Troubleshooting

RT-SVX22J-EN

55

The RTRM will ignore the closing of this Normally Open

switch for 2 (±1) minutes. This helps prevent nuisance

SERVICE LED indications. The exception is the LED will

flash 40 seconds after the fan is turned “On” if the Fan

Proving Switch is not made.

Clogged Filter Switch

This LED will remain lit the entire time that the Normally

Open switch is closed. The LED will be turned off

immediately after resetting the switch (to the Normally

Open position), or any time that the IDM is turned “Off”.

If the switch remains closed, and the IDM is turned “On”,

the SERVICE LED will be turned “On” again after the 2 (±1)

minute ignore delay.

This LED being turned “On”, will have no other affect on

unit operation. It is an indicator only.

Fan Failure Switch

When the “Fan Failure” switch is wired to the RTOM, the

LED will remain flashing the entire time the fan proving

switch is closed, indicating a fan failure, and it will shut the

unit operations down.

Condensate Overflow Switch

When the “Condensate Overflow Switch" is closed, a drain

pan overflow condition is indicated and it will shut unit

operations down.

Zone Temperature Sensor (ZTS)

Test

Note:

These procedures are not for programmable or

digital models and are conducted with the Zone

Sensor Module electrically removed from the

system.

Test 1 - Zone Temperature Thermistor

(ZTEMP)

This component is tested by measuring the resistance

between terminals 1 and 2 on the Zone Temperature

Sensor. Below are some typical indoor temperatures, and

corresponding resistive values.

Test 2 - Cooling Set Point (CSP) and

Heating Set Point (HSP)

The resistance of these potentiometers are measured

between the following ZSM terminals. Refer to the chart

above for approximate resistances at the given setpoints.

Cool SP = Terminals 2 and 3

Range = 100 to 900 Ohms approximate

Heat SP = Terminals 2 and 5

Range = 100 to 900 Ohms approximate

Test 3 - System Mode and Fan Selection

The combined resistance of the Mode selection switch and

the Fan selection switch can be measured between

terminals 2 and 4 on the Zone Sensor. The possible switch

combinations are listed below with their corresponding

resistance values.

Test 4 - LED Indicator Test, (SYS ON, HEAT,

COOL & SERVICE)

Method 1

Testing the LED using a meter with diode test function. Test

both forward and reverse bias. Forward bias should

measure a voltage drop of 1.5 to 2.5 volts, depending on

your meter. Reverse bias will show an Over Load, or open

circuit indication if LED is functional.

Method 2

Testing the LED with an analog Ohmmeter. Connect

Ohmmeter across LED in one direction, then reverse the

leads for the opposite direction. The LED should have at

least 100 times more resistance in reverse direction, as

compared with the forward direction. If high resistance in

both directions, LED is open. If low in both directions, LED

is shorted.

Method 3

To test LED’s with ZSM connected to unit, test voltages at

LED terminals on ZSM. A measurement of 32 VDC, across

an unlit LED, means the LED has failed.

Relative Humidity Sensor Test

This component is measured by measuring the mA output

signal on the Relative Humidity Sensor. Verify accuracy of

the sensor annually. If the output reading is 0 mA, first

verify that power is applied to the sensor. A reading of 4

mA corresponds to 0% RH and 20 mA corresponds to 100%

RH.

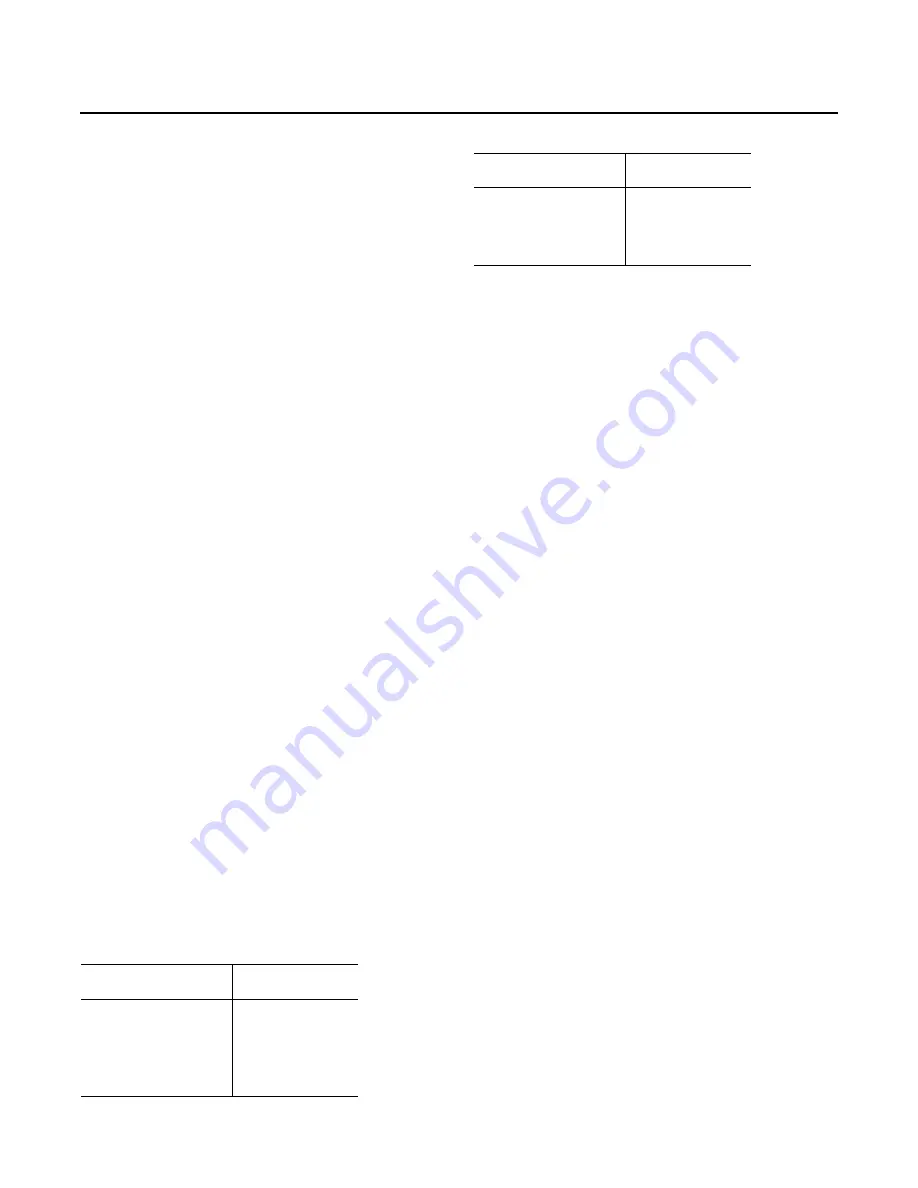

Table 14. Cooling setpoint and heating setpoint

Zone Temperature

Nominal ZTEMP

Resistance

50° F

10.0°C

19.9 K-Ohms

55° F

12.8°C

17.47 K-Ohms

60° F

15.6°C

15.3 K-Ohms

65° F

18.3°C

13.49 K-Ohms

70° F

21.1°C

11.9 K-Ohms

75° F

23.9°C

10.50 K-Ohms

80° F

26.7°C

9.3 K-Ohms

85° F

29.4°C

8.25 K-Ohms

90° F

32.2°C

7.3 K-Ohms

Table 14. Cooling setpoint and heating setpoint

Zone Temperature

Nominal ZTEMP

Resistance

Summary of Contents for Precedent THC036E

Page 37: ...Installation RT SVX22J EN 37 Figure 51 Examples...

Page 63: ......