Instruction manual OPTIMAL VP150-VP320 (0911)

trejonindustries.se

7

CAUTION! WARNING! CRUSH HAZARD!

Avoid getting caught between

the central piece and the plough wings

3 Technical

description

The wings of the V-plough can be individually adjusted to pivot forwards and backwards: 30° with

model 150, 40° with models 210 and 240, and 35° with models 280 and 320, and see figure 1.

Thanks to this, the plough can be used in a pointed, diagonal, or Y position:

3.1 Attachment

The attachment is articulated for a horizontal tilt of up to 8°.

With normal driving the tilt should be 8°, see fig. 2, pos. A. Always supply details of the type of

mounting system or the suspension of the vehicle onto which the plough is to be installed when

ordering a V-plough.

3.2 Skid

shoes

The V-plough is equipped with two skid shoes which can be set to different heights, see figure 2,

pos. B. During the season’s first ploughing, it is most suitable to set the skid shoes to a lower

position in order to avoid unnecessary wear on the scraper steels. After that the skid shoes should

be set to the same height as the scraper steels.

3.3 Scraper

steels

The scraper steels are reversible. Each mouldboard is spring-loaded thus reducing the risk of

damage when an obstacle is hit.

The plough is delivered with scraper steels with bent-over edges (plough blades for pavements)

that reduce the risk of damage if a kerb is hit. These scraper steels can be reversed by shifting the

left or right mouldboard.

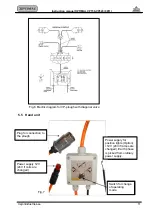

3.4 Hydraulics

The V-plough is powered by a double-acting hydraulic outlet connected to the tractor’s hydraulic

unit or the third or fourth hydraulic function of the loader. The plough is equipped with an

electric/hydraulic diagonal valve which make it possible to operate the wings individual or both

together parallel (in diagonal mode). The electric/hydraulic diagonal valve is operated by a hand

unit in tractor’s cabin.