Using a 8mm punch align the hole in

the throttle lever (5) with the holes in

the handle (4). Using a small hammer

fit the throttle lever pin (7).

Tube to Handle Assembly.

Hold

handle tube (11) in vice, about six

inches (150mm) away from the valve

assembly.

Ensure that the threads of the Handle

and Tube are of Loctite 243 or a

similar product and free of oil; apply a

bead to the first few threads of the

Handle and screw in the handle (4)

until hand tight.

Looking from the top of the handle,

using a soft-faced hammer, strike the

air inlet boss downward in a clockwise

direction until tight.

Body to Handle Tube Assembly

Ensure that the thread of the lock nut

(16) is clean and free of oil; apply a

bead of Loctite 243 or a similar

product to the first few threads of the

lock nut (16).

Hold the handle tube (11) firmly in a

vice, take extra care while inserting

the spring (15) into the tube not to

contaminate the tube threads with

grease, otherwise the thread lock

adhesive will not cure, screw in the

locknut (16) until hand tight.

Using a suitable wrench, tighten the

locknut to a torque of 100lbs/ft

(135.5Nm).

Knock over the tab washer onto

one of the locknut flats.

Lubricate the mating faces of the

cowl and body with a general

purpose bearing grease.

Slide cowl (8) and spring (12)

down onto body assembly and

align the dimple on the body with

the dimple on the cowl, align the

holes using a 9mm bar.

Drive one of the spiral securing

pins (9) through the free hole.

Remove 9mm bar and fit the

second spiral pin (9).

It is important that the pins are

fitted centrally in the cowl.

Remove tool from vice and re-

position side handle (10) and

tighten the M8 caphead screw.

Machine Storage

Storage: over 3 months.

Clean the outside of the machine

and inspect the piston and

cutterhead for wear, replace any

worn parts as required.

Put a liberal amount of lubricant

into the air inlet of the tool and run

the tool for a few seconds to

disperse the oil around the tools

internal components.

Lubricate the exposed part of the

piston and cylinder.

(See recommended lubricants)

Cover the machine to protect it:

Store the machine in a dry place.

When next used, continue as per

“Starting work section”.

Disposal

When the tool and its accessories

are taken out of service for disposal,

it is recommended that: -

Dismantle into component form,

segregated according to material

composition and disposed of using

waste recycling processes specified

by local regulations.

Machinery Directive

Information

This tool has been designed and

produced in accordance with the

following directive:

2006/42/EC Machinery Directive

and applicable harmonised standard:

EN ISO 1 1148-4:2010

If your company has any problem

with our products or would like to

discuss

the

possibility

of

an

improvement being made to them,

then please do not hesitate to contact

us. Your comments are both

important and appreciated.

OPERATION / MAINTENANCE

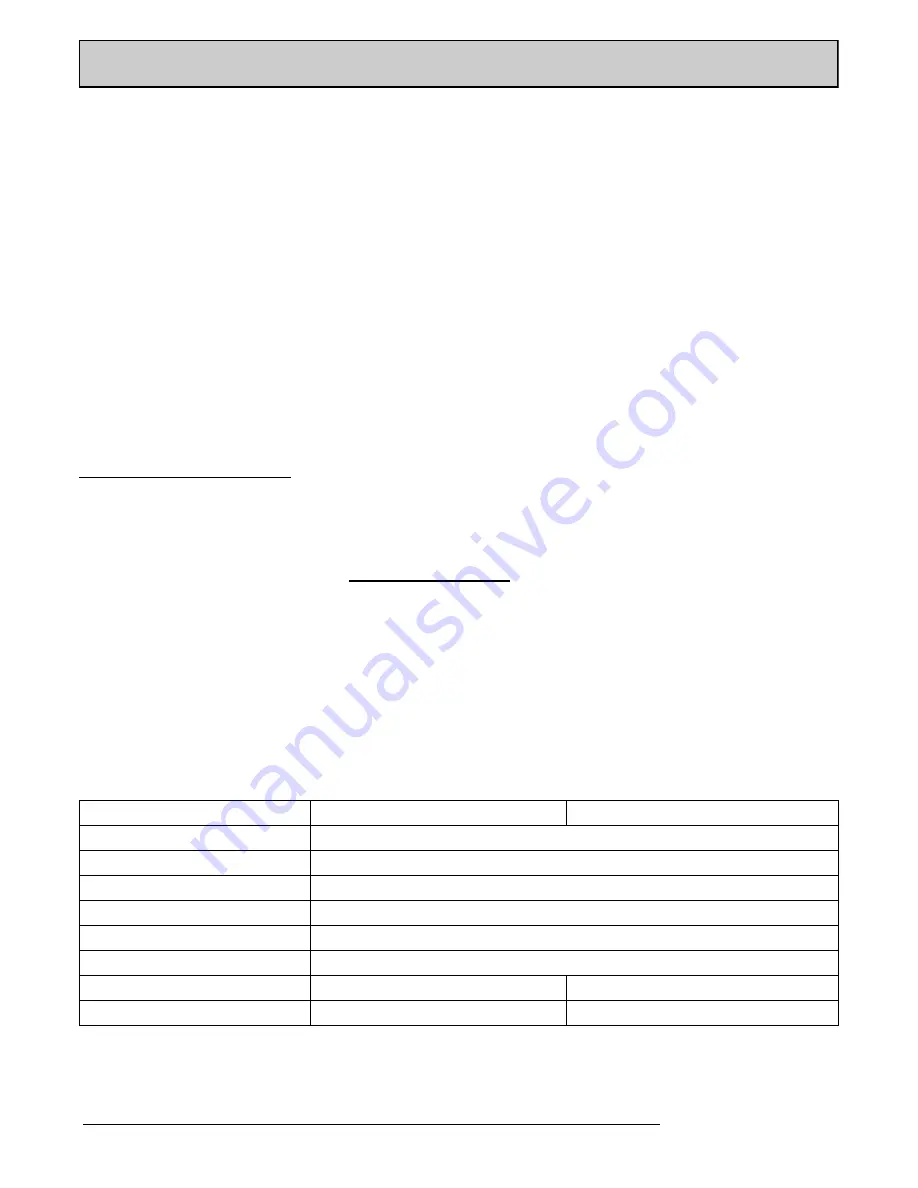

TECHNICAL SPECIFICATIONS

COMPACTOR

SCABBLER

Length

1270mm (50)”

Weight

21.5kg (47.3lbs)

Blows per minute

1300

Air Pressure

6.2 bar (90psi)

Air Consumption

11.61 lps (25cfm)

Sound pressure level

98.0db(A)

Vibration Level (H1)*

3.5m/s

2

(K= -0% +40%)

4.2m/s

2

(K= -0% +40%)

Vibration Level (H2)*

2.9m/s

2

(K= -0% +40%)

3.9m/s

2

(K= -0% +40%)

*H1, Indicates test taken from the primary handgrip location at the trigger.

*H2, Indicates test taken from the secondary handgrip location.

Users should be aware that for other applications, the vibration readings may be higher than specified.

The 4.2 m/s² value is only applicable to compaction of MOT (DOT) type 1. sub-base material