TRX-4 • 25

ADJUSTING YOUR MODEL

Important:

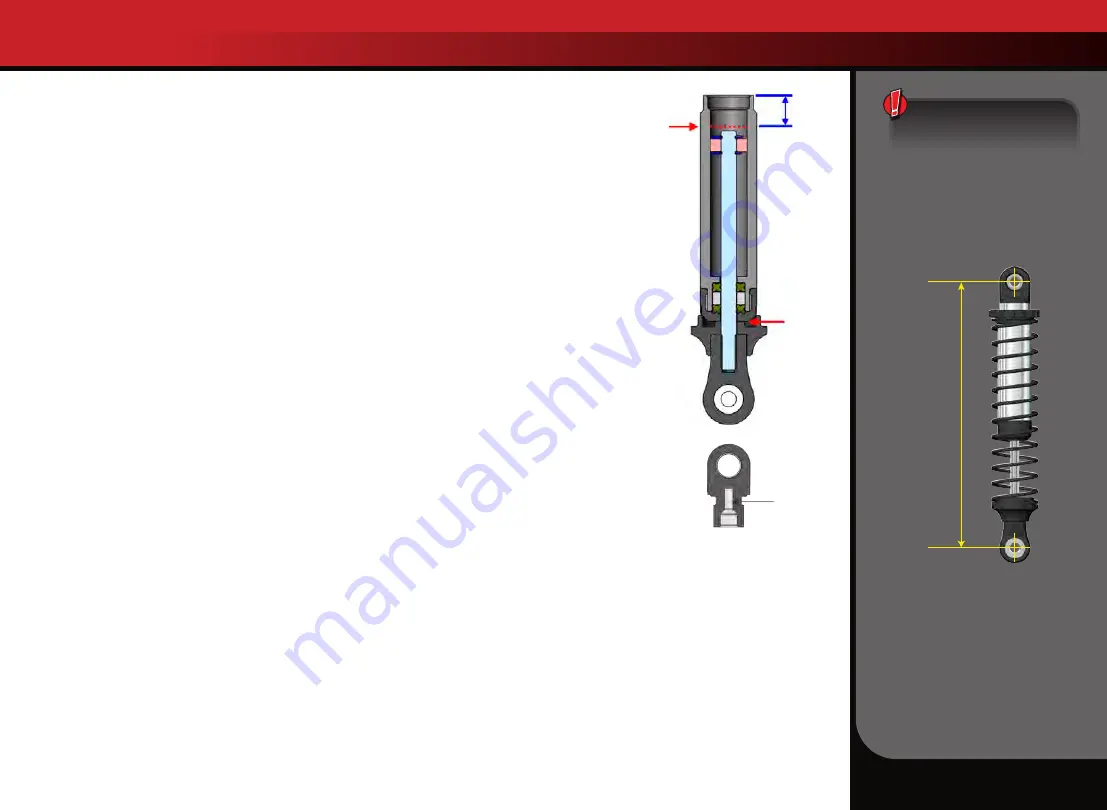

The shocks are

assembled at the factory

with a center-to-center

distance (between the rod

end balls) of 90mm. Any time

the shocks are removed and

disassembled, this distance

should be checked to ensure

proper operation of the

suspension.

90mm

Adjustment procedures for alignment, spring rate, damping, steering,

and ride height are covered here.

SUSPENSION TUNING

Springs

TRX-4’s front springs (0.30 rate, white stripe) and rear springs (0.54 rate,

green stripe) have been carefully selected to provide full suspension

articulation and support for the weight of the vehicle body.

Using different bodies with lighter weight will allow you to use lower

rate springs to increase traction and suspension articulation when

traversing difficult terrain. Lighter springs can be used since the portal

axles use gear reduction to reduce undesirable torque twist.

Ride Height Adjustment

TRX-4’s ride height can be finely tuned by adjusting suspension sag

via the preload adjusters on the shock bodies. Thread the preload

adjuster down the shock body to raise TRX-4’s ride height, or thread

the adjuster up the shock body to lower ride height. The front left

preload adjuster will require more threading to compensate for

the weight of the motor. If threading the preload adjusters to the

maximum ride height position still allows more suspension sag than

you prefer, stiffer springs should be installed.

SHOCK TUNING

Shock Oil

The 4 oil-filled aluminum shocks (dampers) effectively control the

suspension movement. Changing the oil in the shocks can vary the

suspension damping effect. Changing the oil to a higher viscosity oil

will increase damping. Lowering the viscosity of the oil will cause the

suspension damping to be reduced.

Damping should be increased (with higher viscosity oil) if the model is

bottoming easily over jumps or when stiffer springs are installed. Damping

should be decreased (with thinner viscosity oil) if the model is hopping

over small bumps and feels unstable or when softer springs are installed.

The viscosity of shock oil is affected by extremes in operating temperature;

an oil of certain viscosity will become less viscous at higher temperatures

and more viscous at lower temperatures. Operating in regions with cold

temperatures may require lower viscosity oil. From the factory, the shocks

are filled with 20W silicone oil. Only use 100% silicone oil in the shock.

Replacing Shock Oil

The shocks have to be removed from

the vehicle and disassembled to

change the oil.

1. Remove the lower spring retainer

and shock spring.

2. Remove the upper shock cap.

3. Empty the used shock oil from the

shock body.

4. Compress the shock fully against

the stop on the lower spring

retainer (A).

5. Fill the shock with new silicone

shock oil up to the top of the shaft;

then, add 2-3 drops of oil to reach

the proper level (0.3mm above the

top of the shaft) (B).

6. Slowly move the piston up and

down to remove excess air. Add

oil if needed to maintain the

proper level.

7. Ensure the cavity in the upper shock

cap (C) is dry and free of oil; screw

the shock cap onto the shock body.

8. Tighten the shock cap until snug.

Shock disassembly

The shocks must be removed from the vehicle prior to disassembly.

Use the shock exploded views included with the model to aid in the

assembly process.

1. Remove the spring and lower spring retainer from the shock.

2. Remove the shock cap and empty the shock body of shock oil.

3. Remove the lower cap, the X-rings, and spacer from the shock

body.

4. Use needlenose pliers or side cutters to grip the shock shaft just

above the rod end. Remove the rod end from the shock shaft.

5. Remove the shock shaft with piston from the shock body out

through the top of the shock body.

A

B

6.7mm

C

Summary of Contents for 82034-4

Page 1: ...MODEL 82034 4 owner s manual EQUIPPED WITH ...

Page 31: ...TRX 4 31 ...