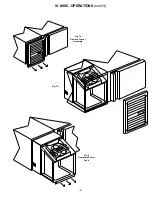

V. c - REPLACING THE GASKETS:

To remove the gasket to be replaced, grasp it firmly by

one corner and pull it out. Before attempting to install

a new gasket, both the unit and the gasket itself must

be at room temperature. Insert the four corners first

by using a rubber mallet (or hammer with a block of

wood). After the corners are properly inserted, work

your way towards the center from both ends by gently

hitting with a mallet until the gasket is completely

seated in place (see figure 5 for proper gasket place-

ment).

NOTE: The gasket may appear too large, but if it is

installed as indicated above it will slip into place.

V. d - CLEANING THE EXTERIOR:

Exterior stainless steel should be cleaned with warm

water, mild soap and a soft cloth. Apply with a damp-

ened cloth and wipe in the direction of the metal grain.

Avoid the use of strong detergents and gritty, abra-

sive cleaners as they may tend to mar and scratch the

surface. Do NOT use cleansers containing chlorine,

this may promote corrosion of the stainless steel.

Care should also be taken to avoid splashing the unit

with water, containing chlorinated cleansers, when

mopping the floor around the unit.

For stubborn odor spills, use baking soda and water

(mixed to a 1 TBSP baking soda to 1 pint water ratio).

V. e - CLEANING THE INTERIOR:

For cleaning both stainless steel and anodized alumi-

num interiors, the use of baking soda as described in

section

“

V. d

”

is recommended. Use on breaker strips

as well as door gaskets. All interior fittings are re-

movable without tools to facilitate cleaning.

WARNING: DISCONNECT ELECTRICAL POWER

SUPPLY BEFORE CLEANING ANY PARTS OF THE

UNIT.

VI. MISC. OPERATIONS

VI. a - ADJUSTING THE SHELVES:

For shelves mounted on pins, first select the desired

location and remove the white plastic covers in the

interior back and sides by rotating them counter-clock-

wise. Remove the shelf pins by rotating them counter-

clockwise. Install the pins in the desired location by

-4-

IV. b - FREEZERS (cont

’

d):

trols function upon termination of a defrost cycle is

two-fold. First, to prevent blowing warm air into the

food storage area. Second, to prevent any conden-

sation on the defrost coil from being blown into the

food storage area.

The INTELA-TRAUL control is set from the factory to

terminate defrost at 20 minutes in the event of a sen-

sor failure. This setting should never be tampered

with, without first consulting the factory.

IV. c - CONDENSATE REMOVAL:

Both refrigerator and freezer units are supplied with

an electric condensate evaporator for condensate re-

moval.

V. CARE & MAINTENANCE

V. a - CLEANING THE CONDENSER:

The most important thing you can do to insure a long,

reliable service life for your Traulsen is to regularly

clean the condenser coil.

The condensing unit requires regularly scheduled

cleaning to keep the finned condenser clean of lint

and dust accummulation. The INTELA-TRAUL con-

trol will notify you through a

“

CLN-FIL

”

message when

cleaning is necessary (see page 7). Keeping the con-

denser clean allows the cabinet to operate more effi-

ciently and use less energy.

To clean the condenser, first disconnect electrical

power to the cabinet and remove the front louver as-

sembly. To remove this, follow the directions in sec-

tion VI. d - Step #1. Once the screws are removed, the

panel can be removed allowing full access to the

powerpack. Vacuum or brush any dirt, lint or dust

from the finned condenser coil, the compressor and

other cooling system parts. If significant dirt is clog-

ging the condenser fins, use compressed air to blow

this clear.

Replace louver assembly, screws and caps.

V. b - HINGE REPLACEMENT:

Both the door and hinge can be easily removed from

the cabinet. To remove the door, remove the plug at

the bottom of the top hinge. Inside the hinge there is

a small screw which secures the door in place. Re-

move this with a flat head screwdriver and the door

can then be lifted off the hinge. To remove the door

half of the hinge from the door, lift off the hinge cover

and then remove the three Phillips head screws which

secure the hinge in place on the door. To remove the

cabinet half of the hinge, remove the three Phillips

head screws which hold it in place. To reassemble

the hinge reverse the previous procedure.

IV. OPERATION

(continued)

V. CARE & MAINTENANCE

Fig. 5

○

○

○

○

Inside Door Panel

Gasket Assembly

Vertical Gasket

Retainer

○

○

○

○

○

○

○

○

○

○