlement chamber:

7

4.2 Stage 2:Aeration (treatment) chamber:

7

4.3 Stage 3:Final settlement chamber:

7

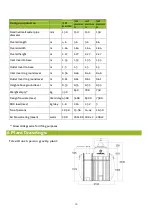

5. Plant dimensions:

8

6. Plant drawings:

10

7.Technical drawings of Tricel pumped plant:

14

8.Lid locking points:

14

9.Manhole risers (deep inverts):

15

10. Installation:

16

10.1 Pre-installation tank inspection:

16

10.2 Quick installation guidelines:

17

10.3 Detailed installation information:

18

10.3.1 Excavation size:

19

10.3.2 Eexcavation dept:

20

10.3.3 Loadings:

21

10.3.4 Control of groundwater

21

10.4 Gravel installation:

21

10.4.1 Tank base/plinth:

22

10.4.2 Installing onto the base/plinth:

22

10.4.3 Backfilling dry site

22

10.5 Concrete installations:

23

10.5.1 Tank base/plinth:

23

10.5.2 Installing onto the base/plinth:

23

10.5.3 Backfilling a wet site:

24

10.6 Plinth and backfill specifications:

25

10.6.1 Gravel backfill specifications

25

10.6.2 Concrete backfill specifications:

26

10.6.3 Top soil

26

11. Electrical installation:

27

12. Plumbing the system:

27

13. Ancillary installation notes:

28

13.1 Ventilation:

28

13.2 Control housings:

28

13.3 Access:

28

14. Plant operation:

29

15. Disposal of treated water:

29

16. Maintenance:

30

16.1 Regular maintenance:

30

16.2

16.2.1 Yearly service (available from your supplier):

30

16.3 Production of sludge:

31

17. Operation conditions:

32

18. Troubleshooting:

33

19. Certification:

37

TTM T103 Rev04 – 08 April 2014