32

CNT-SVX08F-EN

PID Control

Derivative Calculation

The derivative calculation responds to the change in error. In other words, it responds to how

quickly the measured value is approaching setpoint. The derivative calculation can be used to

smooth an actuator motion or cause an actuator to react faster.

However, derivative control has several disadvantages:

•

It can react to noise in the input signal.

•

Setting derivative control requires balancing between two extremes; too much derivative gain

and the system becomes unstable, too little and the derivative gain has almost no effect.

•

The lag in derivative control makes tuning difficult.

•

Large error deadbands, common in HVAC applications, render derivative control ineffective.

Because of these disadvantages, derivative control is rarely used in HVAC applications. The

exception are steam valve controllers which use derivative control to force the steam valve to react

faster to changes.

Throttling Range and Gain

The throttling range is the amount of error it takes to move the output of a system from its minimum

to its maximum setting. It determines the sensitivity of a control system to disturbances. The

smaller the throttling range, the more sensitive and responsive a system will be.

Think of the throttling range as the point at which the system will apply all if its

muscle

to bring

the error back to zero. For example, a throttling range of 2°F (1.1°C) means that a controller will use

all of its power to bring the error to zero when the error is 2°F (1.1°C) or greater. Control becomes

looser as the throttling range increases. Throttling range cannot be programmed directly in a

control system; rather, it is used to calculate the gains (refer to the next section,

).

Gain determines how fast a system moves toward the setpoint. The larger the gain, the more

aggressive the system will be. The proportional, integral, and derivative calculations each have an

associated gain value. The error (proportional), the sum of past errors (integral), and the change

in error (derivative) are multiplied by their associated gains to determine the impact that each has

on the output. As the throttling range increases, the gain decreases and the potential error

increases.

Calculating the Gain

shows the recommended initial values for the proportional and integral gains. Most

applications do not require a derivative contribution, so derivative gain is not shown—it is set to

zero.Trane recommends using a ratio of 4:1 for the proportional and integral gains. Therefore, the

proportional gain should be four times as large as the integral gain. It may be necessary to modify

the values shown in

when tuning a PID loop, but always try to maintain the 4:1 ratio.

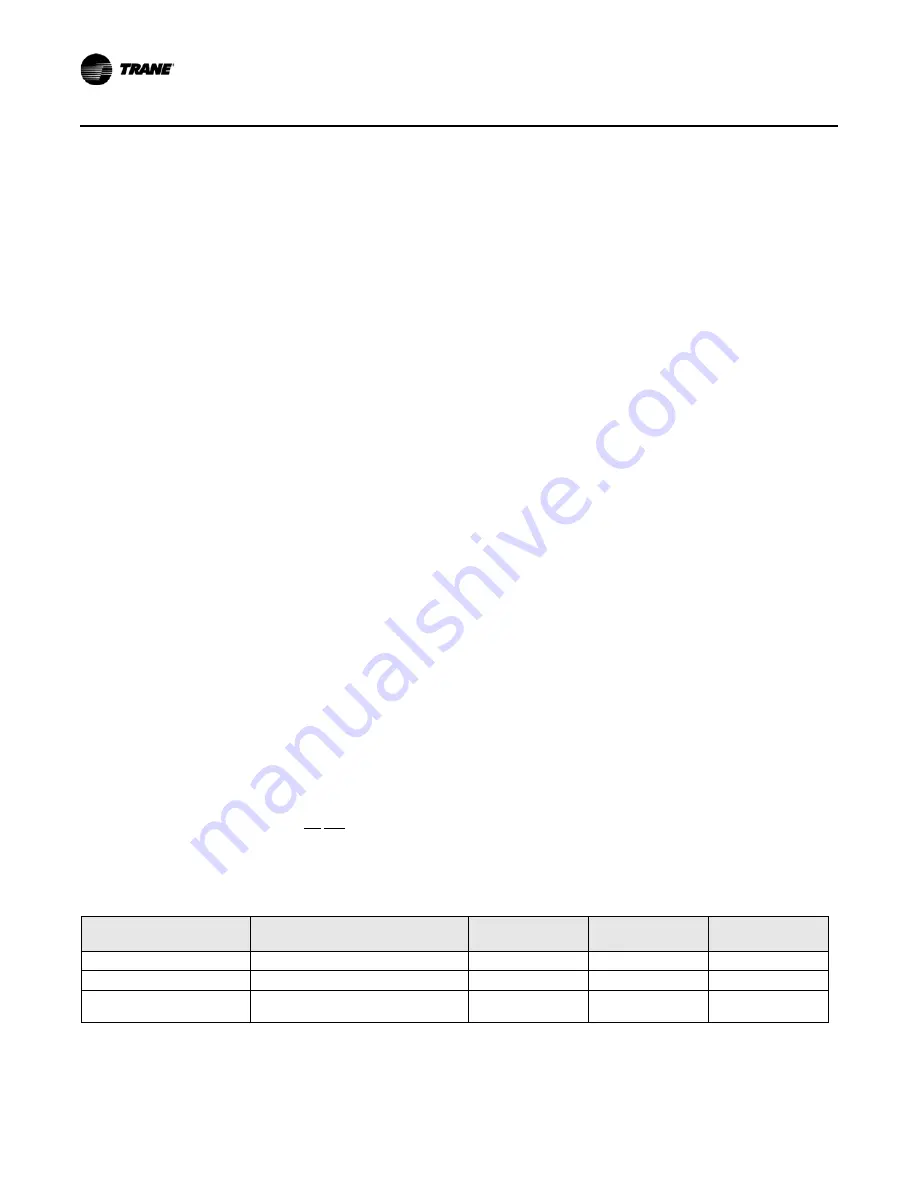

Table 7.

Starting gain values for applications

Loop

Output

Throttling

Range

Proportional

Gain

Integral

Gain

Discharge air cooling

Valve position 0–100%

20.0°F (11.1°C)

4.0 (8.0)

1.0 (2.0)

Discharge air heating

Valve position 0–100%

40.0°F (22.2°C)

2.0 (4.0)

0.5 (1.0)

Space temperature

Discharge setpoint

50–100°F (10–37.8°C)

2.0°F (1.1°C)

20.0 (20.0)

5.0 (5.0)