Tightening your compression:

If your bars start to shake or move side to side, this means your compression needs to be tightened. Do so by

removing your handle bars and using a allen key to tighten the compression ring. Turning it in a clock- wise

direction, tighten until some pressure is felt in the allen key. You want to be able to still spin your forks freely,

however if over tightened, you can restrict the movement and damage your compression or headset. This

should be done by an adult or a professional mechanic.

Lubricating your bearings:

You will need to take off your wheels to lubricate your wheel bearings. Insert the 6mm allen keys, in each axle

head and turn them anti clock- wise (1x6mm for rear axle). The wheels may need some encouragement to slide

out. Using a damp cloth wipe off any dirt or grime on your wheels and bearings. Using bicycle bearing oil,

place 3 to 4 drops directly on the bearing covers and allow the oil to sink in. If the wheels do not spin freely

after this you may need to replace the bearings.

Cleaning your scooter:

Never use alcohol or any strong cleaning agents to clean your scooter. Doing so may damage paint or fragile

materials. Warm water and a damp cloth should be enough. Avoid putting water directly on the grip tape and

never submerge your scooter in water.

SAFETY REMINDERS –

When using this scooter for the first time, check that all the bolts are tightened. Inspect all moving parts,

including wheels and headset and ensure they are operating smoothly. -Check and secure all bolts before

every ride. Loose parts may damage your scooter or increase the risk of a fall. - Replace worn or broken parts

immediately. - Ensure you are wearing all required safety equipment before operating this scooter.

MAINTENANCE

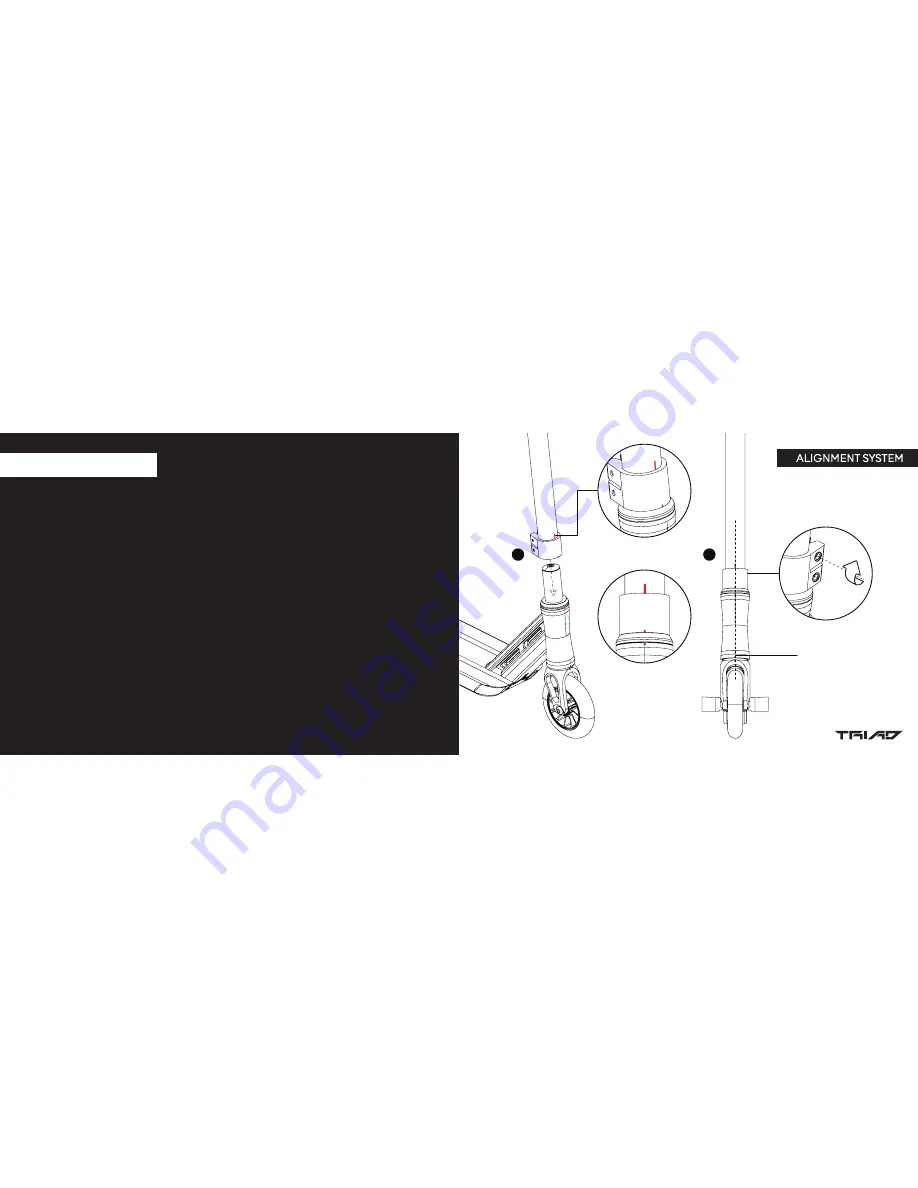

Once the clamp is firlmy in position

tighten bolts to 8Nm with 6mm hex key

Insert handlebar & clamp

to the fork using the indicators

for precision alignment

Laser etched

center alignment

indicators

2

1

Instructional diagram for Infraction

Tightening order - 1,2 with quarter turns,

repeat this process to ensure both bolts are

tightened equally

Once the clamp is firmly in position

tighten bolts with a 6mm hex key